Best High Temperature Wire Silicone Heating Resistant Teflon Wire Manufacturer

High Temperature Teflon Wire

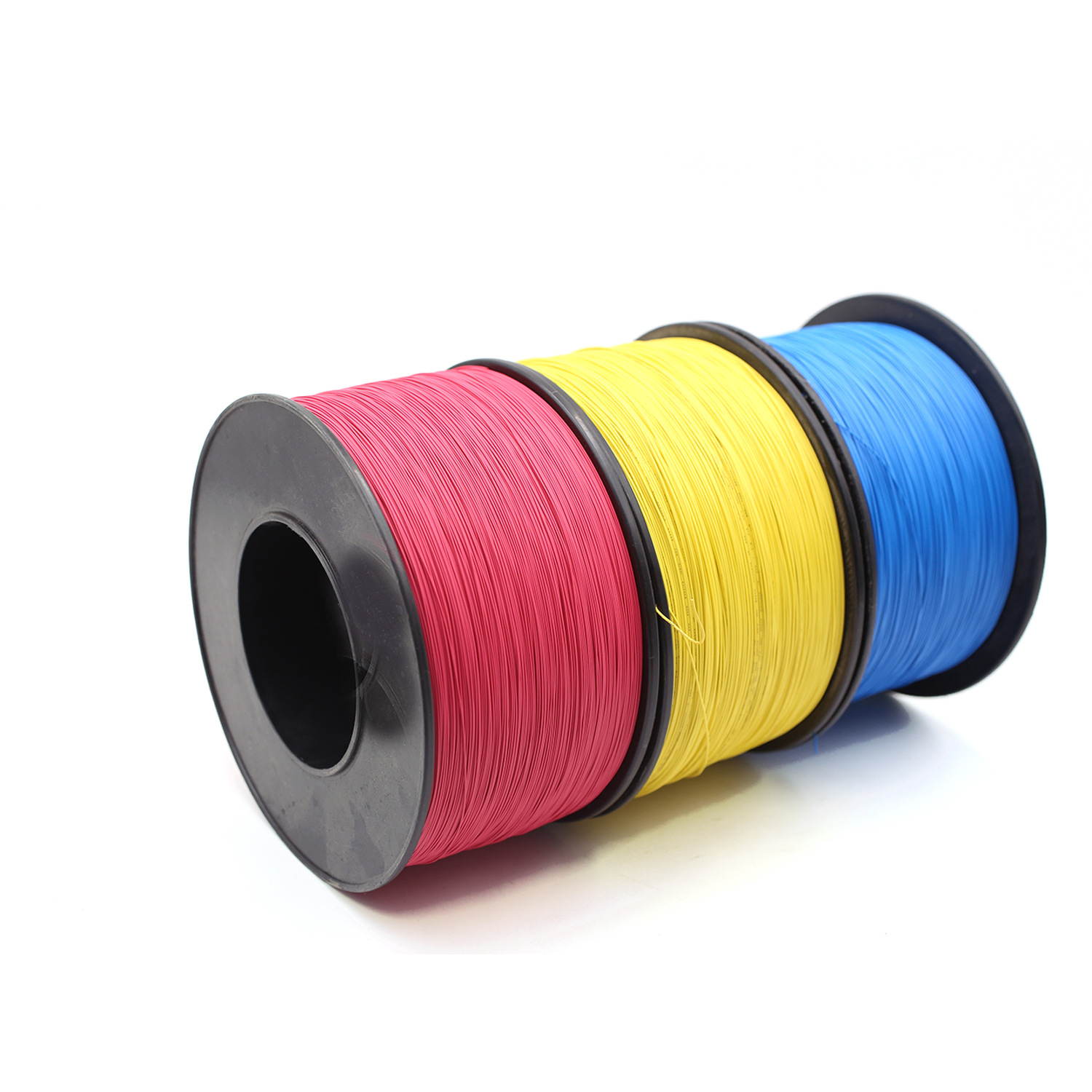

Custom High temperature Teflon coated wire, Teflon wire is an electrical wire that is in

