Custom Overmolded Cable Assemblies

Custom Overmolded Cable Assemblies

Item Number:Custom Over Molded Cable Assemblies

- Cable: Custom

- Connector: Custom

- Injection Molding: Custom

- Injection Material: PVC, Nylon, Custom

- Strip: Custom

- Packing: Carton, Custom

- Length: Custom

- Service: OEM/ODM, Accepting customization, providing design, drawing and production samples, accepting small batch orders

Environmental Specifications:

Environmental Space – Non-plenum

Flame Test Method – CMR

Installation Temperature – 0 °C to +60 °C (+32 °F to +140 °F)

Operating Temperature – -20 °C to +60 °C (-4 °F to +140 °F)

General Specifications:

Cable Type

Custom Overmolded Cable Assemblies

Pairs, quantity

Custom

Cable Component Type

Horizontal/Custom

Conductor Gauge, singles

24AWG/Custom

Conductor Type, singles

Solid/Stranded/Custom

Characteristics:

- Custom Overmolded Cable Assemblies

Custom Overmolded Cable Assembly

Categories

Custom Overmolded Cable Assemblies

| Electrical Specifications | |

| Item | Custom Overmolded Cable Assemblies |

| Cable Size | Custom |

| Cable Length | Custom |

| Connector | Custom |

| Overmolding Design | Custom |

| Overmold Tooling Materials | PVC/PE/PUR/Custom |

| Operating Voltage, maximum | 80 V/Custom |

| Standards | ISO9001 |

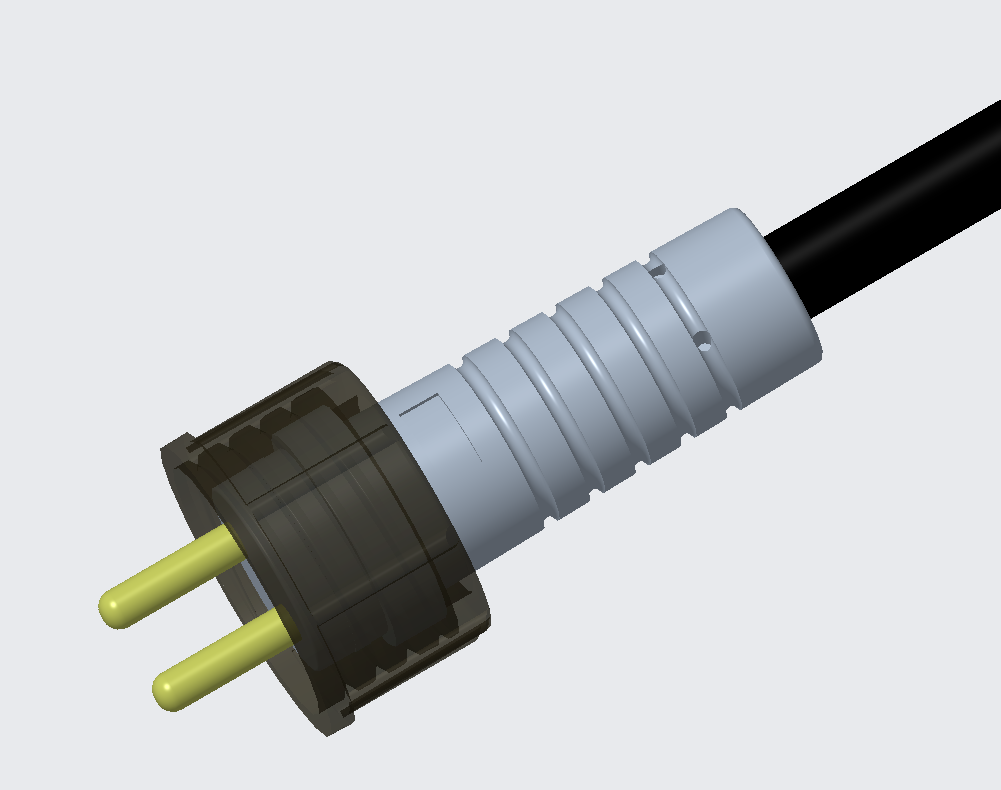

| Waterproof | IP66 IP67 IP68 / Custom |

Description

