Custom Power Cord Manufacturer Molded Power Cables Factory

What is a power cord? vs power cable

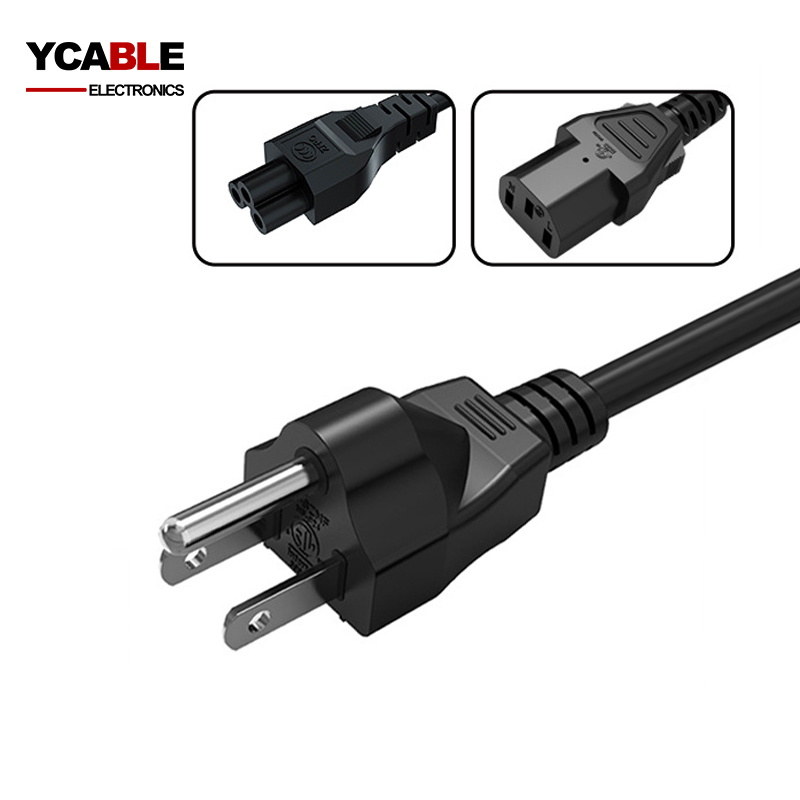

A power cord, from the perspective of a power cords manufacturer, is an essential conduit that bridges an electrical appliance with its energy source. It generally sports a plug at one end for insertion into a wall outlet, and a connector on the opposite end for the device. When discussing power cords, we often mean those flexible lifelines that connect our everyday electronic items to the main electricity supply through a wall socket or an extension unit. Encased within these cords are insulated wires, safeguarded by a robust outer covering.

