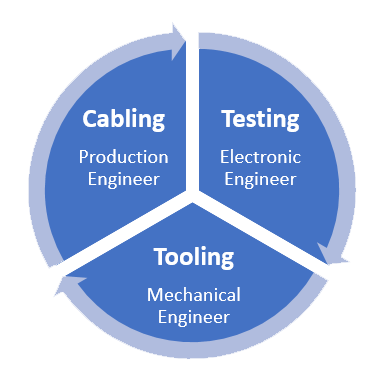

Production Facilities

YCABLE ELECTRONICS can provide you cables, wires, wire harness, and cable assembly. We have our own factory, We are very familiar with the production process of cables and wires, as well as the production and assembly of wire harnesses, We also have comprehensive quality inspection equipment, We have a research and development team and an independent quality inspection department to provide you with the best solution.

Quote Now

Who We Are

From components to FG, every step and every detail,we strictly follow the SOP

set up.

We present herewith our various testing process,equipments and methods to ensure our

commitment.

A-1 Engineering Team

YCABLE is the leader in supplying high-quality, high-temperature wire and cable for harsh environments.

A-2 Reliability Test

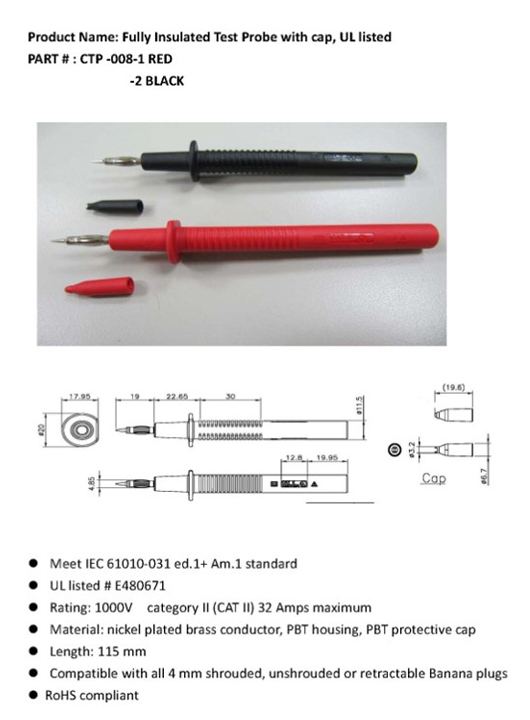

Hi-Pot Tester EXTE CH 7142

Load Current Resistance TPR 6450

CIRRIS 4250

Analyzer CT-8681

Analyzer CT 8751 NAC

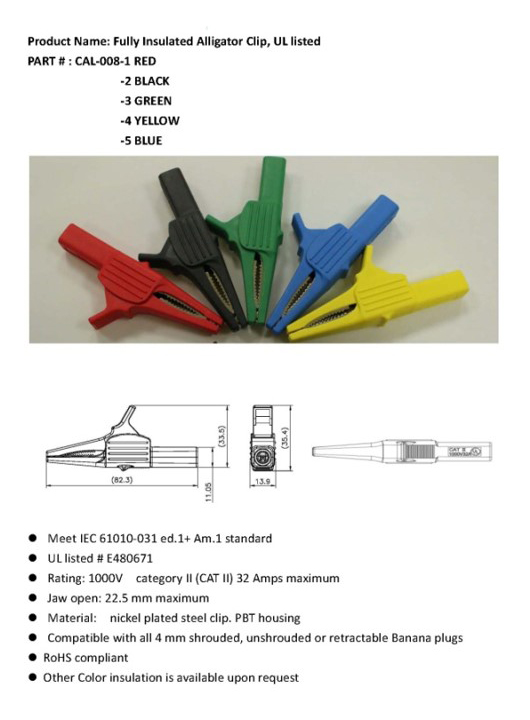

A-2-1 Electric

• Insulation Test

• Current Resistance Test

• CIRRIS Tester

• CT-8681 Tester

• CT-8751 NAC Tester

A-2-2 Mechanical

• Bending Test

• Plug & Pull Force Test

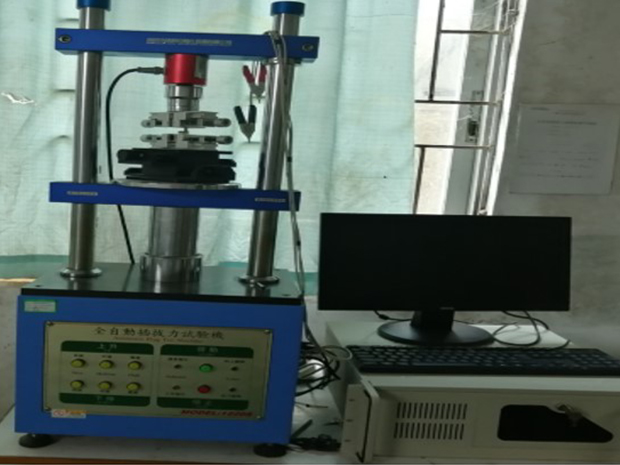

• Plug & Play Test (durability test)