PTFE wire

14 AWG 16 AWG 18 AWG 22 AWG 24 AWG PTFE wire High Temperature Teflon Insulated Hook Up W

FEP wire

18 AWG 20AWG 22 Gauge High Temperature FEP Wire Teflon Insulated Hook Up Wires Manufactu

PFA wire

26 AWG 28 AWG 30 Gauge China PFA Coated Wire Teflon Insulated silver wire manufacturer a

ETFE wire

10 AWG12 AWG 14 Gauge ETFE insulated wire Teflon coated wire high temperature wire manuf

Silicone wire

4 Gauge 6 Gauge 8 AWG 10 AWG 12 AWG 14 Gauge 16 AWG 18 AWG 20 AWG 22 AWG 24AWG 26AWG Bes

Fiberglass silicone wire

16 AWG 18 AWG 20 AWG 22 AWG 24 AWG 26 AWG 28 AWG UL3122 fiberglass braided silicone rubb

Carbon fiber heating wire

1K 3K 6K 12K 24K Carbon Fiber Heating Wire High Temperature Resistance Conductive and Te

Nichrome Silicone Heating Wire

Nickel chromium alloy/Aludirome/Constantan alloy/Concord Manganin/Copper Nickel Alloy Si

What Is High Temperature Wire?

there are many different kinds of high temperature wires and cables, Their common characteristic is that they can be used for a long time in high-temperature environments, They are all made of the heat resistant materials, like TEFLON, silicone, rubber, XLPE and so on, Fluoroplastics(TEFLON) and silicone rubber are the two most commonly used materials for the high temperature wire insulation.

Material Composition

- Conductor: Primarily copper, sometimes enhanced with tinning, silver, or nickel plating for elevated conductivity.

- Insulation: Incorporates Polytetrafluoroethylene (PTFE), PFA, ETFE, MFA, FEP – collectively recognized as Teflon.

Distinctive Attributes

- Heat Endurance: Teflon wires boast the capability to endure temperatures as high as 260°C (500°F), perfect for high-temperature environments.

- Chemical Immunity: Teflon's insulation layers are notably resistant to a wide array of chemicals, solvents, and oils.

- Electric Qualities: Notable for their superb dielectric properties, making them ideal for high-frequency electrical applications.

- Adaptive Flexibility: While inherently stiff, Teflon can be processed to achieve a certain level of flexibility, vital for specific applications.

- Friction Factor: Teflon is known for its exceptionally low friction coefficient, reducing wear during both installation and usage.

Usage Spectrum

- Aerospace: Teflon wire, a prime choice for high temperature wire, is widely used in aircraft wiring for its heat resistance and lightweight properties.

- Electronics: Essential in high-temperature scenarios like soldering operations or in the wiring of internal electronics.

- Chemical Industry: Chosen for scenarios where exposure to harsh chemicals is expected.

- Medical Devices: Utilized in sterilization processes and medical instruments that require endurance to high temperatures.

Sizes and Performance Ratings

- Teflon wires are available in various AWG sizes, accommodating a range of conductor thicknesses.

- Voltage ratings vary, but common specifications include 300V, 600V, and higher for specialized applications.

In essence, when businesses in fields such as aerospace, electronics, chemical processing, or medical equipment manufacturing are in search of a reliable high temperature wire or Teflon wire, these products emerge as superior choices. Manufactured to withstand extreme conditions, these wires assure performance and durability in demanding applications.

High Temperature TEFLON Wire

high temperature teflon coated wire(high temperature heat resistant wire) is a very common high-temperature wire, It was discovered by Roy Plunkett in 1936 when he began researching alternatives to Freon at DuPont in the United States. there are high temperature teflon PTFE silver plated wire, FEP teflon silver plated copper wire, PFA insulated Teflon wire, and ETFE wire. TEFLON coated hook up wire is used inside equipment that can withstand temperatures above 200 degrees Celsius, and can up to 260 degrees, Currently, there are only two types of certification for Teflon wire, one is UL certification and the other is VDE certification.

Fluorinated ethylene propylene insulation stranded tinned copper wire, 200C, 300V/600V, UL1332, UL1330, UL10588, UL1591, UL1901, UL10064,

Polyfluoroalkoxy insulation straned copper wire, 250C, 300V/600V, UL1911, UL10362, UL1726, UL1929, UL1710, UL1882, UL1859

Polytetrafluoroethylene wire, 260C, 300V/600V, UL1180, UL1199, UL1213, UL1570, UL1659, UL1815, UL10393, UL10344, UL1584

Ethylene-tetra-fluoro-ethylene coated wire, 150C, 300V/600V, UL10086, UL1671, UL10316, UL1867, UL1644, UL10584

Teflon Wire Specifications

Constituents of the Wire

- Conductor: Primarily crafted from copper, often enhanced with tinning, silver plating, or nickel plating for improved conductivity.

- Insulation: Predominantly utilizes Polytetrafluoroethylene (PTFE), alongside PFA, ETFE, MFA, FEP, collectively known as Teflon.

Principal Characteristics

- Thermal Tolerance: Teflon wires, quintessential high temperature wires, endure up to 260°C (500°F), ideal for high-heat environments.

