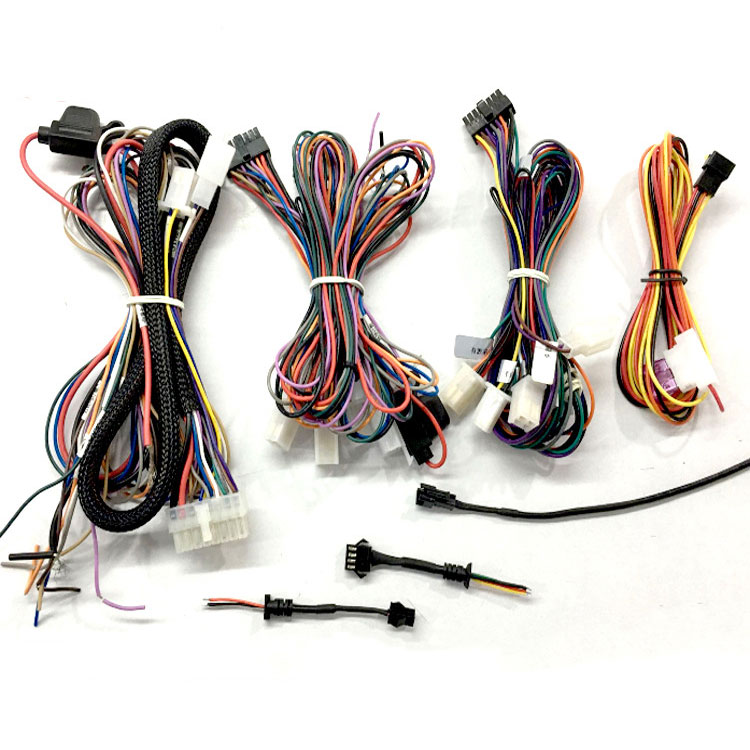

Overmolded, Molded, and Injection Molded Cable Assemblies

Overmolded and Injection Molded Cable Assemblies

YCable is a highly experienced professional manufacturer of overmolded cable assemblies in China, delivering reliable and durable solutions for various industries.

Overmolded Cable Assemblies

- Protective material is molded over cable connections for enhanced durability.

- Provides strain relief, waterproofing, and resistance to harsh environments.

- Ideal for medical, industrial, and automotive applications.

Molded Cable Assemblies

- General term for cables with molded connectors.

- Enhances mechanical strength, aesthetics, and longevity.

- Can be produced using different molding techniques, including overmolding.

Injection Molded Cable Assemblies

- Uses injection molding to form precise, durable connectors.

- Ensures strong adhesion and repeatable, high-volume production.

- Suitable for custom cable designs with complex requirements.

YCable’s expertise in overmolded cable assemblies guarantees high-quality, reliable solutions tailored to specific customer needs.

