Battery Cable Extension 4 Gauge Battery Cable Assembly Manufacturer

Transparent Battery Cable

YCABLE ELECTRONICS stands as your artisanal source for a broad spectrum of battery cable

What is battery cable?

Battery cables, essential in automotive electrical systems, are composed of a rigid, single-conductor wire typically made from heavy gauge copper. Commonly insulated with PVC or XLPE, these cables play a crucial role in safely connecting electrical automotive parts to the vehicle's battery.

Components and Features of Battery Cables

- Material and Insulation: Heavy gauge copper is the primary material, chosen for its excellent electrical conductivity, and is typically shielded with PVC or XLPE insulation.

- Battery Leads: These cables include both a positive lead, which connects to the ignition system, and a negative lead for grounding to the vehicle’s chassis. They are commonly rated for up to 60 volts.

- Environmental Resistance: The outer jacket of the cable, both insulated and flame-retardant, safeguards the internal wiring against various environmental threats like salt, fuel, oil, water, lubricants, and acid. These cables are also capable of enduring moderately high temperatures.

- Versatile Usage: Apart from automotive applications, battery cables are also employed in marine settings and various industrial contexts.

Battery Cable Connection in Vehicles

- Positive and Negative Cables: Vehicles typically have two main battery cables - a positive one (usually red) and a negative one (generally black). The positive cable connects the positive terminal of the battery to the starter motor, while the negative cable links the negative terminal to a grounding point.

- Cable Size: Due to their function in transmitting significant energy, battery cables are substantially larger than standard domestic cables.

Types and Selection of Automotive Battery Cables

- Variants: The market offers diverse types of automotive battery cables, including SGR, SGX, and SGT, utilized for connecting battery terminals to the starter or grounding points in numerous vehicles.

- Choosing the Right Cable: Selecting an appropriate battery cable is dependent on the specific needs of the project and the environmental conditions. It's crucial to match the cable size to your electrical system's demands, as a cable that is too small can overheat and become a safety hazard.

- Considerations for Size: The choice of battery cable should be based on the required amperage and the cable's length to ensure safety and efficiency.

What is battery cable assembly?

Features of Battery Cable Assemblies

- Versatile Termination: These assemblies can be terminated with various electrical connectors and boots, tailored to suit a wide range of applications.

- Length Range: Typically, their lengths vary from twelve inches to forty-eight inches, accommodating different spatial requirements.

- Gauge Variety: YCABLE ELECTRONICS produces battery cable assemblies in common gauges from 4AWG to 4/0AWG, catering to a broad spectrum of power needs.

Durability in Harsh Conditions

High-quality battery cable assemblies are essential for systems operating in harsh environments, like marine settings, where they are subjected to vibration, moisture, corrosion, and more. YCABLE ELECTRONICS focuses on building assemblies that can withstand these extreme conditions, prioritizing longevity and durability.

Customization and Manufacturing Capabilities

As a contract manufacturer for OEMs globally, YCABLE ELECTRONICS offers:

- Gauge Options: Manufacturing capabilities range from 26 to 3/0 gauge, suitable for various power applications.

- Conductor Variations: Options for single and multi-conductor battery cables.

- Diverse Styles: A selection of stranding and jacket styles.

- Termination Flexibility: Offerings include single or double-ended terminals with various sizes and styles.

- Enhanced Protection: Utilizing heat shrink with adhesive and lug soldering for additional durability.

- Terminal Enhancements: Molded terminal caps installation for improved safety and performance.

- Identification and Quality Assurance: Label identification for easy tracking and state-of-the-art crimping technology with validation of crimp pull-out force to ensure quality and reliability.

YCABLE ELECTRONICS' commitment to producing resilient and customized battery cable assemblies positions them as a leader in meeting diverse electrical system requirements across various industries.

Battery cable Specification

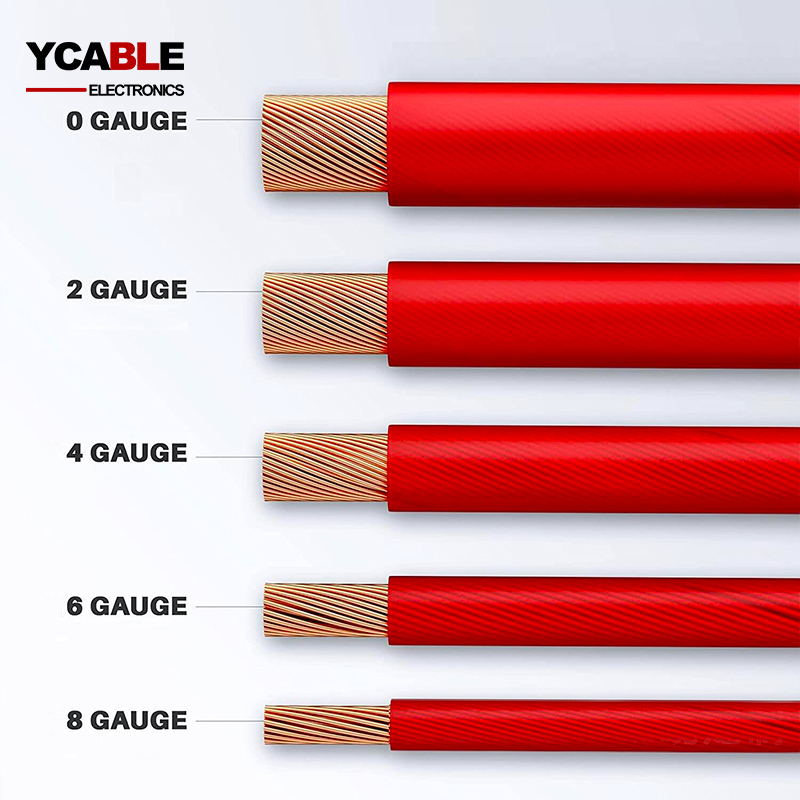

Battery Cable Gauge

- Heavy-Duty (2/0 battery cable, 1/0 battery cable, 1-4 Gauge battery cable): For applications that demand high current, such as industrial machinery and automotive power systems.

- Light-Duty (6-8 Gauge battery cable): Ideal for general electronics and smaller engines.

Battery Cable Material

- OFC (Oxygen-Free Copper) battery cable: High conductivity, resistant to corrosion.

- CCA (Copper Clad Aluminum) battery cable: Lightweight and cost-effective, though less conductive than OFC.

Battery Cable Insulation

- PVC (Polyvinyl Chloride) battery cable: Commonly used, resistant to chemicals and moisture. or transparent PVC, Smoke PVC

- XLPE (Cross-Linked Polyethylene) battery cable: Higher temperature resistance and durability.

- Silicone battery cable

Battery Cable Length

- From short battery jumper cables to extensive battery cable assemblies, length must be suited to your application to minimize loss and maximize efficiency.

Battery Cable Color Coding

- Typically, red is for the positive terminal and black for the negative. However, custom colors can often be specified in bespoke battery cable assemblies.

Battery Cable Connectors and Terminations

- Battery Cable with Clamps: Ideal for jumper cables and temporary connections.

- Battery Cable with Lugs: These are often used for more permanent installations and are bolted in place.

Battery Cable Voltage and Current Ratings

- Ensure the cable meets the requirements for voltage drop and current-carrying capacity based on your application.

Battery Cable Industry Standards

- Look for certifications such as UL, ISO, or SAE to guarantee that your battery cables meet industry norms.

The Custom Route: Battery Cable Assembly Tailored to Your Needs

In specialized fields, off-the-shelf cables might not cut it. This is where custom battery cable assembly comes into play.

Battery cable with lugs

1/0 battery cable with lugs, 2/0 battery cable with lugs, 4/0 battery cable with lugs, 2AWG battery cable with lugs, 0 AWG battery cable with lugs, 0 gauge battery cable with lugs,

The Materials We Use

Lugs

- Copper Lugs: The top-of-the-line choice for those who require high conductivity and resilience against corrosion.

- Aluminum Lugs: A budget-friendly but effective alternative, especially suited for less demanding environments.

Battery Cable

- Oxygen-Free Copper (OFC): The pièce de résistance for applications demanding the highest levels of conductivity.

- Copper Clad Aluminum (CCA): A cost-efficient, lightweight alternative for less stringent requirements.

Insulation

- PVC: Robust and resistant to a variety of environmental conditions.

- Rubber: Flexible and adept at withstanding mechanical stress.

Types of Battery Cables with Lugs We Offer

- Ring Type Lugs: Ideal for permanent, secure installations, often used in marine and industrial settings.

- Fork Type Lugs: Designed for quick installations and removals, commonly used in automotive applications.

- Pin Type Lugs: Used in specialty applications where pin-receiving terminals are utilized.

Custom Battery Cable Assemblies

- Integrated Solutions: We can incorporate battery cables with lugs into larger battery cable assemblies for specialized applications.

- Application-Specific Designs: Tailoring for environments such as high-temperature conditions, extreme weather, or corrosive atmospheres.

Special Features

- Color-Coded Lugs: For easy identification during installation.

- Heat-Shrink Tubing: For added insulation and protection.

- Tin-Plated Lugs: For additional corrosion resistance.

Custom battery cable assembly manufacturer

Custom Battery Cable Assembly: Precision-Engineered for Superior Performance Our custom-made battery cables are crafted to provide exceptional performance, featuring pure copper conductors and durable copper connectors, such as ring terminal cable lugs and top post style battery terminals. We offer an extensive selection of sizes and configurations for these cables, allowing you to tailor them to your precise needs on our website.

Our custom battery cables are designed to be bigger and better, tailored to your specific requirements using top-quality GXL, GPT, or marine cable. Recognizing that a robust battery cable can significantly enhance a car's startup, especially in harsh conditions or when the starter or battery is underperforming, we craft our cables to be thicker and heavier for improved durability and efficacy.

Premium Components for Exceptional Quality

- Advanced Cable Construction: We custom-make our cables to the desired length, ensuring they are more substantial and durable than standard options.

- High-Quality Connectors and Terminals: Our commitment to excellence is evident in our choice of high-quality tin-plated clad copper battery terminals, complemented by anti-corrosion bolts. We offer both standard quality lugs and electroplated heavy-duty lugs, specifically chosen for their low resistance and ability to endure high temperatures without melting, unlike cheaper lead alternatives.

Durable and Protective Finishing

- Robust Waterproof Sealing: Post-crimping, we meticulously seal the cable ends with thick-walled, adhesive-lined heat shrink tubing. This adhesive resembles hot glue in its properties, effectively filling any gaps and creating a waterproof barrier. This sealing process is key in insulating the cables and protecting them from corrosion.

At YCABLE ELECTRONICS, as a manufacturer specializing in custom battery cable assembly, we focus on delivering products that excel in both reliability and quality. Whether for automotive use, marine applications, or other specialized needs, our goal is to provide custom battery cables that meet and surpass the demands of performance, durability, and corrosion resistance.