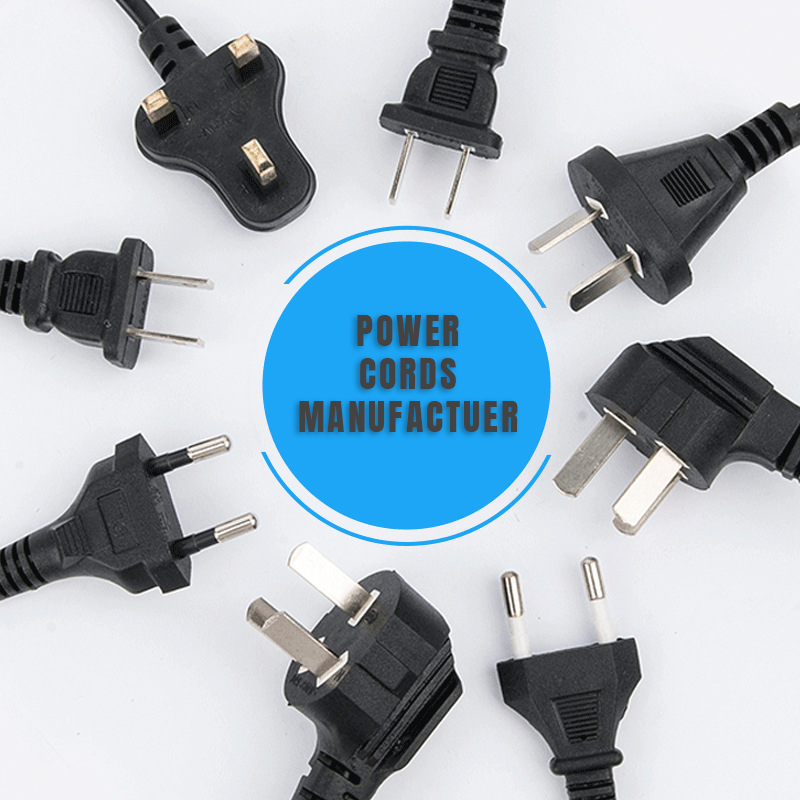

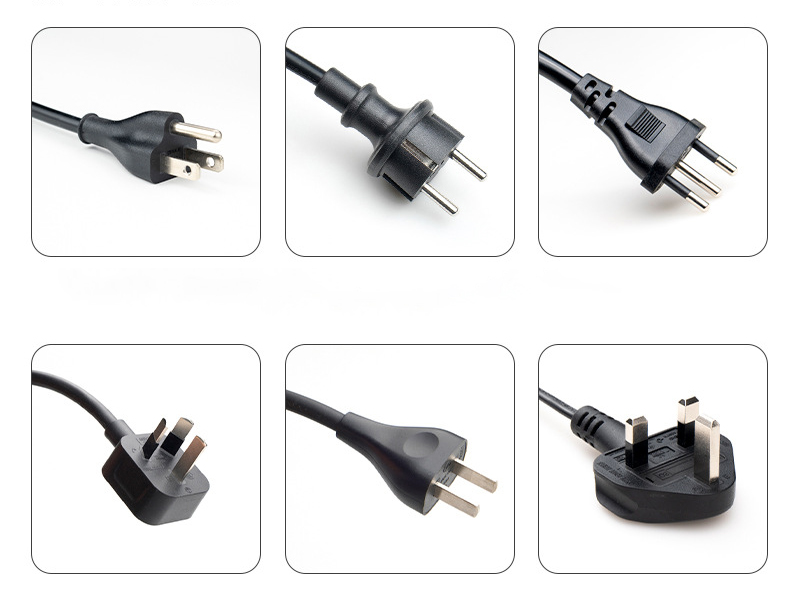

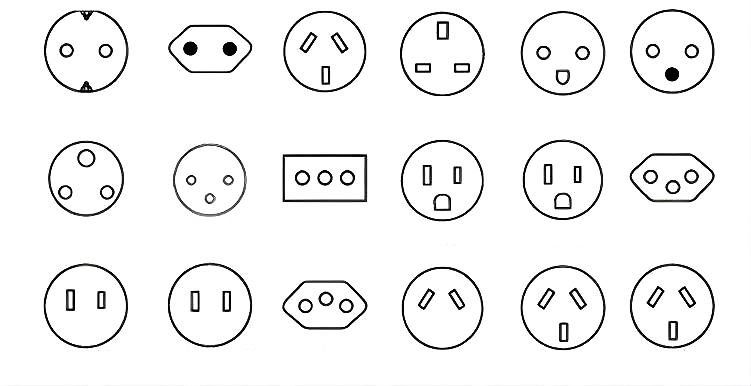

In our day-to-day life, interactions with power cords are frequent as we connect and disconnect a plethora of devices and machines. Designed with user-friendliness and safety in mind, power cords vary in plug configurations, adapting to the diverse electrical standards of different regions around the globe.

Conversely, a power cable, as understood by power cords manufacturers, is a broader term that covers any kind of electrical conduit responsible for power transmission, power cords included. Thus, a power cord falls under the umbrella of power cables. The term "power cable" additionally encompasses the more robust cables employed in industrial or commercial settings for potent power applications, such as the high-voltage cables seen in electrical transmission.

Power cables, in the realm of power cords manufacturers, refer to the heavyweight conductors tasked with the mass movement of electrical energy. These cables house several conductors, each individually insulated and bundled within a protective external layer.

Often laid underground or strung overhead as integral parts of electrical grids, power cables are available in diverse dimensions, forms, and constructs, each tailored for specific roles. Their applications range from transmitting energy over vast expanses to linking substations within an electrical network.

Guide to Selecting the Appropriate Power Cord from a Power Cords Manufacturer

When choosing a power cord, it's essential to first understand your specific power requirements and then identify a cord that aligns with those needs.

Evaluating Manufacturers:

- Research Options: Explore various manufacturers in the market. Customer reviews can be a starting point, but remember, your needs might differ from others.

- OEM Consideration: OEM (Original Equipment Manufacturer) power cords are produced by one entity and sold under another's branding. Investigating both the original maker and the brand is crucial to ensure you're aware of the cord's true origin, as sometimes the manufacturer may differ from the brand on the packaging.

Device Specificity:

- Tailored to Devices: Understand that cords suitable for a computer may not be apt for a medical device. Safety is paramount, and using the wrong cord could damage your device or pose hazards.

- Safety Certification: Reputable cord manufacturers will feature safety certifications like the 'UL' mark, indicating the cord has passed safety and efficiency tests.

Choosing Cord Sets: For various applications, the selection of cord sets varies. Here are some tailored tips:

- For Table Lamps: An 18 gauge, two-prong cord set is suitable for light-duty applications like table lamps. A folding cable system can be a convenient feature.

