All Products

Who we are?

Ycable Electronics provides solutions for a wide range of cables, wires, cable assemblies, and wire harnesses. We always adhere to quality first, honest management, equality, and mutual benefit, and achieve common progress. We receive OEM orders for wires, cables, wire harnesses, and cable assembly, We have rich experience and can provide you with more help. We have a research and development design team that provides you with multiple options to choose from and uses our experience to help you avoid some problems.

We are a continuous learning and progress company, We strive for excellence in our areas of expertise and constantly expand into new areas. Only through continuous learning and progress can we provide stable and better service to our customers. hoping to grow together with our customers.

What cable and wire can we provide?

We provide customized cables according to different requirements and usage environments, Using different materials, shapes, and combinations to meet specific needs or match certified cables and wires of different standards, like UL certification wires, VDE wires, SAA cables, and so on. We now have ethernet cables, audio cables, coaxial cables, shielding cables, solar cables, hook-up wires, high-temperature wires, and power cables.

How to manufacture cables and wires?

- We need to prepare the material for the conductor and insulation.

- We need to combine the conductors together, so we strand them together, which is beneficial for being insulated, If you need to increase the adhesion between the conductor and insulation, we need to preheat the conductor before adding insulation.

- We extruded the insulation, we add different plastic particles, and melt them into shape, and cooled them with cold water or air. And at the same time, we need to control its diameter range.

- Check for breakdowns through high-voltage detection, If there is a breakdown, the device will issue an alarm and stop production.

- For multi-core sheathed cable, we can add the filling, weaving, aluminum foil, braiding, drain wire, etc. According to different requirements.

- Extruded the sheath, This step is the same as extruding insulation.

- Quality inspection, testing wire diameter, color, tension, deviation, aging, bending, etc. The detection methods for cables and wires with different performances are also different. For example, network cables require a Fluke test, coaxial cables require an impedance test, etc.

What wire harness and cable assembly can we produce?

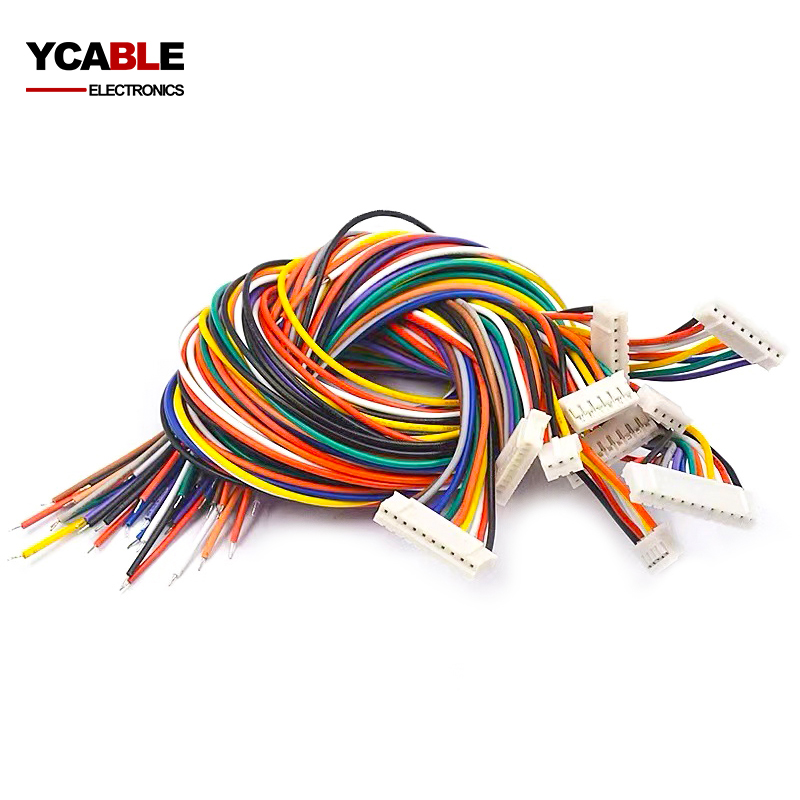

We can customize the wiring harness and cable assembly according to your requirements, we now produce automotive wiring harnesses, patch cords, power cords, over-molded assembly, audio assembly, and water-proof cable assembly.

How to make a wire harness/cable assembly?

- Firstly, we need to evaluate whether we can produce this product.

- If there is a finished product, then we need to draw according to the finished product. If we need to design a new product, we will make a 3D model and draw it according to customer requirements.

- And then we need to formulate the production steps.

- Prepare the materials and start to produce.

- Testing is very important after any step is completed.

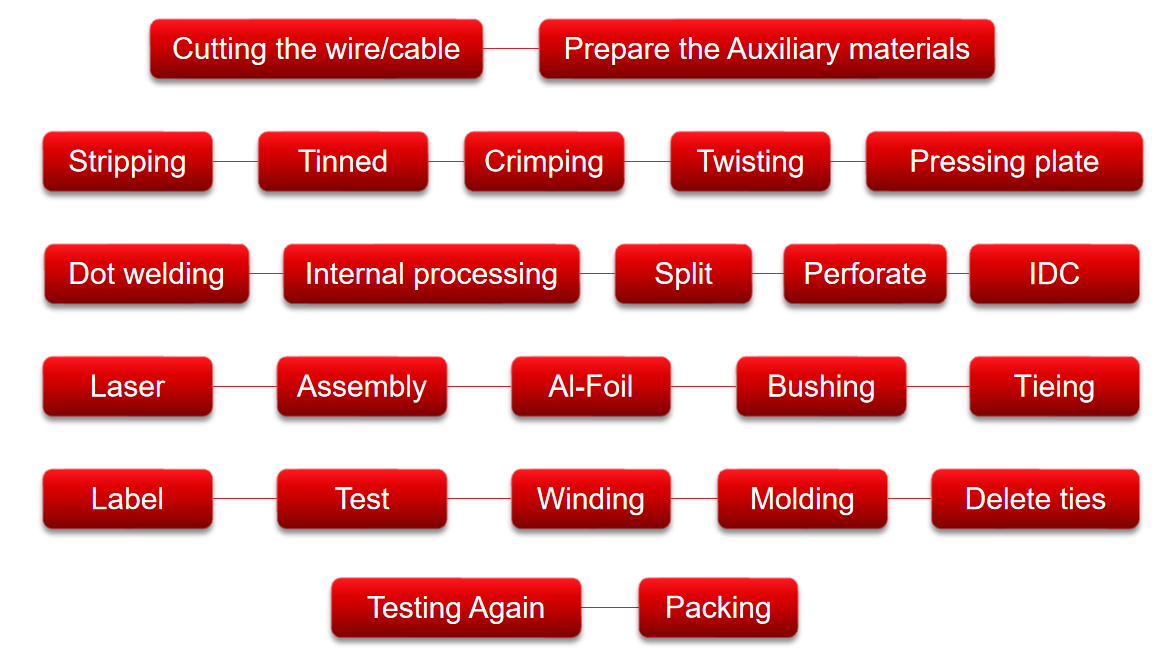

Here are all the basic operation contents: