Custom Automotive Wiring Harness Manufacturers in China

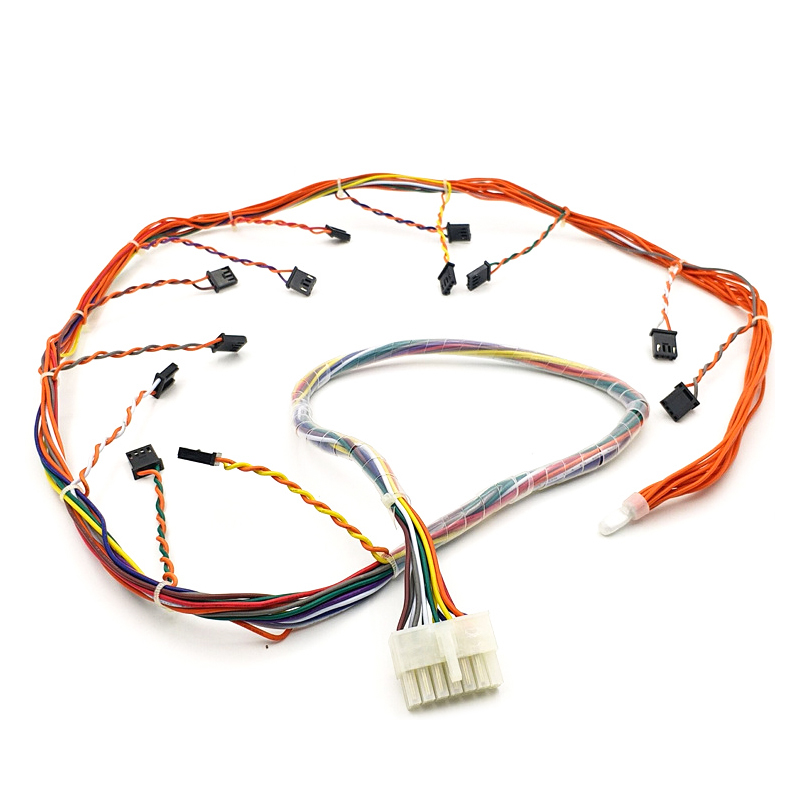

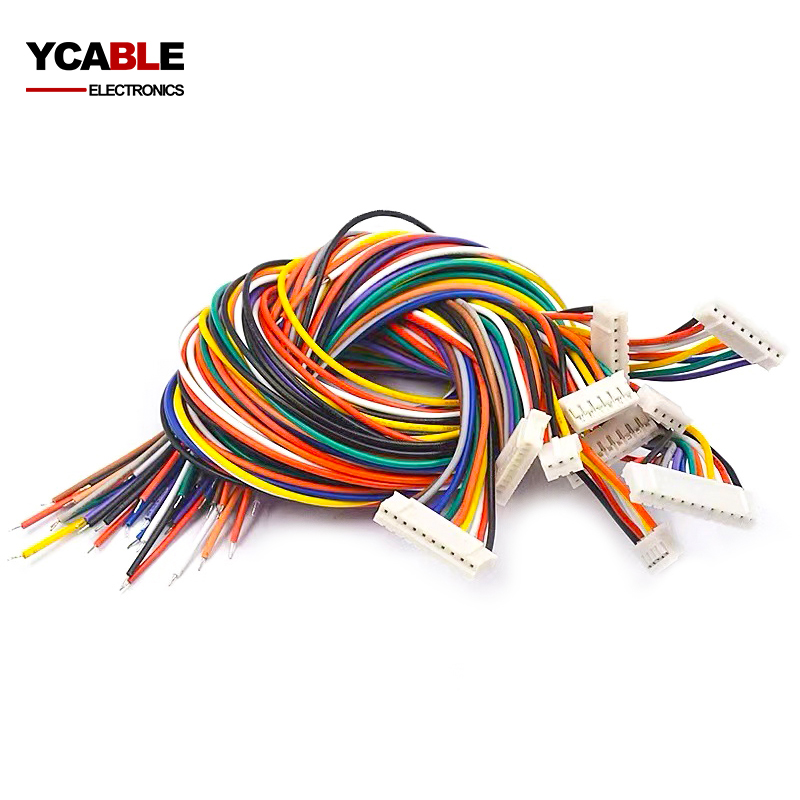

YCABLE ELECTRONICS, hailing from the heart of China's technological forefront. This esteemed entity among automotive wiring harness manufacturers champions the art of creating bespoke vehicular circulatory systems, meticulously catering to the nuanced demands of modern mobility. We excel in sculpting custom automotive wiring harness solutions, ensuring each harness is not merely a product but a pivotal part of the vehicular anatomy that stands robust against the trials of function and time.

