Best Overmolded Cable Assemblies Manufacturer in China

Exploring the Intricacies of Overmolded Cable Assemblies and Their Creation

Delving into the realm of overmolded cable assemblies reveals a fascinating blend of support, strain relief, and protection - surpassing the conventional backshell or heat shrink methods in typical cable assemblies. This innovative approach integrates these elements seamlessly.

The Art of Overmolding in Cable Assembly: A Detailed Insight

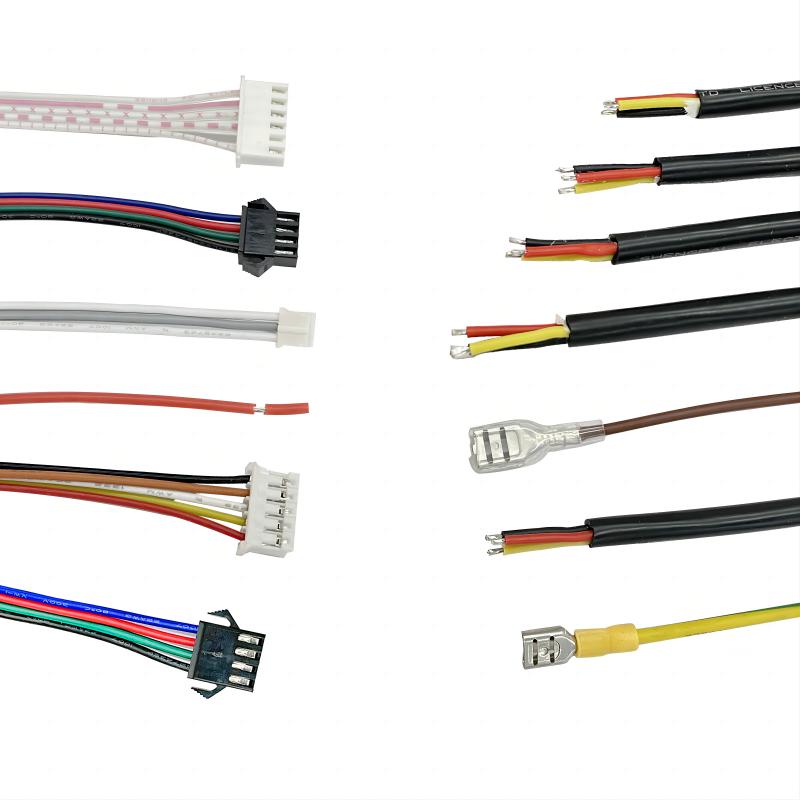

The overmolding process in cable assembly artfully employs molten PVC or other top-notch polymers. This technique envelops the cable assembly, allowing customization in various sizes, materials, shapes, and configurations to align with specific organizational needs. This versatile process is pivotal in fabricating diverse products, including but not limited to:

- Custom overmolded ethernet ptatch cables

- Custom overmolded cable assemblies

- Overmolded medical cable assemblies

- Overmolded telecommunications interconnect

- Over molded power cords

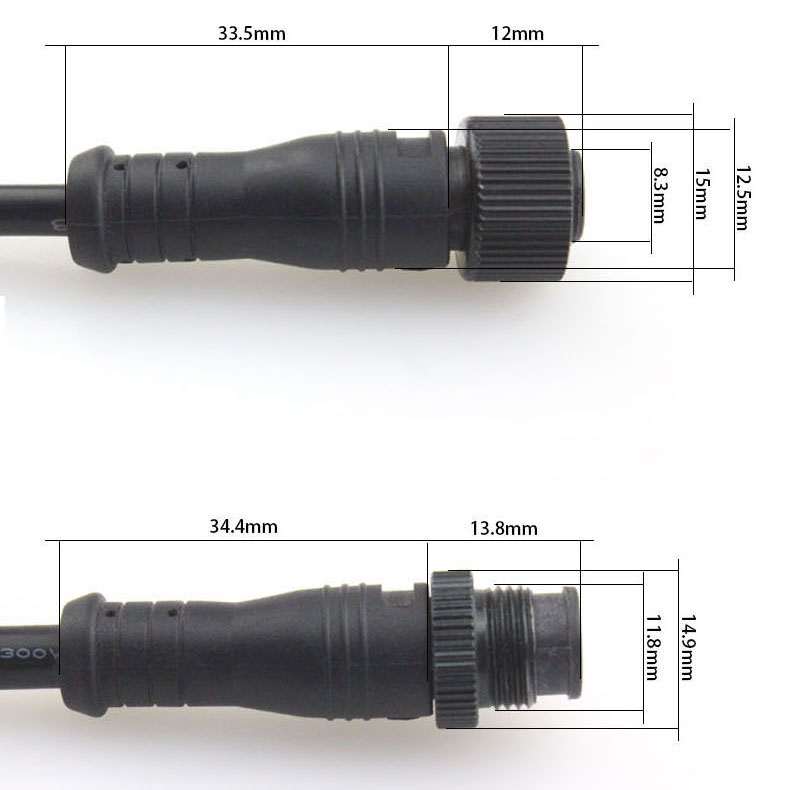

- Over molded waterproof cable assembly

Contrasting Overmolded and Regular Cable Assemblies: A Comparative Analysis

A stark difference marks overmolded cable assemblies from their regular counterparts in construction and material usage. Regular assemblies typically feature a cable with connectors on each end, secured through crimping, soldering, or other methods, often sheathed in protective materials like heat shrink tubing.

