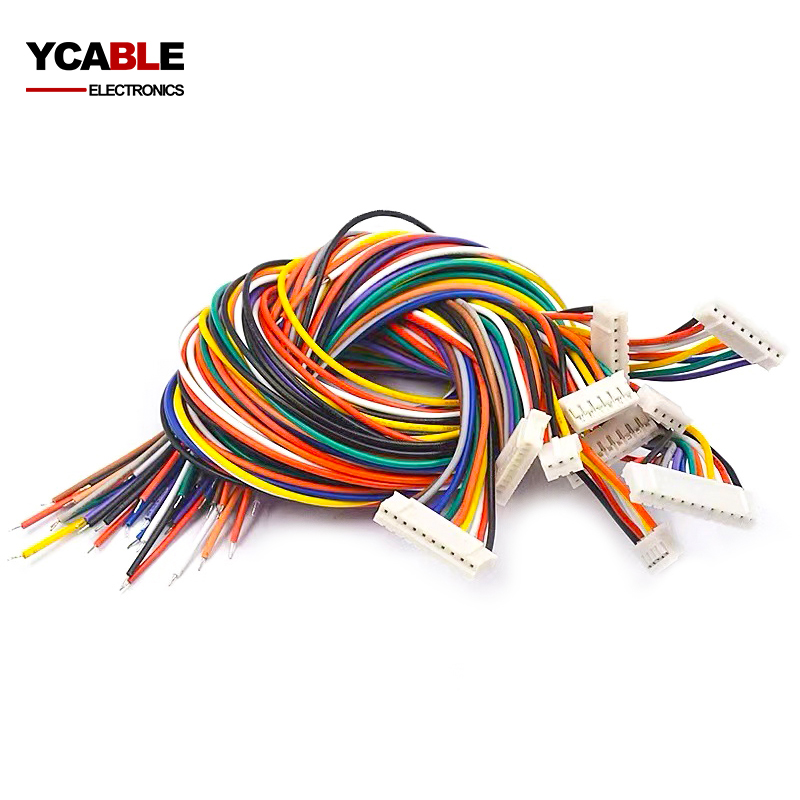

Custom Wire Harness And OEM Cable Assembly Manufactures In China

RCA Audio Cable

Custom RCA Audio Cables Gold-plating 2 male to 2 male RCA cables for amplifier/subwoofer

Custom Solar Panel Extension Cable Assembly

Custom Solar Extension Cable, Select Length, Color, Connector Types

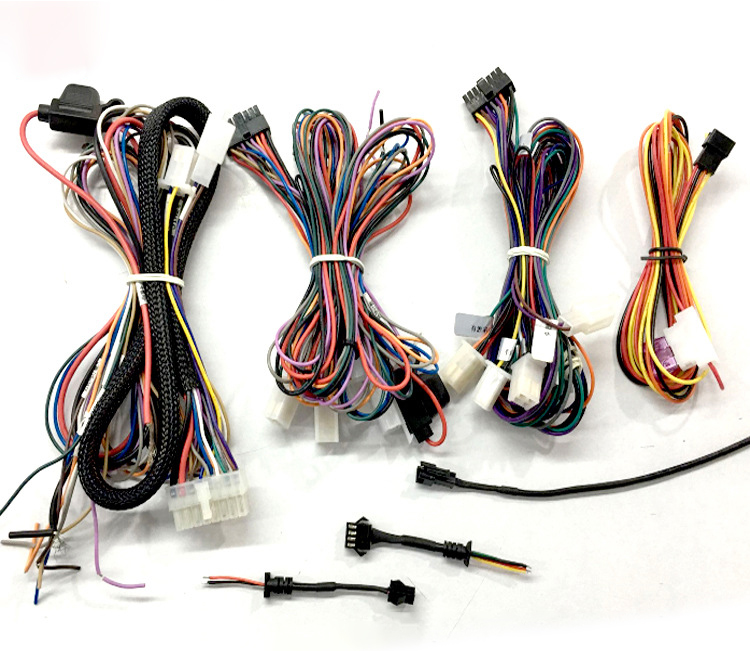

Car Wiring Harness Terminal Wires For Automotive

Car wiring harness terminal wire, also known as wiring harness assembly, can be arbitrar

Who we are?

