DT Connector Overmolded Cable Assembly

DT Connector Overmolded Cable Assembly

Item Number:DT Connector Overmolded Cable Assembly

- Model: DT Connector Overmolded Cable Assembly

- Size: Custom

- Color: Custom

- Insulation: PUR/PE/PVC/Custom

- Shield: Custom

- Jacket: PVC/FR-PVC/LSOH/Custom

- Packing: Custom

- OD: Custom

- Conductor Material: Copper, Tinned Copper/Custom

- Drain wire: Custom

Environmental Specifications:

Environmental Space – Non-plenum

Flame Test Method – CMR

Installation Temperature – 0 °C to +60 °C (+32 °F to +140 °F)

Operating Temperature – -20 °C to +60 °C (-4 °F to +140 °F)

General Specifications:

Cable Type

DT Connector Overmolded Cable Assembly

Pairs, quantity

Custom

Cable Component Type

Custom

Conductor Gauge, singles

Custom

Conductor Type, singles

Solid/Stranded

Characteristics:

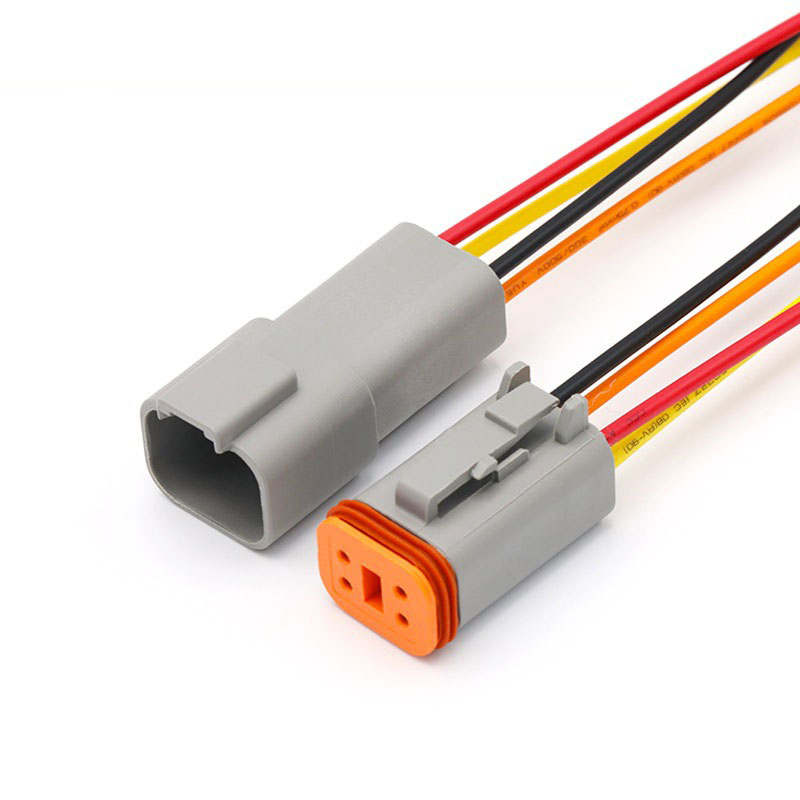

- DT connector cable assembly

DT connector over-molded cable assembly,

Categories

DT Connector Overmolded Cable Assembly

| Electrical Specifications | |

| Name | DT connector cable assembly |

| Cable | Custom |

| Length | Custom |

| Overmold | Custom |

| Color | Custom |

| Pin | custom |

| Operating Voltage, maximum | 20V~600V |

| Standards | VDE CE UL ISO/IEC 9001 |

Description

Insights into DT Connector Cable Assemblies

Essence of DT Connector Cable Assemblies:

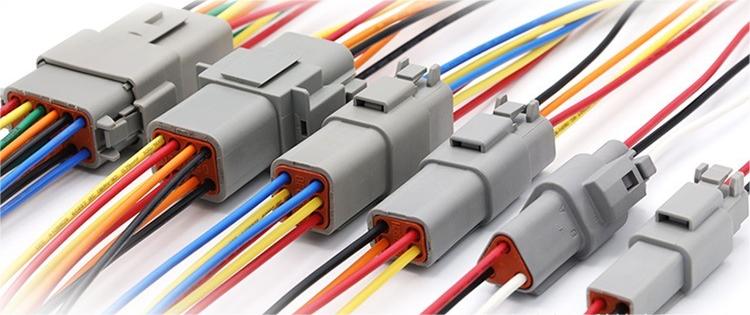

DT connector cable assemblies, crafted by DEUTSCH, are specialized for creating resilient, environmentally sealed connections suitable for linking cables to cables, boards, or devices. These assemblies are pivotal in environments where the slightest compromise in connectivity could lead to significant operational failures.