In stark contrast, overmolded cable assemblies boast a robust construction. This process involves molding a durable material layer - rubber or plastic - over the cable and connectors, resulting in a unified, resilient unit better shielded against environmental adversaries like moisture, dust, and vibration. Moreover, overmolding lends added strain relief to the cable, minimizing damage from bending or pulling.

Applications and Advantages of Overmolded Cable Assemblies

These assemblies find their place in demanding environments or where reliability is paramount. The overmolding layer enhances the durability of custom cable assemblies, ensuring optimal performance.

YCABLE ELECTRONICS: Where Expertise in Overmolded Cable Assembly Meets Excellence

At YCABLE ELECTRONICS, our expertise lies in crafting environmentally sealed overmolded interconnect cable assemblies for high-reliability systems. Our experience spans military-grade and harsh environmental commercial cable harness fabrication, bolstered by our comprehensive interconnect component design and manufacturing capabilities.

Revolutionizing Cable Assemblies with Overmolding: A Comprehensive Overview

Overmolding has significantly evolved cable assemblies, enhancing functionality through:

- Imperviousness to fluids, enabling exposure to harsher conditions

- Resistance to shock, vibration, and continual flexing without termination point damage

- Aesthetic appeal with corporate logos and trade names incorporated into the overmold

- Waterproof sealing and robust mechanical protection

- Permanent protection of terminations

- Resistance to chemicals and fuels

- Electrical isolation and insulation

- Reduced wear damage

- Flexible routing/cable entry

- Consistent assembly performance

Overmolding Design Considerations: A Critical Perspective

Designing cable assemblies with overmolding necessitates meticulous planning. Engineers must consider the material for the mold, desired appearance, molding material composition, and the molding machine's operating parameters. In many scenarios, a 3D printed overmold model is advisable for form and fit testing before investing in costlier hard tooling.

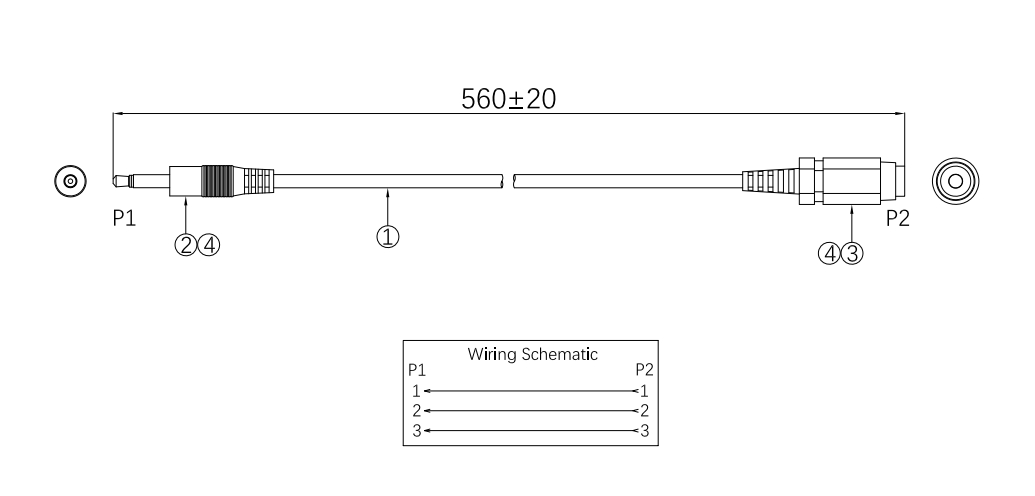

The Process of Overmolding in Cable Assembly: An In-depth Explanation

Overmolding a cable assembly involves high-pressure material injection into a mold cavity. Common materials include thermoplastic or thermoset materials. The process starts with feeding the resin into the heated barrel of the molding machine, mixing with colorants, and then being forced into the mold cavities. Once cooled inside the mold, the material takes on designed features, including logos, trade names, or part numbers.

Material Diversity in Overmolded Cable Assemblies at YCABLE ELECTRONICS

We offer a variety of thermoplastic materials for over-molded cables, including

- PVC,

- TPU,

- rubber,

- Santoprene,

- Polypropylene (PP),

- Polyethylene (PE),

- Polyvinylidene Fluoride (PVDF).

Choosing YCABLE ELECTRONICS for Your Custom Overmolded Cable Assembly Needs

Selecting YCABLE ELECTRONICS for overmolded cable assembly needs brings numerous benefits:

- Superior design customization

- Extensive engineering resources

- Scalable services for large or small orders

- Effective solutions for prototyping cable assemblies, addressing tooling and UL testing costs

- Premium housing features in our standard cable assemblies

In summary, YCABLE ELECTRONICS stands as a leader in overmolded cable assembly, offering unparalleled design, material diversity, and engineering expertise to cater to a wide range of application needs.