Constituents of the Wire

- Conductor: Primarily crafted from copper, often enhanced with tinning, silver plating, or nickel plating for improved conductivity.

- Insulation: Predominantly utilizes Polytetrafluoroethylene (PTFE), alongside PFA, ETFE, MFA, FEP, collectively known as Teflon.

Principal Characteristics

- Thermal Tolerance: Teflon wires, quintessential high temperature wires, endure up to 260°C (500°F), ideal for high-heat environments.

- Resistance to Chemicals: The Teflon coating provides robust defense against a multitude of chemicals, solvents, and oils.

- Electrical Qualities: Teflon wires boast outstanding dielectric properties, making them suitable for high-frequency applications.

- Flexibility: Though inherently rigid, Teflon can be processed for enhanced flexibility, essential for specific uses.

- Friction: Teflon's low friction coefficient means reduced wear during installation and use.

Utility Areas

- Aerospace: Teflon wire, a prime high temperature wire, is extensively used in aircraft wiring due to its thermal resilience and light weight.

- Electronics: Essential in high-heat scenarios like soldering operations or internal electronic wiring.

- Chemical Industry: Ideal for scenarios where wire exposure to aggressive chemicals is probable.

- Medical Equipment: Suitable for sterilization processes and high-temperature medical devices.

- Dimensions and Standards

- Sizes: Available in various AWG sizes, from fine to thick conductors.

- Voltage Ratings: Commonly 300V, 600V, and higher for specialized needs.

Safety Compliance

- Teflon wires adhere to stringent safety and quality protocols, including UL, CSA, and military specifications (MIL-W).

In summary, for B2B entities seeking a dependable high temperature wire or cable, Teflon wire emerges as a versatile, robust choice, apt for diverse sectors like aerospace, electronics, and medical equipment, ensuring efficacy under extreme temperatures and challenging conditions.

High Temperature Silicone Wire

High temperature silicone wire can also withstand temperatures up to 200 degrees Celsius, but compare to the teflon wire, silicone insulated wire is softer than Teflon insulated wire, Silicone wire is more suitable for environments that require repeated bending, But it is not very wear-resistant, so we can add a layer of fiberglass braid on the silicone insulation surface to improve its service life(fiberglass braided silicone wire), Many silicone wires in China are not flame-retardant, but YCABLE ELECTRONIC can provide flame-retardant silicone wires that can be extinguished within 60 seconds under open fire. The general categories of silicone wires include: silicone insulated single core high-temperature wires, silicone insulated braided wires, multi-core silicone sheathed cables, and extra soft silicone wire. UL approval silicone wire: UL3135, UL3122. VDE approval silicone wire: H05S-K, H05SJ-K. We also can OEM silicone wires.

![]()

![]()

Silicone Wire Specifications

Material Composition

- Conductor: Predominantly fashioned from tinned copper, renowned for its effective electrical conductivity.

- Insulation: Crafted using silicone rubber, bestowing the wire with its notable flexibility and capacity to resist high temperatures.

Principal Features

- Temperature Endurance: Silicone wires excel in withstanding temperatures ranging from -60°C to 200°C (-76°F to 392°F), categorizing them as high temperature wires.

- Adaptability: A prominent trait of silicone wire is its pliability, particularly in colder environments, making it ideal for use in areas requiring tight bends.

- Resistance to Elements: Exhibiting commendable resilience to water, ozone, and various chemicals, though it's important to note its chemical resistance may not parallel that of Teflon.

- UV Durability: Silicone is also adept at resisting UV exposure, rendering it suitable for outdoor uses.

- Electrical Stability: Offers consistent electrical properties across a broad temperature spectrum.

Utilization

- Household Appliances: Employed in devices like ovens and coffee makers where heat resistance is imperative.

- Lighting Solutions: Especially in high-temperature lighting settings.

- Motor Applications: Valued for its flexibility and heat resistance in motor windings.

- Transformers and Power Units: Particularly in those operating at higher temperatures.

- Automotive Uses: Applied in engine compartments and other areas facing extreme heat and cold.

Variety in Sizes and Ratings

- Silicone wires come in a wide array of AWG sizes, suitable for both power and signaling roles.

- Voltage ratings are diverse, typical ones being 300V and 600V, with specialized variants offering different ratings.

Compliance with Safety Norms

- Silicone wires generally conform to safety and quality benchmarks established by UL (Underwriters Laboratories) and CSA (Canadian Standards Association), with other regional and application-specific standards also being pertinent.