Deployment Scenarios for DT Connector Cable Assemblies:

These assemblies are perfectly suited for a wide array of applications including Trucks, Buses, Off-road vehicles, Construction machinery, Agricultural tools, Mining equipment, Emergency service vehicles, Forestry gear, Recreational vehicles, Marine crafts, and Motorcycles. Their robustness makes them ideal for challenging conditions.

Optimal Utilization Times for DT Connector Cable Assemblies:

DEUTSCH DT connector cable assemblies are engineered to deliver unmatched reliability and performance, essential for engine or transmission systems, under-hood components, motor controllers, solenoid connections, vehicle frameworks, or cabin configurations. Celebrated for their field-tested durability and strength, these assemblies feature optional flange mounting, diverse pin configurations, cost efficiency, and adaptable designs. They enable the incorporation of numerous size 16 contacts, each with a 13 amp continuous load capability, within a singular compact assembly.

Principal Characteristics of DT Connector Cable Assemblies:

- Accommodate contact size 16 (13 amps)

- Compatible with 14-20 AWG wire gauges

- Configurable into 2, 3, 4, 6, 8, and 12 slot formats

- Offer in-line, flange, or PCB mounting options

- Constructed with a rectangular, thermoplastic shell

- Equipped with an integrated latching mechanism for secure mating

- Feature wedgelocks for assured contact positioning and retention

Temperature Adaptability of DT Connector Cable Assemblies:

Designed to function efficiently across a broad temperature spectrum of -55°C to +125°C, ensuring operational reliability under diverse environmental conditions.

Durability Metrics for DT Connector Cable Assemblies:

Show no electrical or mechanical failures even after 100 cycles of engagement and disengagement, highlighting their robustness.

Insulation Resistance and Environmental Protection Ratings:

- Boast a minimum insulation resistance of 1000 megohms at 25°C.

- Achieve an IP68 rating, indicating superior resistance to water immersion.

- Remain securely locked and intact, withstanding sinusoidal vibration levels of 20 G’s from 10 to 2000 Hz across all axes, with no electrical interruptions exceeding 1 microsecond.

- Demonstrate less than 2 milliamps of current leakage at 1500 volts AC, confirming their dielectric robustness.

Fluid and Moisture Resistance Capabilities:

- Effectively resist damage when exposed to a wide variety of industrial fluids.

- Capable of enduring submersion under three feet of water without compromising electronic functionality or causing leakage, when correctly wired and coupled.

Thermal Cycling Endurance and Material Composition:

- Withstand 20 thermal cycles from -55°C to +125°C without showing signs of cracking, chipping, or leakage.

- The enclosures are made from durable glass-filled PA, grommets from silicone rubber, wedgelocks from glass-filled PBT, and receptacle interfacial seals also utilizing silicone rubber, ensuring the long-term reliability and performance of these assemblies in severe conditions.

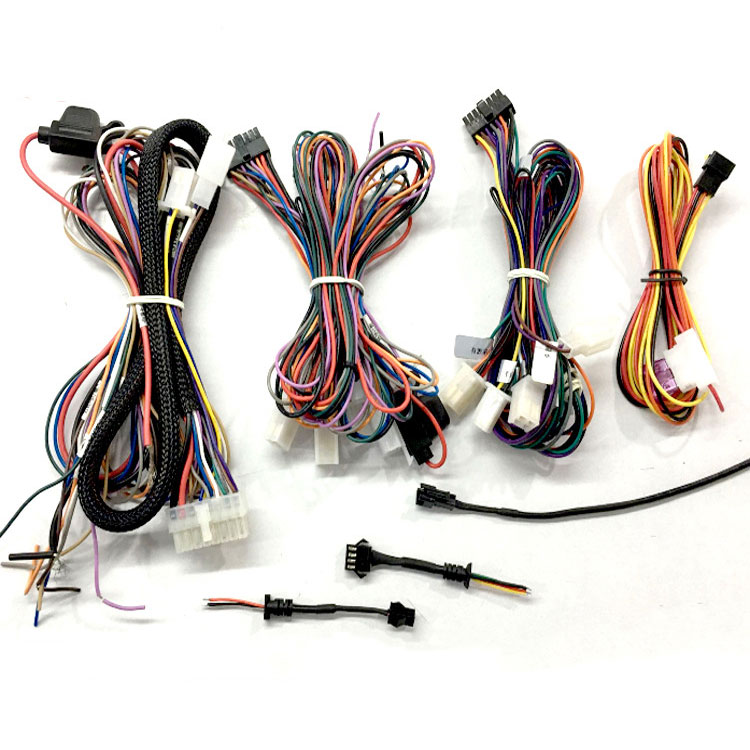

Related Products

M6 Connector Waterproof Cable Assembly

At YCABLE ELECTRONICS, our dedication to excellence in the field of waterproof ...

Custom Overmolded Cable Assemblies

For projects demanding specialized or direct-from-blueprint overmolded cable assemblies, encapsulated circuits, or ...