YCABLE ELECTRONICS company is a professional manufacturer that integrates research and development, design, customization, and production. We support the development and production of small batch wire harness or cable assembly orders. Our main products include automotive diagnostic connectors and wiring harnesses, new energy vehicle car automotive wiring harnesses, industrial equipment wiring harnesses, military wiring harnesses, medical wiring harnesses, and waterproof wiring harnesses. The company has a strong engineering development team, equipped with product structure engineers, electronic engineers, mold engineers, quality engineers, etc. The core members have more than 10 years of work experience and can provide customized solutions for customers. We have a comprehensive production and quality management system, with ISO9001 and IATF 16949 quality systems.

We design and produce according to IPC standards and industry standards, and have advanced production and testing equipment. We adhere to the high quality of each product. The company also has ESD anti-static electronic welding, injection molding, assembly, and testing workshops, producing PCBA wire harnesses, emphasizing product quality and long-term reliability. The company's products are widely sold around the world and have received widespread recognition and trust from domestic and foreign customers! We also look forward to becoming your strategic partner!

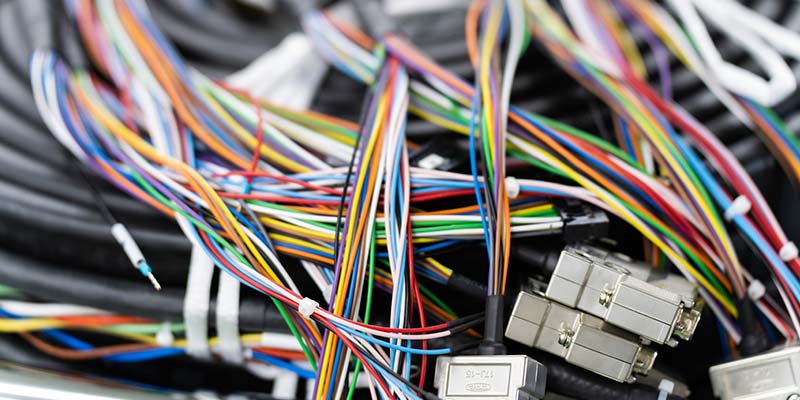

What is a wire harness?

A wiring harness, also known as a wire harness or wire harness manufacturers, is a meticulously orchestrated arrangement of cables encased within an insulating material. Its primary function is to facilitate the transmission of signals or electrical power. These cables are consolidated through the use of straps, cable ties, cable lacing, sleeves, electrical tape, conduit, or a combination thereof. The wire harness streamlines the connection to larger components, seamlessly integrating the wiring into a unified unit, ready for effortless installation.

Enhanced Efficiency: Numerous vehicles necessitate extensive wiring for their operation. The wire harness assembly process significantly streamlines the manufacturing of such vehicles by consolidating all the requisite wires and cables into a single apparatus. Consequently, installation becomes a straightforward "drop-in" procedure, sparing the need to individually route each wire.

Enhanced Security and Safety: The amalgamation of wires and cables within a single harness enhances the security of individual components against the detrimental impacts of vibrations, abrasions, and moisture. Space utilization is optimized, and the risk of electrical shorts is minimized due to the wires being organized into an inflexible bundle. Furthermore, the incorporation of a flame-retardant sleeve reduces the risk of electrical fires when the wires are contained within it.

While professionals may sometimes use the terms "cable assemblies" and "wire harnesses" interchangeably, these multi-wire arrangements can be tailored to serve distinct purposes in diverse environments and applications.

In essence, a wire harness serves as the outer protective sheath for safeguarding an inner conductor or a bundle of conductors. These internal components may already possess insulation and protection sheaths, or they may rely on the wire harness to create an optimal operational environment. In either case, the wire harness offers vital organization at the core of a system, doing so with a straightforward, cost-effective design.