Design method of automotive wiring harness system

Certainly, allow me to indulge you with an exposition on the intricacies of crafting a vehicular neural network – or in less florid terms, the design methodology of automobile wiring harness systems.

An Ode to the Vascular System of Vehicular Anatomy

When one muses over the term automotive wiring harness, images of a meticulously arranged medley of wires, connectors, and terminals ensconced within the bowels of our mechanical steeds come to mind. A well-designed harness is the linchpin of a vehicle's electrical system, akin to the nerves and synapses of the human form, conveying impulses and ensuring the veritable symphony of components hum in concert.

Blueprinting the Nervous System

Designing such a system demands a keen eye for detail and a penchant for precision. Automotive wiring harness manufacturers have honed this into a fine art. The process initiates with a schematic – a grand design, if you will – detailing the electrical requirements of the automotive leviathan.

1. The Drafting Table: A Symphony's Score

Like a maestro's score, the schematic lays out the routes for power and signals, ensuring that each wire is accounted for – from the ignition to the most inconspicuous of sensors.

2. The Selection of Prodigies: Choosing the Right Proteges

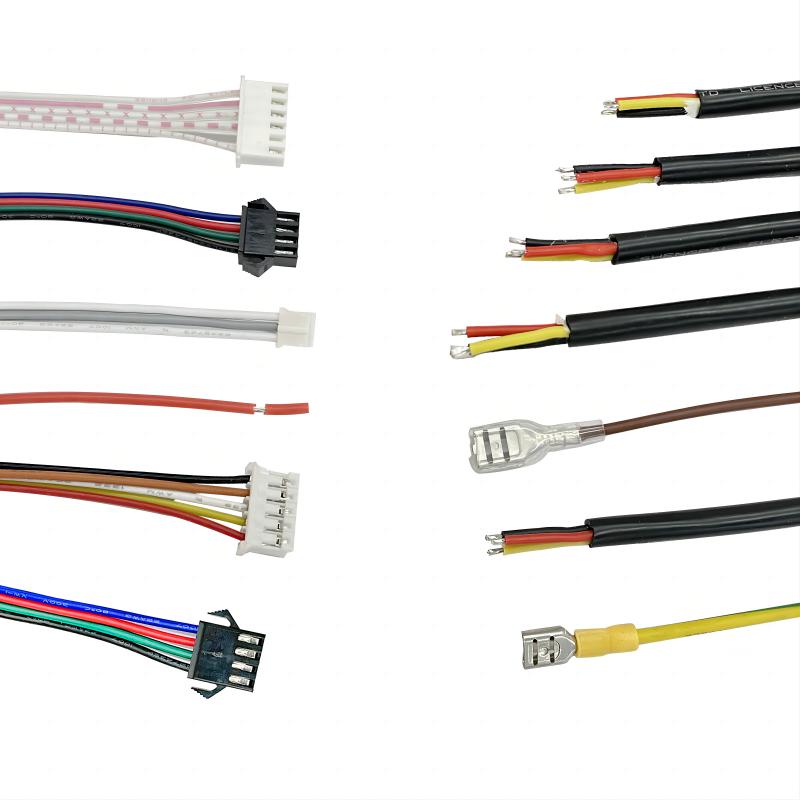

Not all wires are created equal. The choice is paramount. Gauge, insulation material, and durability against the automotive environment's caprices are crucial decisions.

3. The Ensemble: Connector and Terminal Selection

Just as a violinist's bow must complement the strings, so must connectors and terminals befit their wires. High-quality connectors reduce the risk of electrical gremlins playing foul tunes.

4. The Composition: Layout and Prototyping

With components selected, the layout begins. Here, custom automotive wiring harness designers showcase their worth, conjuring a loom that balances electrical efficacy with spatial economy. A prototype emerges, a tangible whisper of the concept.

Trial by Trial: The Rigorous Auditions

Testing is the crucible in which the mettle of the automotive wiring harness is proven. Electromagnetic compatibility, durability, and the ability to weather thermal extremes – all scrutinized to ensure reliability. Only the finest harnesses dance through this ballet of trials unscathed.

From Sheets to Streets: The Manufacturing Crescendo

Upon the benediction of rigorous testing, the custom automotive wiring harness is ready for production. Manufacturing is no less an art, blending automation with the deft touch of skilled artisans. Each harness is a bespoke creation, tailored to its host vehicle with the utmost care.

The Concerto of Installation

Installation is the final act, where the harness is threaded into the chassis. It's a delicate operation, marrying the harness to the vehicle's myriad components with surgical precision.

Encore! The Continual Pursuit of Perfection

In conclusion, the design methodology of automobile wiring harness systems is an iterative ballet. It necessitates a harmonious blend of technical acumen and bespoke craftsmanship. Automotive wiring harness manufacturers who master this symphony ensure their place at the pinnacle of vehicular excellence.

