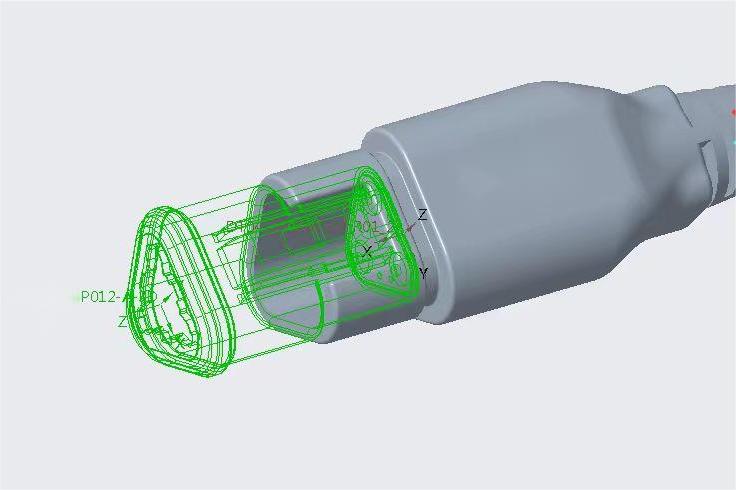

Custom overmolded cable assemblies

What are overmolded cable assemblies?

Overmolded cable assembly refers to an integrated electrical connection device that integrates electrical or mechanical components such as wires, cables, connectors, and insulating hoses through Overmolding technology. The overmolded cable assembly has the characteristics of waterproof, dustproof, acid and alkali resistance, and UV resistance. The overmolded cable assembly can also improve the appearance and mechanical strength of the cable assemblies.

Over molding is a plastic Overmolding process in which two or more materials are used to combine cable assembly, wires, cables and connectors to form an integral component, and the cable assembly is placed in a designated mold. During the molding process, A material substrate will be covered by other materials. The overmolded process requires the use of insert molding (single or multiple Overmolding) to cover the rigid plastic part with a PVC layer or other overmolding material.

How do you make molded cables?

To make a good overmolded cable assembly, the design source needs to focus on the selection of wires, cables and molding materials, a reasonable preload amount in the early stage of over mold design, reasonable differentiation in processing and mold matching, and the production process must be stable. It is certain that a relatively ideal over molded cable assembly product can be made.

The Overmolding cable assembly production process includes several steps such as molding, Overmolding, cooling, demoulding and shearing.

- The first is mold making, that is, making plastic molds according to design drawings and specifications;

- Next, Overmolding is carried out, and the plastic particles are injected into the mold under high temperature and high pressure;

- Then cool it and wait for the successfully injected plastic part to cool and finalize;

- Then demould, and take out the cooled and shaped plastic parts from the mold;

- Finally, cut the cable assembly to the required length.

- It can then be shipped out for sale or further processing.

Overmolded cable assembly development considerations:

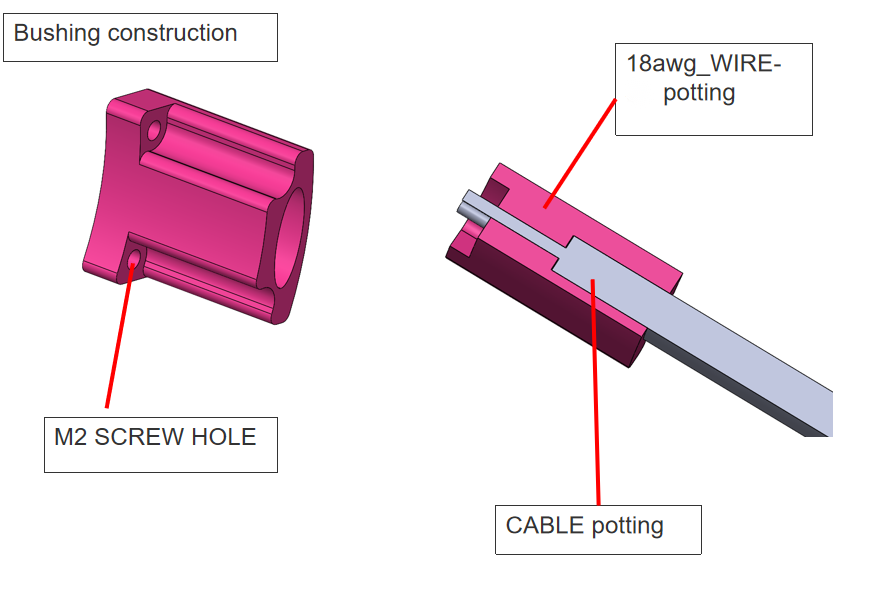

In the early stage of development, the wire skin needs to consider its actual temperature resistance and select a wire with a certain temperature resistance to ensure that during secondary encapsulation, the wire itself must meet the secondary encapsulation temperature resistance requirements;

The selection of secondary coating materials should not only have good adhesion with the wire itself after coating, but also not burn the wire;

When designing products, when encountering the connection between wires and iron or metal parts, the connection fastening method must be considered to prevent the plastic impact force from breaking the connection during secondary encapsulation, causing the product to fail to achieve the actual application effect;

The product design should try to avoid excessively thick glue features to prevent the product from shrinking too much after being coated with glue.

Overmolded cable assembly process precautions:

Before encapsulation, ensure the cleanliness of the wire surface and the actual operation of the front SOP;

In the early stage, when the product can be fully filled, combined with the scientific mold trial method, try to avoid excessive injection speed and injection pressure;

Set a reasonable mold temperature and material temperature to prevent the wire and cable from being burned or deformed;

Stable consistency of manual operations to ensure cycle stability;

After encapsulation, turn around the finished products in a timely manner to prevent the accumulation of wire cable products and the entanglement of products that are difficult to separate.

What is the difference between overmolding and inserts?

1. The processing principles are different: Overmolding is formed by injecting molten plastic into the mold, while inserts is achieved by heating, melting and pressing the materials to be processed to achieve connection or molding.

2. Different scope of application: Overmolding is suitable for manufacturing large quantities of plastic products, such as plastic parts, packaging materials, etc., while butt jointing is more used to make connection structures, such as pipes, cables, etc.

3. Different equipment required: Overmolding requires equipment such as Overmolding machines, molds and cooling systems, while inserts only requires heating equipment and pressure equipment.

4. Different processing characteristics: Overmolding can achieve mass production and can produce complex shapes and sizes; inserts can connect objects of different materials and can be processed in a shorter time.

VS

VS