- Laptops and General Use: A three-prong, 14 gauge cord set works well for laptops and can also serve general purposes like powering music systems.

- Kitchen Appliances: For high-wattage appliances like toasters (around 1 HP or 750 watts), avoid extension boards if possible. If necessary, opt for a board that can support at least 12 amperes, and keep it away from water sources.

- Hairdryers: Directly connect hairdryers (requiring 15 amps) to the power board, not to an extension cord set.

- Treadmills: While not recommended by manufacturers, if space constraints require, use an extension board designed for treadmills.

- Vacuum Cleaners: Choose a three-prong, 12 gauge cord set for outdoor vacuum cleaners, ideally with a plug locking system. For indoor use, a 16 gauge cord set is suitable.

- Room Heaters: Avoid using extension cords with room heaters; connect them directly to a wall unit.

- Holiday Lights: For lengths over 20 feet, use a 16 gauge cord. For shorter distances, a 14 gauge cord is sufficient.

- Home Entertainment: For TVs, home theater systems, and similar appliances, a three-prong, 14 gauge cord is generally adequate.

It's important to remember that the right power cord not only ensures efficiency but also safety and longevity of your devices. Always consult with a trusted power cords manufacturer or professional if you're unsure about the best option for your specific needs.

Custom power cord manufacturer in China

The process of crafting custom power cords, a specialized domain for power cords manufacturers, encompasses several distinct phases:

Wire-Drawing:

- Initiation with Copper: The procedure initiates with 5-ton coils of 8 mm diameter copper wire rods. The primary objective is to slim down the diameter to 2 mm, augmenting both ductility and electrical conduction.

- Further Refinement: The wire is then meticulously thinned down to meet precise specifications demanded by specific applications.

- Annealing for Flexibility: Post-reduction, the wires undergo a heating process known as annealing, recuperating flexibility and conductivity diminished during the downsizing.

- Stranding into Conductors: Subsequently, the annealed wires are bunched together, forming conductors.

Insulation:

- Extrusion for Protection: Using extrusion methods, the conductors are enveloped in a protective layer to avert electrical leakage. Common insulators include PVC cables, though alternatives like Cross-linked Polyethylene (XLPE) for high-voltage scenarios and Ethylene propylene (EPR) for enhanced durability are also utilized.

- Rigorous Testing: The entirety of the cable undergoes a high-voltage electrical test, ensuring no current escapes.

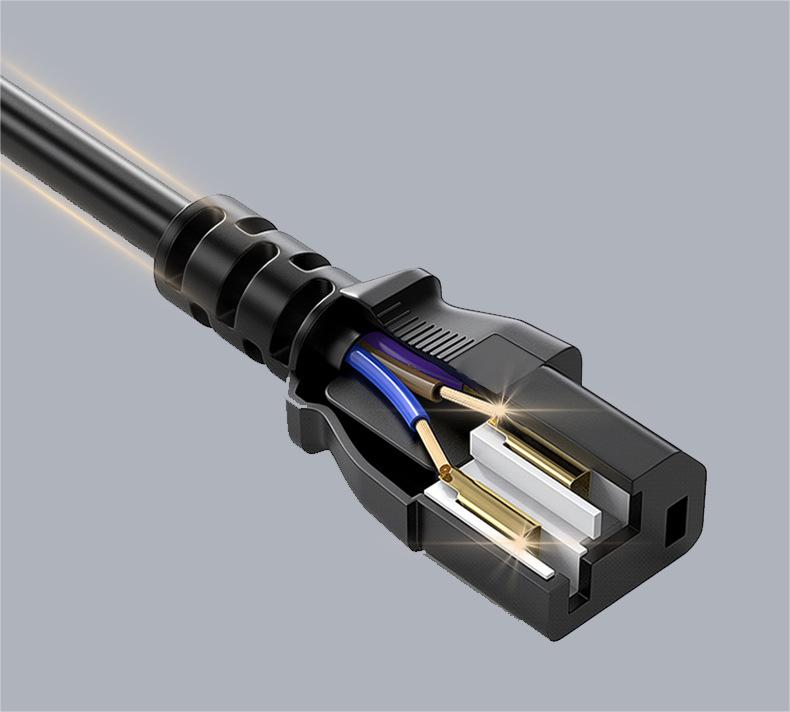

Phase Wiring:

- Creating Multi-Core Cables: The conductors are assembled into a multi-core format, with phases designated by colors or numbers in accordance with industry standards.

- Insulation Verification: Following the wiring, the cable is re-examined to confirm the insulation's effectiveness.