Wiring harnesses are engineered to be both uncomplicated and efficient, which ensures that their costs remain competitive compared to more intricate harnessing solutions. In many instances, a standard wire harness encompasses all the necessary components to optimize various interconnection requirements, making it an ideal choice for a wide array of applications.

What are the wire harness products?

In the realm of wire harnesses, often referred to as wiring harnesses or wire harness assemblies, there exists a diverse array of products catering to several sectors. This guide encapsulates a broad spectrum of wire harness offerings, segmented on the basis of various criteria:

Categorization Based on Usage

- Automotive Wire Assembly: Developed for automotive applications, these wire harnesses play a crucial role in ensuring optimal electrical functionality in vehicles.

- Aerospace Wire Assembly: Constructed to meet exacting aerospace norms, these assemblies are fundamental in the reliable operation of aircraft and related systems.

- Industrial Wire Harness: Built to withstand industrial conditions, these harnesses are vital for the operation and connectivity of equipment in manufacturing domains.

- Consumer Tech Wire Assembly: Customized for gadgets in the consumer electronics market, these harnesses facilitate connection in devices such as smartphones, computers, and household appliances.

- Healthcare Wire Harness: Aligned with rigorous health equipment standards, these harnesses are key in high-precision medical instruments.

Sorting by Wire Harness Configuration

- Solo Wire Harness: A basic single-cable setup, suitable for elementary uses.

- Parallel Wire Harness: Configured with multiple parallel cables for complex, high-current systems.

- 3D Wire Harness: Crafted for spaces with intricate 3D requirements, navigating elaborate configurations effortlessly.

How to test the wire harness?

Wire harness testing is an indispensable aspect, particularly when it comes to verifying correct connections and inspecting for potential damages to the insulation jacket. In the process of Wire Harness Testing, our quality control team adheres stringently to the IPC/WHMA-A-620 Standard. This benchmark is a comprehensive set of visual and quantitative Quality Acceptability Requirements, encompassing aspects like connector application and Cable, Wire, and Harness Assemblies.

Our checklist for evaluating wire harness assemblies includes:

- Precise Labeling: Ensuring each component is correctly identified.

- Insulation and Wire Integrity Check: Looking for any damage to insulation or flaws in wires.

- Continuity Assessment: Verifying the uninterrupted flow of electricity through the harness.

- Wire Gauge Verification: Confirming that the wire thickness matches required specifications.

- Connector and Terminal Suitability: Checking for the appropriate use of connectors and terminals.

How to remove pins from wire hardness

Removing pins from connectors is a delicate task, essential in various industrial applications, especially pertinent for wire harness and custom wire harness manufacturers. This guide provides a structured approach to safely remove pins from both male and female connectors, suitable for professionals and beginners alike.

Preparation for Pin Removal

- Locating the Proper Tool: Identify a small screwdriver that snugly fits into the slot of the pin.

- Tab Identification and Manipulation: Find and gently lift the tab that secures the pin, enabling its removal. If the pin remains stuck, carefully wiggle it free, ensuring not to damage the connector.

Understanding Connector Types

- Male Connectors: These are plug-like pins that insert into female sockets.

- Female Connectors: These contain exposed metal pins for accepting male plugs.

De-Pinning Without Specialized Tools

Male Pin Connectors:

- Utilize needle-nose pliers to grip the base of the pin.

- Apply twisting pressure until the pin dislodges.

- If unsuccessful, carefully slice through the pin's center with wire cutters or a sharp knife, then remove it.

Female Pin Connectors:

- Press down the locking tab using a small screwdriver or paperclip.

- While the tab is depressed, use pliers to pull out the pin.

- If necessary, cut through the center of the pin and then remove it, smoothing any burrs with a file or sandpaper.