Automotive wiring harness EMC design

The Prelude to Harmony in the Electromagnetic Orchestra

In the grand concert hall of automotive design, automotive wiring harness manufacturers don their finest lab coats and brandish their instruments - not violins or trumpets, but CAD tools and EMC simulation software, to compose a piece that's both functional and resistant to the cacophony of electromagnetic noise.

The Composition of EMC Design

The key to EMC design is not in the crescendo, but in the subtleties of silence between the notes – the elimination of electronic noise that could cause the automotive wiring harness to hum out of tune.

1. The Conductor’s Baton: Shielding and Grounding

Like a conductor with a baton, shielding guides the electrical currents where they must go and keeps them from straying into undesired paths. Grounding, its partner, ensures there's no unwanted solo performance by any electrical component.

2. The Orchestra's Layout: Wire Routing

The paths which the wires of a custom automotive wiring harness take are plotted with the precision of a classical music score, ensuring minimal cross-talk or interference – the dreaded static between radio stations.

3. The Arrangement: Component Selection and Placement

Each resistor, capacitor, and inductor is selected with the utmost scrutiny – much like choosing the perfect oboe or cello for a woodwind or string section. Their placement is a strategic decision that affects the overall harmony of the system.

4. The Rehearsals: Prototyping and Testing

Just as a symphony undergoes rehearsals, so too does an automotive wiring harness. Prototyping and iterative testing are akin to dress rehearsals, ensuring each section of the harness performs impeccably under a variety of electromagnetic influences.

The Ensemble: Integrated Approach

The automotive wiring harness is not a solo act; it's part of a grand ensemble. Its design is integrated with the entire vehicle's architecture, requiring a holistic view to maintain EMC compliance throughout. Every component from headlight to tailpipe must be considered to prevent the automotive equivalent of feedback and distortion.

The Finale: Compliance and Certification

Once the custom automotive wiring harness has been finetuned to perfection, it must pass the rigorous standards set forth by regulatory bodies. EMC compliance is non-negotiable, akin to the final standing ovation for a flawless performance.

Encore: Ongoing Innovation

Automotive wiring harness manufacturers do not rest on their laurels post-certification. The pursuit of EMC perfection is ongoing, much like the eternal quest for the perfect melody. Innovations in materials, design techniques, and testing methodologies are the encores that keep the audience – in this case, the automotive industry – always wanting more.

Case analysis of vehicle car wiring harness failure resolution

Case Study: The Curious Incident of the Flickering Headlights

Once upon a not-so-distant timeline, a case landed on the diagnostic desks of a venerable establishment known among circles as a paragon of automotive wiring harness manufacturers. The subject? A sedan of reputable make, with its headlights flickering like a morse code message from the beyond.

Act I: The Symptom

In the dimming light of dusk, the vehicle in question exhibited a curious case of flickering headlights, an issue not listed in any romanticized motoring adventure but rather in the logbooks of common automotive ailments.

Act II: The Diagnosis

A dedicated team, seasoned in the art of untangling the mysteries of an automotive wiring harness, set out to decipher the riddle. Their tools were not of the mystic sort but rather the practical oscilloscopes, multimeters, and diagnostic scanners.

Act III: The Revelation

Initial suspicion fell upon the usual suspects: a faltering alternator, a rebellious battery, or even a switch with a penchant for theatrics. Yet, these components crooned tunes of innocence under scrutiny. The plot thickened as the diagnosis veered towards the star of our tale, the automotive wiring harness.

The harness, a nexus of vehicular communication, was subjected to a meticulous visual and electrical interrogation. In a twist worthy of a detective novel, the fault lay hidden in the guise of a corroded connector – a mere pawn in the grand game but one with a villainous impact.

Act IV: The Intervention

Resolution beckoned a custom automotive wiring harness solution, one tailored to circumvent the pitfalls of its factory-issued predecessor. Armed with soldering irons and wire strippers, technicians crafted a replacement section of the harness. Each wire was a note in a resurrection symphony, each soldered joint a restorative chord.

Act V: The Denouement

Upon the successful integration of the new harness section, the vehicle’s electrical system was once again put to the test. The headlights, now steady as the gaze of a seasoned sailor, pierced the twilight with unwavering luminosity.

Epilogue: The Reflection

This case underscores a cardinal truth: the integrity of an automotive wiring harness is paramount to the vehicular opus. Even a minor component, when failing, can crescendo into a cacophony of trouble.

Automotive wiring harness manufacturers and technicians orchestrate these complex systems to work in silent harmony, ensuring that every journey, be it mundane or monumental, is not conducted in the erratic flicker of uncertainty but under the reliable glow of innovation and expertise.