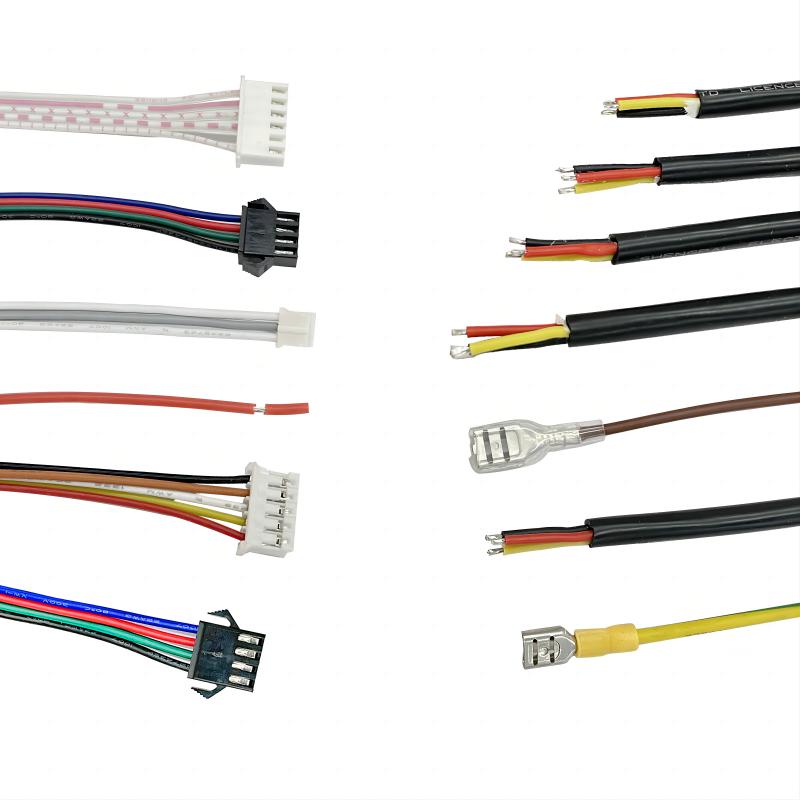

YCABLE’s Expertise in Wire, Cable, and Overmolded Assemblies

YCABLE is a highly specialized company with extensive expertise in wire and cable engineering. This deep knowledge enables YCABLE to analyze customer drawings and specifications to identify significant cost-saving opportunities in wire and cable selection for overmolded, injection molded, or molded cable assemblies.

With a comprehensive understanding of various wire and cable compounds, YCABLE’s engineers provide expert guidance in selecting the optimal overmold or molding compound tailored to specific applications. Ensuring that the final assembly performs as intended—both electronically and mechanically—requires thorough consideration of the physical environment and end-use conditions. By factoring in these critical elements, YCABLE helps customers choose the most suitable materials for their applications.

YCABLE’s on-site manufacturing capabilities include a Mini-Jector Model 55P, enabling in-house production of overmolded and injection molded assemblies. This vertical integration allows YCABLE to maintain complete control over the cable assembly process, ensuring that every finished product meets the company's rigorous quality standards while enhancing efficiency and reducing lead times.

Advanced Manufacturing Expertise

- Decades of experience in precision overmolding and injection molding.

- Customization capabilities for unique design requirements.

High-Quality Materials & Durability

- Use of premium thermoplastics, polyurethane, and other robust materials.

- Excellent strain relief, waterproofing, and resistance to harsh conditions.

Precision Engineering & Consistency

- State-of-the-art molding techniques ensuring strong adhesion and repeatability.

- Strict quality control for defect-free, high-performance assemblies.

Cost-Effective & Scalable Production

- Efficient manufacturing processes for both low and high-volume production.

- Competitive pricing without compromising quality.

Industry-Specific Custom Solutions

- Expertise in automotive, medical, industrial, and consumer electronics applications.

- Design support for complex geometries, connectors, and environmental requirements.