General Removal Process

The procedure for extracting pins from both male and female connectors is relatively straightforward. Patience and caution are key to prevent damage to the pins or connectors.

Specific Connector Removal Techniques

Molex Connector:

- Employ a pin extraction tool, inserting it into the connector housing's hole.

- Push and twist the tool to disengage the pin.

- After pin removal, detach the connector from the wire harness.

JST Connector:

- Begin by lifting the top tab of the JST connector.

- Grasp the exposed part of the pin with needle-nose pliers and extract it.

Pin Connector Removal Tool

This specialized tool, equipped with a hook or claw, is designed to release pins from connectors. Some models include a wire-cutting feature for slicing through pins if needed.

Extracting a Broken Pin

Use needle-nose pliers to grasp and twist out a broken pin lodged within the connector. After removal, proceed to extract the remaining pins.

Five Key Tips for De-Pinning Connectors

- Use Appropriate Tools: Selecting the right tools prevents damage and eases the process.

- Exercise Patience: Rushing can cause damage; proceed calmly.

- Gentle Handling: Apply soft pressure to avoid straining the pins or connectors.

- Slow and Steady Removal: Remove pins carefully to avoid bending.

- Maintain Pin Order: Keeping track of the pin order is crucial for accurate reassembly.

What is a cable assembly?

Cable assemblies, often known as cable harnesses or wiring looms, are collections of cables organized into a single entity for specific functions. These assemblies in the realm of cable assembly and custom cable assembly manufacturing are crucial for efficient and streamlined installations.

Characteristics of Cable Assemblies

Organized Cabling: Cables are meticulously grouped by required length and orientation, facilitating simpler and faster installation.

Variety in Composition: These assemblies might encompass diverse cable types, varying in size, color, and length to suit the intended application.

Bundling and Protection: Cables may be encased in sleeves, taped, or secured with cable ties, not only grouping them together but also providing protection and compactness for space efficiency.

Customized Termination Options: Depending on their usage, assemblies can be equipped with a range of terminations, such as plug or socket configurations.

Application in Mass Production

Cable assemblies are instrumental in mass-produced machinery or equipment, notably streamlining the assembly process, especially when identical configurations are required repeatedly. A prime example is their widespread application in the automotive industry, where they ensure consistency and speed in production lines.

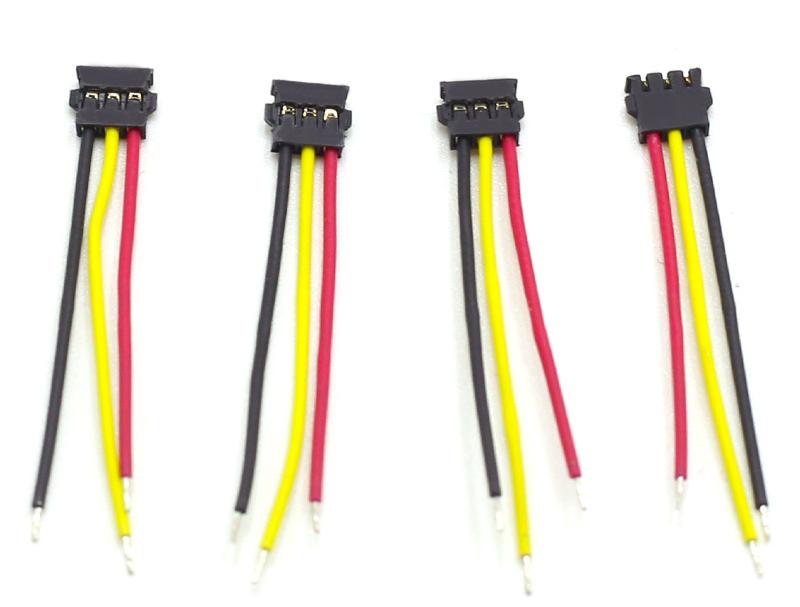

Cable assembly classification

According to cable type:

- -Data cable assembly: such as Ethernet cable assembly, fiber optic cable assembly, etc;

- -Power cable cord assembly: such as copper cables, aluminum cables, etc;

- -Control cable assembly: such as control cables, communication cables, etc;

- -Fiber optic cable assembly: such as single mode fiber, multimode fiber, etc;

- -High frequency cable assembly: such as RF cables, microwave cables, etc.