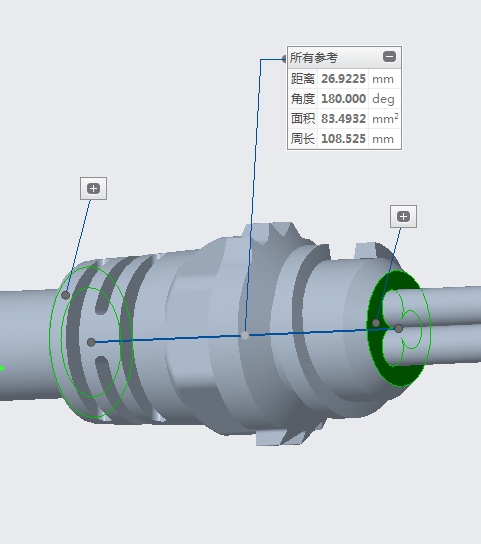

Custom Overmolded Cable Assemblies

At YCABLE ELECTRONICS, we stand at the forefront of creating bespoke overmolded cable assemblies, encapsulated components, and overmolded parts for a diverse range of sectors. Our adeptness spans from modest to substantial production runs, bolstering YCABLE ELECTRONICS as the go-to specialist for precision overmolding solutions.

Dedication to Overmolded Cable Assembly Excellence

Unlike many in the cable manufacturing arena, custom overmolded or injection molded cable assemblies are at the core of our mission, not a mere supplementary service. YCABLE ELECTRONICS prides itself on its unwavering commitment to delivering top-tier custom overmolded cable assemblies that elevate our clients' operational efficiency and profitability.

Our prowess in overmolded assemblies surpasses that of competitors, many of whom might offer limited overmold capabilities. Our leadership in the field is underscored by our robust infrastructure, featuring over nine dedicated overmold stations ready to cater to your specific requirements.

From Idea to Implementation

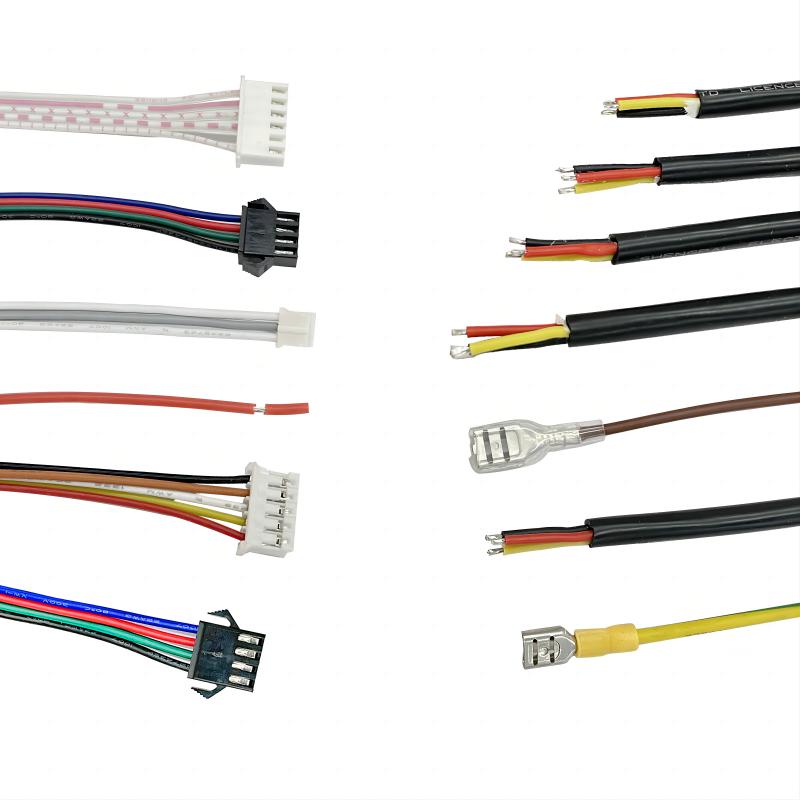

The team at YCABLE ELECTRONICS is relentless in ensuring that your components are crafted to meet the precise requirements set forth by your engineering division. We offer an extensive selection of encapsulating materials to fulfill your project needs, including:

- PVCs (Polyvinyl Chloride)

- TPVs (Thermoplastic Vulcanizate)

- TPRs (Thermoplastic Rubber)

- TPE (Thermoplastic Elastomer)

- LCPs (Liquid Crystal Polymer)

- Technomelts

Moreover, YCABLE ELECTRONICS enriches your overmolding options with an array of molded connector choices—ranging from D-subs and circular connectors to mini-din and ferrites, among others—and further customization options such as grommets, backshells, and more. Our encapsulation solutions cover low-pressure molding, potting, and conformal coating to safeguard circuit boards and other components, alongside options for imprinting your brand identity on most overmolded cable assemblies.

Advantages of Our Overmolded Assemblies

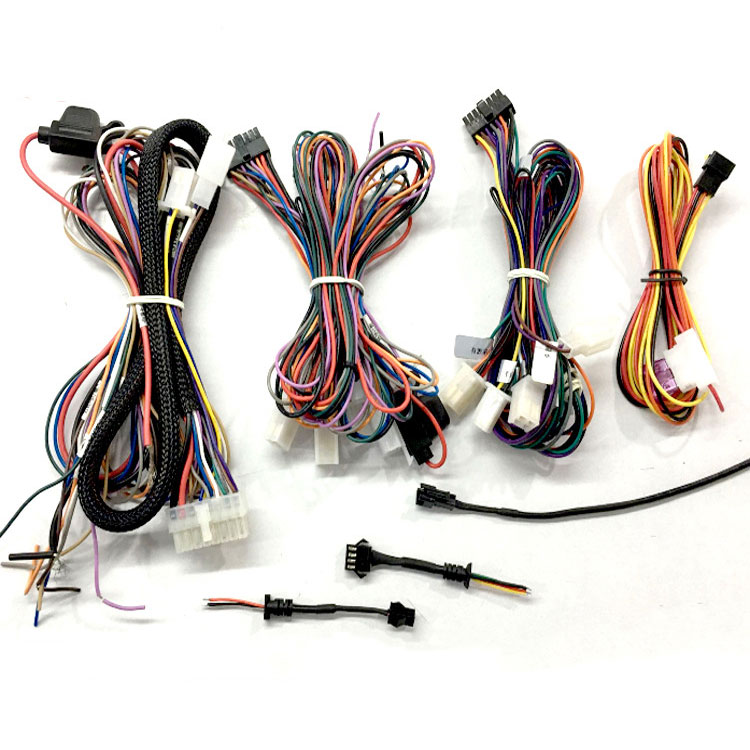

Custom overmolded assemblies from YCABLE ELECTRONICS are engineered to excel in challenging or corrosive environments, meeting strict performance criteria. Our engineering team is adept at designing overmolded and encapsulated components that stand up to the most rigorous conditions. For applications requiring high levels of ingress protection, such as IP67 or IP68, we tailor solutions with the appropriate selection of materials, cables, wires, and connectors.

As a comprehensive contract manufacturer, YCABLE ELECTRONICS extends a plethora of manufacturing processes and additional services aimed at boosting your productivity and profitability. Our end-to-end contract manufacturing solutions, from design and custom overmolding to assembly, packaging, and testing, ensure the delivery of dependable assemblies within your timelines.

The specification of an overmolded cable assembly is a routine requirement for projects within industries that demand robustness and reliability, such as industrial settings, heavy-duty commercial applications, and sectors requiring high reliability (like medical, defense, and aerospace). Those involved in electrical cable and wire assembly design usually have a clear vision of the anticipated appearance of a completed cable assembly, often illustrated as a standard reference.

Related Products

M12 Connector Waterproof Cable Assembly

In the sphere of M12 cables and connectors, we see a deliberate ...

DT Connector Overmolded Cable Assembly

DT connector cable assemblies, crafted by DEUTSCH, are specialized for creating resilient, ...

M6 Connector Waterproof Cable Assembly

At YCABLE ELECTRONICS, our dedication to excellence in the field of waterproof ...

Overmolded OBD Extension Cable Assembly

An OBD cable is essentially a device linked to on-board diagnostics or ...