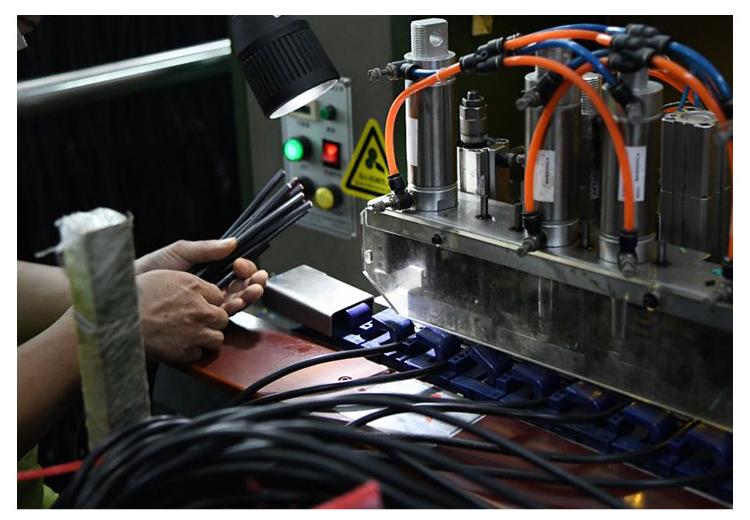

Injection Molding for Plugs:

- Molding Process: In this phase, materials like PVC are melted and shaped into plug forms through injection molding.

- Intensive Quality Checks: The focus here is on the integrity of the plug formation, checking for flaws like cracks, exposed wires, or impurities.

Power Cord Conductivity Assessment:

- Safety Evaluation: This crucial stage involves comprehensive high-voltage, insulation, and polarity testing.

- Consumer Safety Priority: This step is fundamental to ensure the power cords are safe for user interaction, highlighting the commitment of power cords manufacturers to safety and reliability.

Each stage in this process is essential for transforming raw materials into the final, user-ready power cords, exemplifying the meticulous standards upheld by power cords manufacturers in their products. We can custom the color of the power cable, the length of the power cable, and the injection molded shape of plug, also can add your brand and logo on it.

What else you need to know about power cords

Exploring the Extent of Power Cord Lengths: For power cords manufacturers, the utmost stretch of a power cord is influenced by a blend of safety guidelines and functional criteria, in addition to the characteristics of the linked device. Commonly, indoor power cords stretch to about 100-150 feet, whereas outdoor versions span 50-75 feet. Yet, these lengths can fluctuate, tethered to the cord's electrical diameter and current capacity.

Power Cord Selection for Portable Generators: Crucial factors to weigh:

- Connector Suitability: Pinpoint a plug congruent with your generator's socket.

- Current Handling Capability: Seek out a cord adept at conveying the peak current from your portable generator.

- Protective Outer Layer: The cord's external sheath should be apt for outdoor exposure, like the SJTW type.

Power Strip and Extension Cord Dynamics: It is advised against coupling a power strip or surge protector with an extension cord. These units should ideally anchor directly into a wall socket.

Merging Extension Cords with Power Strips: Linking an extension cord to a power strip is doable. Nonetheless, it's pivotal to tally the collective current rating of the apparatuses engaged with the power strip, ensuring it can bear the overall electrical load, thus curtailing risks of overburdening and potential fire hazards.

Outdoor Extension Cord Essentials: For alfresco application, select an extension cord sanctioned for such use. These cords are constructed from robust materials that defy UV degradation and retain pliancy in frigid temperatures. Equally important is opting for a cord that matches the electrical load you intend to utilize, to avert overloading and fire perils. Scour for cords marked with "SJTW" or "STOW", signifying outdoor suitability. Additionally, a cord with an appropriate grounding plug is necessary for electrically grounded apparatuses.

Fire Ratings in Power Cords: Power cords do bear fire resistance ratings, reflecting their ability to withstand fire, heat, or smoke. Amongst power cords manufacturers, prevalent ratings include VW-1 and FT1. There exist other ratings for specialized settings, although these are generally not pertinent to standard power cords.

Contrasting Grounded and Ungrounded Power Cords: A grounded power cord, identifiable by its trio of prongs (neutral, hot, and ground wires), furnishes a secure route for electrical discharge in fault conditions, lessening the likelihood of electric shock or fire. Conversely, an ungrounded power cord, sporting only a pair of prongs (neutral and hot), lacks this safety conduit.

Augmenting Power Cord Length: Yes, the span of a power cord can be amplified using an extension cord. Such cords possess a plug at one end and a receptacle at the opposite, enabling connection to a power source from a further distance. However, it's crucial to acknowledge that employing an extension cord might diminish the safety and efficiency of the device, as the cord's thickness and length may be inadequate for the device's power demands. Power cords manufacturers recommend the use of the briefest possible cord and selecting an extension with a gauge apt for the power requirements of the device.