Based on connector type:

- -Threaded connectors cable assembly: such as M12 connectors, RJ45 connectors, etc;

- -Plug in connectors cable assembly: such as FPC connectors, FFC connectors, etc;

- -Crimp connectors cable assembly: such as IDC connectors, board to board connectors, etc.

According to the purpose:

- -Computers and communication equipment cable assembly: such as servers, routers, switches, etc;

- -Industrial automation equipment cable assembly: such as robots, sensors, actuators, etc;

- -Automotive electronics cable assembly: such as in car entertainment systems, navigation systems, driving assistance systems, etc;

- -Medical equipment cable assembly: such as ECG monitor, ultrasonic diagnostic apparatus, Medical imaging equipment, etc;

- -Aerospace cable assembly: such as airplanes, satellites, rockets, etc

Custom Wire Harness Solutions by YCABLE ELECTRONICS

YCABLE ELECTRONICS, a prominent name among custom wire harness manufacturers, excels in fabricating bespoke wire harnesses designed to endure demanding conditions and meet specific criteria. Our Value Engineering division commits itself to sourcing ideal solutions for diverse applications, concentrating on crafting dependable, economically viable custom wire harnesses that precisely match your requirements.

Manufacturing Processes

- Crimping

- Cutting

- Coiling

- Connecting

- Sub-assembly integration

- Marking

- Soldering

- Stripping

- Terminal application

- Ultrasonic wire welding

We cater to an extensive array of wire harness necessities, presenting choices in harness attributes, connector varieties, coverings, insulation types, and wire and cable dimensions.

Custom Wiring Harness Services

Our service portfolio includes integrating distinct colors in wire harnesses to streamline training and hasten installation and maintenance procedures. Furthermore, we offer the option of embedding logos or text into overmolds on the harness, reinforcing your brand identity or providing user guidance.

We specialize in offering custom branded cables adorned with your company name or logo, alongside tailored cable coding and labeling. Our material selection includes numerous specialized substances to confront environmental challenges or avert corrosion. Manufacturing automation, encompassing stripping, crimping, labeling, and tie-wrapping, is a key strategy to reduce production timelines and enhance quality control.

Dependability and Quality

Every manufacturing phase is meticulously recorded in our advanced ERP system, ensuring consistent quality across repeat builds. We rigorously monitor each step and operator, implementing multiple testing stages within the manufacturing cycle. Additionally, every finished product undergoes comprehensive testing based on our clients' specifications and requirements.

Our facilities boast ISO-9001:2015 certification, reflecting our commitment to superior manufacturing practices.

Cost-Effective Value Engineering

We offer wire harness production both in Canada and internationally, balancing design work in Canada with manufacturing abroad to minimize development and manufacturing expenses. Our approach is tailored to your specific needs, maintaining a flexible platform to accommodate various demands.

We are adept at managing both high-volume production and storage for timely shipment, as well as executing smaller initial runs with the option for numerous repeat builds. Our adaptability extends to accommodating different production mixes and volumes as per our clients' evolving business needs.

Our state-of-the-art ERP system enables us to replicate identical wire harnesses across multiple facilities, enhancing turnaround times and reducing shipping costs. Our team of engineers and designers is ready to work from your blueprints or assist in developing visually appealing wire harnesses that minimize training and installation time.

We collaborate closely with our customers to generate comprehensive documentation, ensuring reliability and consistency in future builds. Individual quality reports for each production batch are also available upon request.