• 360°Rotation Test

• Drop Ball Test

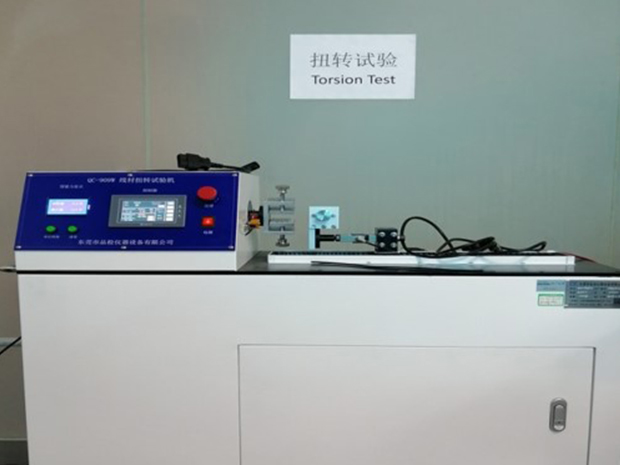

• Torsion Test

• Vehicle Standard Bend Test

• Vehicle Standard Bend Test to SR with 5 Pounds Weight

Torsion Tester

Pull & Insertion Tester

Bending Tester

Plug-in/Plug – Out Force (Durability)

360° Rotation Tester

Drop Ball Tester

Thermal Shock

High Temp Aging Tester

Brine Spray Tester

Ultraviolet Accelerated Aging Tester

A-2-3 Environment

• High & Low Temp Test

• High Temp Aging Test

• Brine Spray Test

• Ultraviolet Accelerated Aging Test

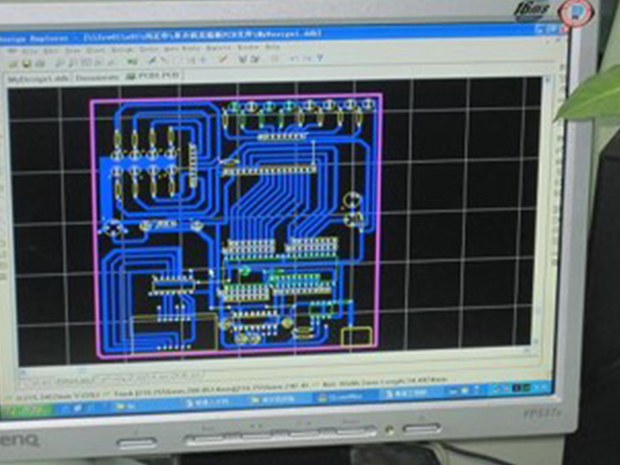

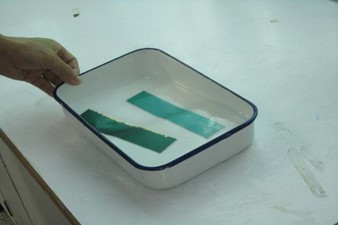

A-3 E-LAB

Drawing

Exposure

Developing

Etching

Drilling

A-3 E-LAB

1. PCB mock up

2. Signal Generator

3. Bridge Test

4. Oscilloscope

5. Frequency Meter

6. Quadratic Element Analysis

Who We Are

From components to FG, every step and every detail,we strictly follow the SOP

set up.

We present herewith our various testing process,equipments and methods to ensure our

commitment.

B-1 Production

YCABLE is the leader in supplying high-quality, high-temperature wire and cable for harsh environments.

