Best Solar PV DC Cable Solar Panel Extension Cable Manufacturer in China Suppliers 4mm 6mm 10mm

Download Solar Cable Catalog

What is solar cable? What is PV cable?

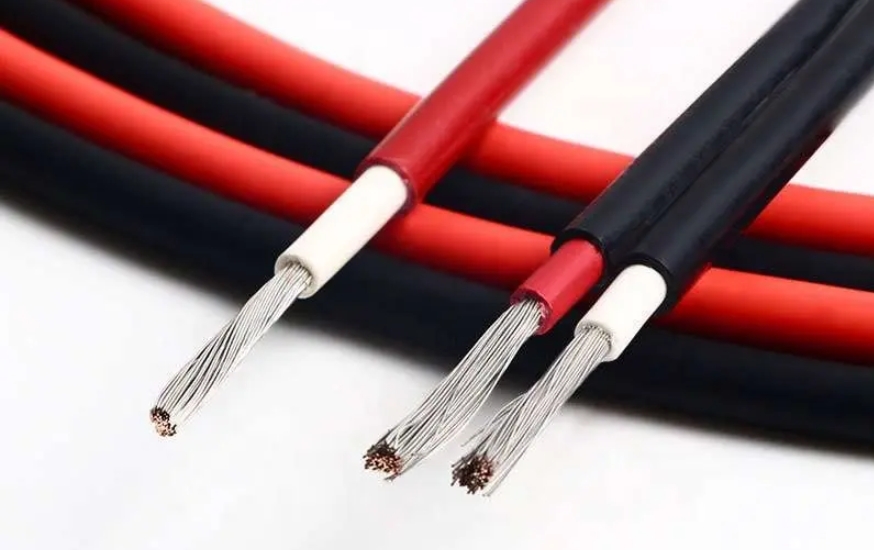

What are the common solar pv cable in our lives? In fact, the so-called pv cable are special products for solar solar cable. The models usually include PV1-F and H1Z2Z2-K. As the world's focus on renewable energy continues to increase, solar power generation plays a very important role, and solar cables are increasingly used in the field of solar power generation.