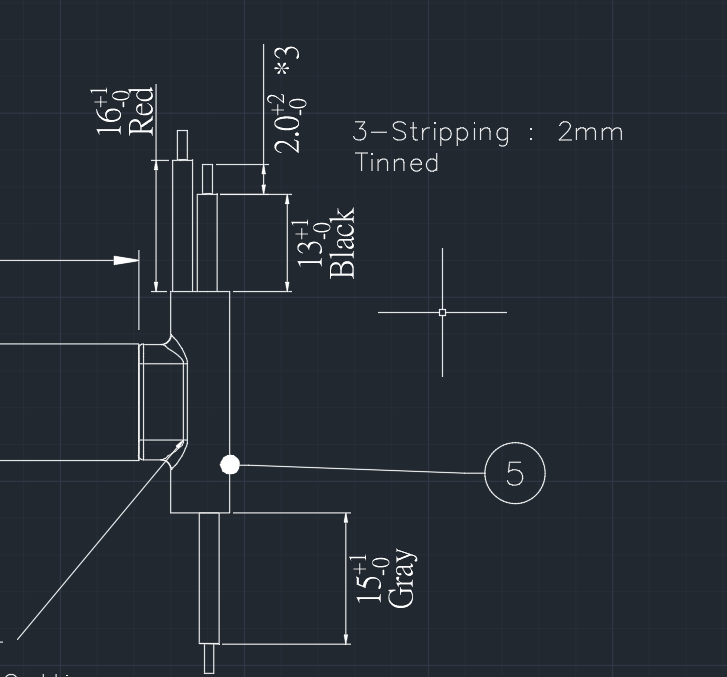

Quality Control Processes at YCABLE for Overmolded Cable Assemblies

YCABLE follows a rigorous quality control system to ensure that every overmolded cable assembly meets the highest industry standards. Our quality assurance processes include:

Raw Material Inspection

- Verification of wire, cable, and overmold compounds for compliance with specifications.

- Testing for material durability, flexibility, and environmental resistance.

In-Process Quality Checks

- Dimensional accuracy checks using precision measuring tools.

- Visual inspections to detect defects like air pockets, improper molding, or misalignment.

- Process control monitoring to ensure consistent injection molding parameters.

Electrical Performance Testing

- Continuity testing to verify proper electrical connections.

- High-voltage (Hi-Pot) testing for insulation integrity.

- Resistance and impedance testing to ensure optimal signal transmission.

Mechanical & Environmental Testing

- Pull force testing to assess strain relief and mechanical strength.

- Flex life testing to simulate repeated bending and movement.

- Temperature and environmental simulations for heat, moisture, and chemical resistance.

Final Inspection & Compliance Verification

- 100% final product inspection for appearance, functionality, and durability.

- Compliance with UL, RoHS, REACH, and industry-specific standards.

- Custom testing based on client-specific requirements.

FAQs About Overmolded and Molded Cable Assemblies

What is an Overmolded Cable Assembly?

An overmolded cable assembly is a cable with a protective layer molded over the connectors or junction points. This process enhances durability, strain relief, and environmental resistance.

How Does Overmolding Improve Cable Assemblies?

Overmolding provides:

Strain relief to prevent cable fatigue

Environmental protection (waterproof, dustproof, chemical resistance)

Mechanical strength for durability in harsh conditions

Enhanced aesthetics and branding opportunities

What Is the Difference Between Overmolded and Molded Cable Assemblies?

Overmolded Cable Assemblies: Feature an additional protective layer molded over cable connectors for extra durability and sealing.

Molded Cable Assemblies: A broader term that includes any cable assembly where connectors or junctions are encased in molded material, including overmolding and injection molding techniques.

What Are the Common Materials Used in Overmolding?

Materials include:

Thermoplastic Elastomers (TPE) – Flexible and durable

Polyvinyl Chloride (PVC) – Cost-effective and widely used

Polyurethane (PU) – Resistant to abrasion and chemicals

Silicone – Ideal for medical and extreme environments

What Industries Use Overmolded Cable Assemblies?

Medical – Sterile, biocompatible, and durable solutions

Automotive – High-temperature and vibration-resistant cables

Industrial – Waterproof and ruggedized designs for harsh environments

Consumer Electronics – Custom branding and flexible designs

What Are the Benefits of Injection Molded Cable Assemblies?

Injection molding ensures:

Precision and consistency in mass production

Strong material adhesion for durability

Custom designs for complex shapes and integrated strain relief

Can Overmolded Cable Assemblies Be Customized?

Yes, overmolded assemblies can be fully customized with:

Custom shapes, sizes, and colors

Branding elements like logos

Specific material choices for unique applications

How Do I Choose the Right Overmolded or Molded Cable Assembly?

Key factors to consider:

Application environment (temperature, moisture, chemicals)

Flexibility and strain relief needs

Electrical and mechanical performance requirements

Regulatory compliance (UL, RoHS, IP ratings, etc.)