YCABLE ELECTRONICS: Custom Cable Assembly

YCABLE ELECTRONICS, recognized among the elite in cable assembly manufacturing, specializes in delivering both basic and intricate wire harness assemblies and cable fabrication in the USA and China. Our repertoire spans from elementary ground wires to elaborate, multi-terminated custom wire harnesses and custom cable assemblies, each uniquely crafted to meet the diverse specifications of our clients across various industries.

Diverse Wire and Custom Cable Assembly Manufacturing for All Industries

Founded in 1985, YCABLE ELECTRONICS has honed its focus on bespoke wire and cable fabrication. We're steadfast in our mission to pioneer the development of custom cables, wires, connectors, and allied electronic products. Our strength lies in blending manufacturing prowess with innovative solutions, sales strategies, and a robust marketing system, backed by cutting-edge manufacturing equipment and comprehensive product testing facilities. Over three decades of growth and innovation, our wire and cable products have gained a global footprint.

Ensuring Excellence in Wire and Cable Assembly Manufacturing

Our Fremont, California facility has been a hub for producing a diverse mix of low-volume yet high-variety wire and cable assemblies. To address your larger-scale needs, our manufacturing unit in China is well-equipped to handle high-volume orders. We meticulously source cables and components based on your specific drawings or BOMs. YCABLE ELECTRONICS also offers a range of cable testing services to assure the quality and precision of your custom cable products, with each product undergoing stringent testing in our factory. We strive to be your indispensable connection in the realm of cable assembly.

Overview

YCABLE, A global engineering partner for wires, cables, wire harnesses, and cable assembly. From components to FG, in every step and every detail we strictly follow the SOP setup. We will present you with our various testing processes, equipment, and methods to ensure our commitment.

YCABLE hopes to create real and long-lasting value for every customer, becoming the most influential and respected manufacturer in the world. YCABLE firmly believes that details determine success, strictly demands ourselves, and conscientiously completes every product. Responsible for products, Responsible for customers, and Responsible for ourselves. YCABLE will use years of production and research experience to provide a complete solution for cables, wires, wire harnesses, and cable assemblies. If you have any questions or anything you want to know, please feel free and do not hesitate to get contact with us! So Click here, Send us your inquiry, and We will reply to you immediately!

Application

YCABLE can offer you cables, wires, wire harnesses, and cable assembly in many different fields.

In the field of new energy

Nowadays, new energy projects are very popular, New energy electric vehicles, and new energy battery vehicles, We provide automotive wires, car wiring harnesses, car internal cable assembly, charging station wiring harnesses, etc

In the traditional automotive field

we provide automotive lighting wiring harnesses, automotive internal sensor cable assembly, motor wiring harnesses, waterproof cable wire harnesses, etc.

In the field of network communication

we provide RF coaxial cables, ethernet patch cords, RJ45 Lan cables, RJ11 telephone cables, and optical fiber cable assemblies.

In the field of audio systems

we can produce RCA cables, microphone cables, XLR cables, Audio cable assembly, amplifier wiring kits, HDMI cables, speaker cables, guitar cables, speaker power cables, etc.

In the field of electronic wiring harnesses

The components of a regular wire harness are terminals, plastic parts, and electrical wires, The composition of complex wiring harnesses also needs to be added: ties, sleeves, labels, tape, protective sleeves, etc.

In the field of the power cable assembly

we can offer you many kinds of power cords with various national standards.

power cables, and various power cord sockets.

If you have any questions about our cables, wires, wire harness, or cable assembly products, if you are looking for a quotation, or if you want to know about us, contact us at 18767116451 or send us an email at vance@ycable-electronics.com.

Options

YCABLE, A global engineering partner for wires, cables, wire harnesses, and cable assembly. From components to FG, in every step and every detail we strictly follow the SOP setup. We will present you with our various testing processes, equipment, and methods to ensure our commitment.

- Contact us now. Get to know more about our company and our products,

- Contact us now. Find a high-quality and low-priced product that suits you and obtain a quote.

- Contact us now. You will receive our one-on-one service and receive more discounts for first-time orders.

- Contact us at 18767116451, email: vance@ycable-electronics.com