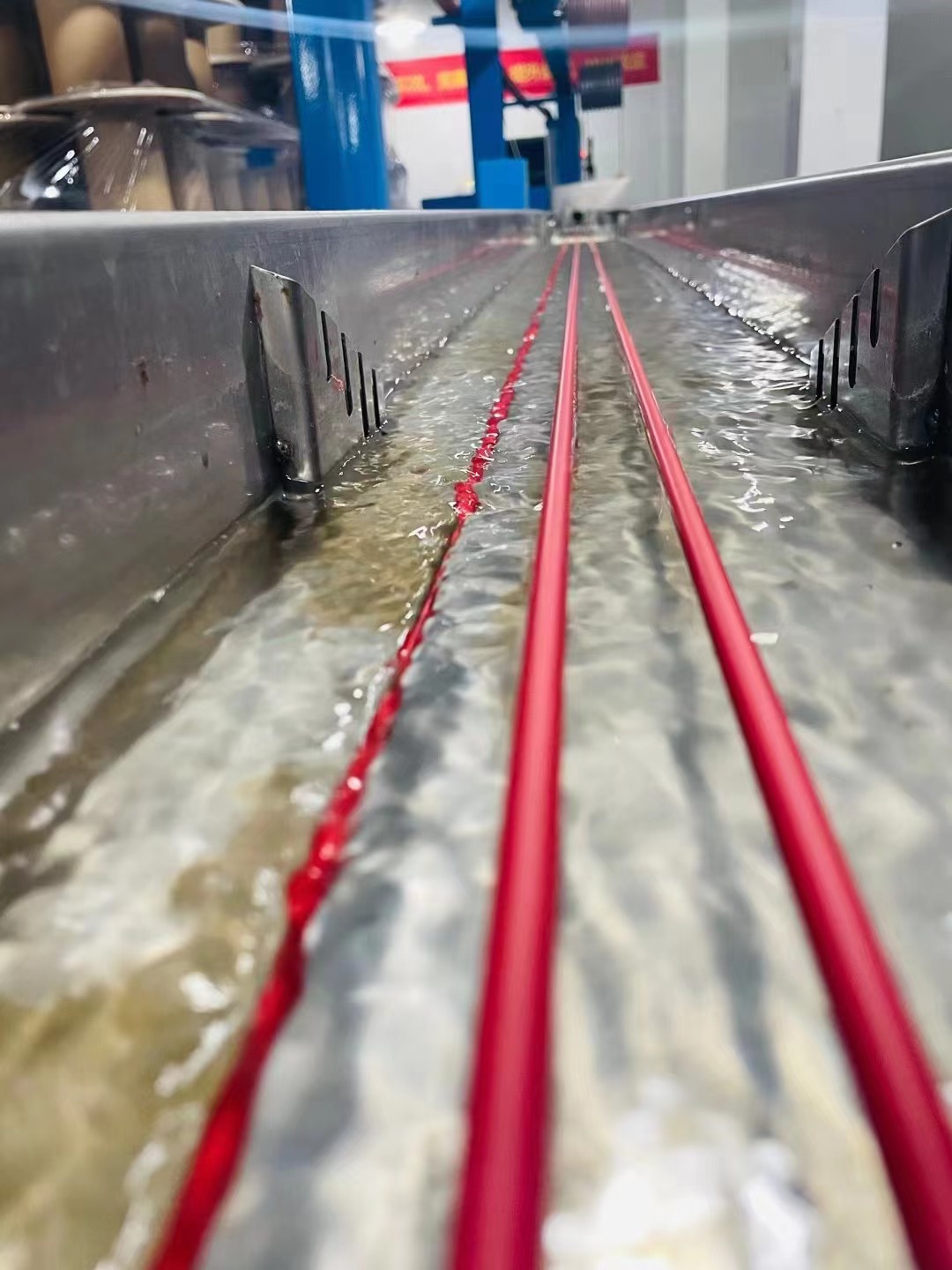

Solar cable is a special cable used in solar solar module systems. The solar cable has the characteristics of weather resistance, high temperature resistance, friction resistance, ultraviolet radiation resistance, ozone resistance, hydrolysis resistance, acid resistance, salt resistance, etc., and solar pv cable has an extra long Service life, high-performance insulation materials and sheath materials after high-energy electron accelerator radiation exchange play a reliable insulation performance and mechanical properties. solar cables also offer higher electrical performance. In solar power generation systems,solar cable need to transmit large currents and voltages, so solar cable have electrical properties such as lower resistance and higher withstand voltage levels, which can ensure the transmission performance and safety of the cables.

Solar cable are also divided into monocrystalcable silicon solar cable, polycrystalcable silicon solar cable, and amorphous silicon solar cable.

In short, solar cable, as important components connecting solar power generation systems, will play an increasingly important role in the future energy field. With the continuous advancement of technology and the continuous expansion of application scenarios, solar cable will continue to innovate and develop, making greater contributions to promoting the development of green energy.

What gauge is solar cable?

Specificaiton of solar cable

|

No. Of cores x Construction (mm2) |

Conductor Construction (n / mm) |

Conductor No./mm |

Insulation. Thick. (mm) |

Current Aarring Capacity (A) |

|

1x1.5 |

30/0.25 |

1.58 |

4.9 |

30 |

|

1x2.5 |

49/0.25 |

2.06 |

5.45 |

41 |

|

1x4.0 |

56/0.3 |

2.58 |

6.15 |

55 |

|

1x6 |

84/0.3 |

3.15 |

7.15 |

70 |

|

1x10 |

142/0.3 |

4.0 |

9.05 |

98 |

|

1x16 |

228/0.3 |

5.7 |

10.2 |

132 |

|

1x25 |

361/0.3 |

6.8 |

12.0 |

176 |

|

1x35 |

494/0.3 |

8.8 |

13.8 |

218 |

|

1x50 |

418/0.39 |

10.0 |

16.0 |

280 |

|

1x70 |

589/0.39 |

11.8 |

18.4 |

350 |

|

1x95 |

798/0.39 |

13.8 |

21.3 |

410 |

|

TYPE |

cable STRUCT(mm) |

CONDUCTOR DIA.(mm) |

OUTER DIA.(mm) |

|

2*2.5mm² |

49/0.25 |

2.0 |

6.2*9.9 |

|

2*4.0mm² |

56/0.30 |

2.6 |

6.9*11.3 |

|

2*6.0mm² |

84/0.30 |

3.3 |

7.1*14.5 |

|

2*10mm2 |

142/0.3 |

|

|

What is the difference between solar cable and normal cable?

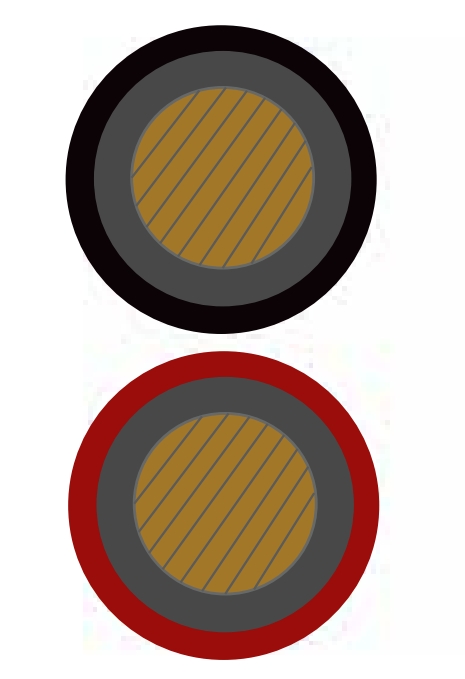

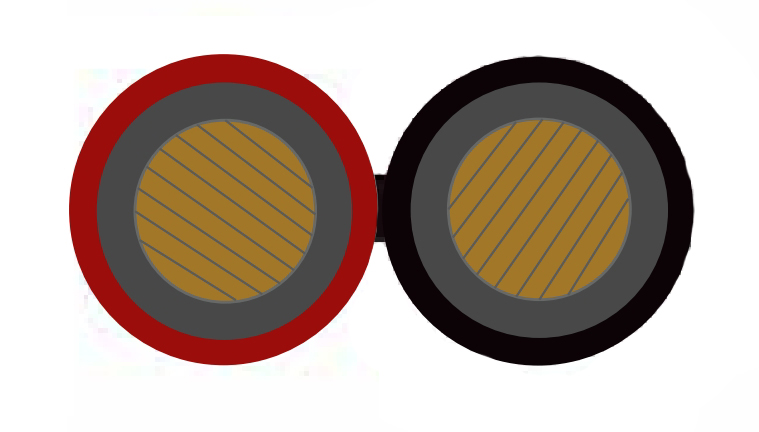

Firstly, in terms of conductor material, both solar and household cables use conductors or tinned copper conductors, and there is not much difference between the two. Secondly, there is a significant difference between the two in terms of insulation sheath. solar cables use irradiation cross-linked polyolefin insulation protective sleeves. Usually, irradiated cross-linked polyolefins have strong environmental adaptability, chemical corrosion resistance, mechanical tensile resistance, and high temperature resistance, with a maximum rated temperature of up to 120 ° C

The PVC sheath used for ordinary cables also has certain environmental resistance but is not resistant to high temperature and low cold, so it is usually not suitable for outdoor use. Usually used for indoor wiring, it can achieve a relatively stable effect, while solar cables need to be used in harsh outdoor environments.

Conductor

- solar cable: copper conductor or tinned copper conductor

- Ordinary cable: copper conductor or tinned copper conductor

Insulation

- solar cables: irradiation cross-linked polyolefin insulation

- Ordinary cable: polyvinyl chloride (PVC) or cross-linked polyethylene insulation

Sheath

- solar cables: irradiation cross-linked polyolefin insulation

- Ordinary cable: PVC sheath

What is the best cable for solar installation?

Through the above introduction, we can find that solar cables and ordinary cables are consistent on the conductor, and their difference is that their insulation layer and sheath material are different.

Irradiated cross-linked polyolefins have strong environmental adaptability, chemical corrosion resistance, creep resistance, and high temperature resistance, with a maximum rated temperature of 125 ℃.

PVC has the advantages of stable structure, high chemical resistance, good mechanical strength and insulation properties, but its stability to light and heat is poor, with a maximum rated temperature of 105 ℃.

Crosslinked polyethylene is a network structure with excellent heat resistance. Its insulation performance is also higher than that of PE material. The hardness, stiffness, wear resistance, and impact resistance of mechanical properties have all been improved. Chemical resistance, strong acid alkali resistance, and oil resistance. The maximum rated temperature is 90 ℃.

Due to the particularity of solar power generation systems, there are special requirements for solar cables. solar cables need to be weather resistant, high-temperature resistant, friction resistant, UV resistant, ozone resistant, hydrolysis resistant, acid resistant, salt resistant, etc., and irradiation cross-linked polyolefins meet this characteristic. Polyvinyl chloride (PVC) or cross-linked polyethylene insulation has slightly lower heat resistance than irradiation cross-linked polyolefin insulation, so ordinary cables cannot be applied to solar cables.

Therefore, the best insulator and sheath material for solar cables is irradiated cross-linked polyethylene

Solar cable application field.

solar cables refer to application cable cables that use non solar solar power generation. With the continuous development of solar solar power generation technology, the application range of solar cables is also becoming increasingly widespread.

The main purpose of solar cables is to connect solar panels and inverters, converting the direct current generated by solar panels into alternating current, and supplying power to households Enterprises and public facilities, etc. The characteristic of solar cables is that they have high heat resistance, cold resistance, and UV resistance, and can operate stably in various harsh environments.

In addition to being used for solar solar power generation, solar cables can also be applied in other fields. For example, in the field of architecture, solar cables can be used in solar solar power generation systems at locations such as exterior walls, roofs, and balconies to provide clean energy for buildings. In the field of transportation, solar cables can be used in solar solar road lighting systems to provide lighting and safety for roads

Solar panels: solar cables can transmit the electricity generated by solar panels to external circuits, thereby achieving the collection and utilization of electricity.

Wind power generation: The blades in wind turbines need to transmit the generated electricity to the grid through solar cables, which play a crucial role here.