Full Automatic Terminal Crimping/Cutting/Soldering Machine

Vertical Injection Machines

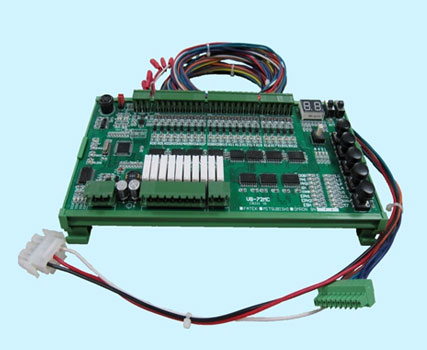

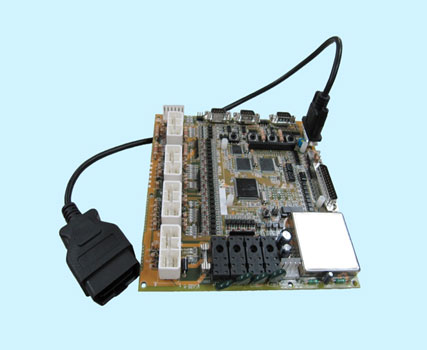

PCBA

Testing

B- 2. Products

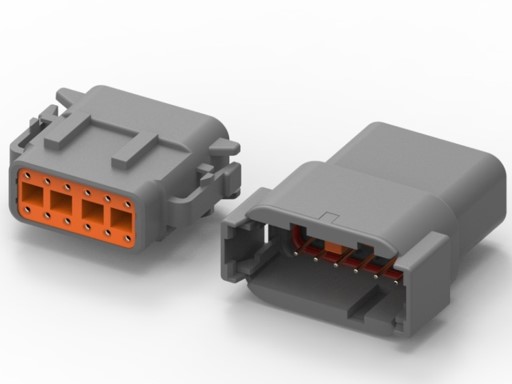

HD 10 series, male and female 6 pin and 9 pins

DTM series, male and female 12 pins Key A, B, C, D

B-2.1Connector series:Equivalent

B-2.1-1:Deutsch

• Waterproof, quick locking connector.

• Reverse contact design to withstand vibration and shock.

• Typical application for heavy duty environment and transportation

industries.

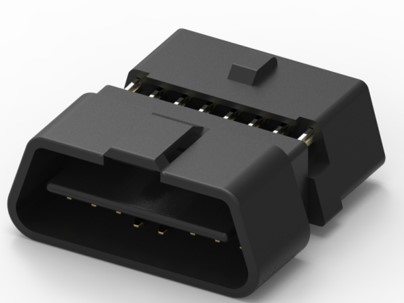

B-2.1Connector series:Equivalent

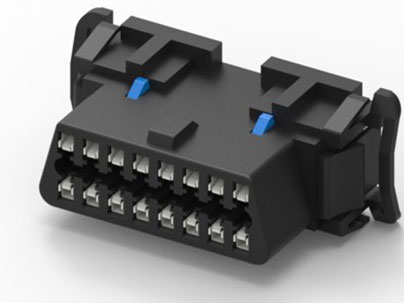

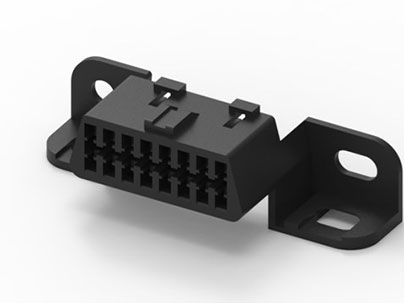

B-2.1-2: OBD II

• On-Board Diagnostics connector

• Each vehicle is necessary

• Standardized interface: 16 pin

• Access to vehicle's computer database

• Monitor emissions condition

• Identify failure problems

B-2.1Connector series:Equivalent

B-2.1-3:Waterproof

• Waterproof M12M) L-Coded

• Waterproof M12(F) L-Coded

• Waterproof M12(M) X-Coded

• Waterproof M12(F) X-Coded

• Waterproof D Size Connector

• Waterproof M12(M) T-Coded

• Waterproof M12(F) T-Coded

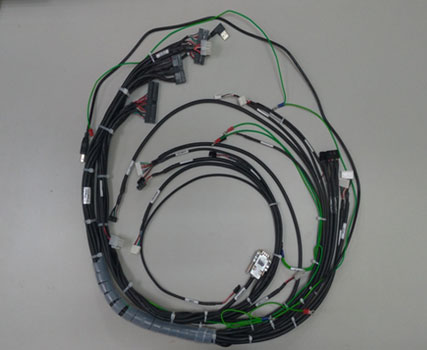

B-2.2. Cable Assemblies and Wire Harnesses

B-2.3. PCBA

B-2.4. Electro-Mechanical Assemblies