In summary, for sectors necessitating robust, high temperature wires, silicone wires present themselves as a formidable option. Their flexibility, temperature resilience, and adaptability across various applications make them a choice worth considering for businesses focused on quality and reliability in high-demand environments.

High Temperature Heating Wire

High temp heating wire will generate heat after being energized, there are also different kinds of the heating wires, There are PVC insulation spiral core heating wire, silicone rubber heating wire, silicone rubber braid heating wire, silicone rubber carbon fiber heating wire, TEFLON insulation carbon fiber heating wire, and T-Type carbon fiber heating wire. Suitable for jade mattresses, cushions, physiotherapy mattresses, floor heating industry, microwave oven, hair dryer, cooking utensils, heating equipment, warm air blower, electric blankets, air conditioners, bath heater, automobile paint baking room, and another drying machine.

![]()

![]()

High Temperature Heating Wire Overview

Definition

A high temperature heating wire is designed to produce heat through electrical resistance when an electric current passes through it. The wire's composition allows it to endure and operate efficiently at elevated temperatures without deteriorating or melting.

Types of High Temperature Heating Wires

- Nickel Chromium Alloy Heating Wire

- Made from an alloy of nickel and chromium, commonly referred to as Nichrome.

- Offers high resistance, making it suitable for producing heat.

- Resistant to oxidation and doesn't easily form hot spots.

- Constantan Wire Heating Wire

- An alloy primarily made of copper and nickel.

- Used less frequently than nichrome but offers specific resistive properties that can be beneficial in certain applications.

- Carbon Fiber Heating Wire

- Made from carbon fibers that offer resistive properties.

- Extremely flexible and lightweight.

- Suitable for applications where a more uniform heat distribution is required.

Insulation Materials

Given the elevated operating temperatures of these wires, they are often insulated using high-temperature resistant materials to ensure safety and durability.

- Silicone: Offers flexibility and decent temperature resistance.

- PVC: Commonly used for general purposes but has a lower temperature threshold compared to silicone or Teflon.

- Teflon (FEP): Provides exceptional heat resistance and electrical insulation properties.

Applications

High temperature heating wires are used across various industries and applications:

- Industrial Ovens and Furnaces: For controlled and uniform heating.

- Heated Hoses and Tracing: To prevent fluids from solidifying in cold environments.

- Electronic Devices: For localized heating or deicing.

- Medical Equipment: For sterilization and other heat-based processes.

- Automotive: In applications such as heated seats and mirrors.

- Home Appliances: Such as toasters, hair dryers, and space heaters.

Safety and Regulation

Due to the inherent risks of electricity and heat, high temperature heating wires must adhere to strict safety standards and regulations. This can include:

- Overheat protection mechanisms.

- Grounding and shielding to prevent electrical hazards.

- Adherence to regional and international safety standards and certifications.

High Temperature Thermocouple Wire

The compensating wire for the thermocouple is used to extend the thermode and make up the thermocouple measurement system by connection with indicating instrument.

Definition

A thermocouple is a temperature-sensing element that converts temperature changes into a small voltage. The high temperature thermocouple wire is used to create this element and is formed by joining two dissimilar metals. The generated voltage is proportionate to the temperature difference between the measurement point and the other end, which is often kept at a reference temperature.

Types of Thermocouple Wires Based on Metal Composition

Different metals/alloys provide varying measurement ranges and accuracies:

- Type K (Chromel-Alumel)

- One of the most commonly used thermocouples.

- Suitable for a range of -200°C to +1260°C (-328°F to +2300°F).

- Type J (Iron-Constantan)

- Useful in vacuum, oxidizing, reducing, and inert atmospheres.

- Range of 0°C to +750°C (32°F to +1382°F).

- Type T (Copper-Constantan)

- Suitable for low temperature applications.

- Range of -200°C to +350°C (-328°F to +662°F).

- Type N (Nicrosil-Nisil)

- Offers stability at high temperatures.

- Range of -200°C to +1300°C (-328°F to +2372°F).

- Type S, R, and B

- Made of noble metals (platinum-rhodium combinations).

- Suitable for very high temperature measurements up to 1700°C (3092°F).

Insulation Materials

Given their use in high-temperature environments, thermocouple wires are insulated with materials that can withstand such conditions:

- Teflon: Offers exceptional heat resistance and dielectric properties.

- PVC: Used for general-purpose applications with moderate temperature requirements.

- Silicone: Provides flexibility and can endure higher temperatures compared to PVC.

- Mica: Ideal for extremely high-temperature environments, often combined with other materials.

- Ceramic: Used in some of the most extreme high-temperature applications.