how to make a custom wire harness?

How to make a custom wire harness?

1. Design and Planning:

Firstly, conduct wiring harness design to determine the required wires, insulation materials, connectors, and other components. Determine the physical layout, length, and connection method of the wiring harness. Create detailed drawings and specifications for the wiring harness.

2. Material procurement:

Purchase the required components such as wires, insulation materials, connectors, sleeves, and cable straps. Ensure that all materials meet specifications and quality requirements.

3. Cutting and peeling:

Use automatic or semi-automatic equipment to cut wires to the required length. Strip the insulation of the wire for subsequent connection.

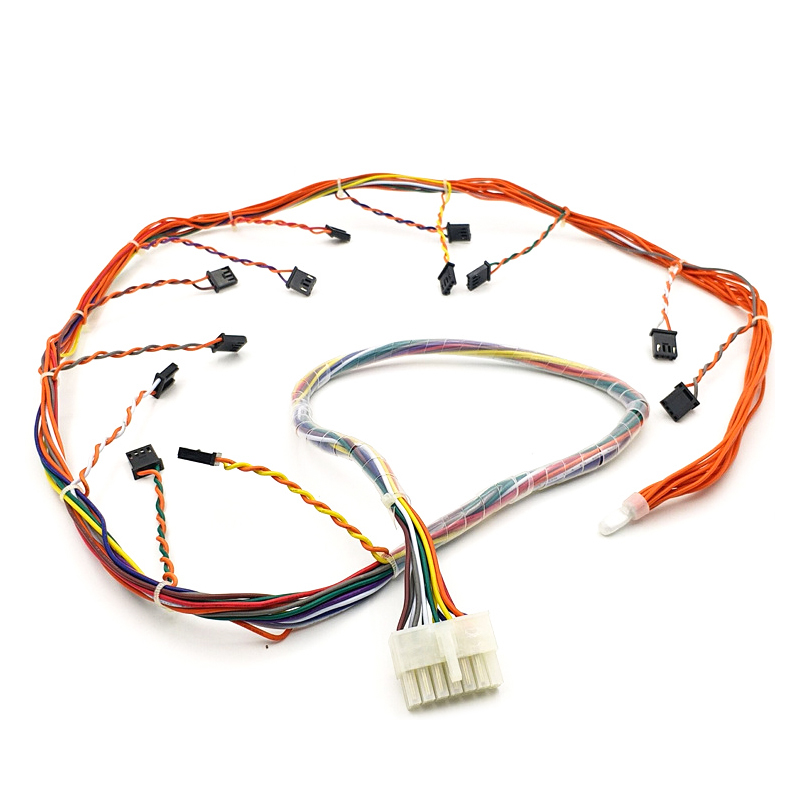

4. Assembly:

Assemble the wires into wire harnesses according to the requirements of the design drawings. Connect the wires to the appropriate connectors. Add insulation sleeves and markings.

5. Binding and Protection:

Use cable ties or other binding materials to tie the components of the wiring harness together to ensure the integrity and cleanliness of the wiring harness. Add protective sleeves, conduit, or sheaths to protect the wiring harness from mechanical damage and environmental impact.

6. Testing and Verification:

Conduct necessary tests on the wiring harness to ensure the reliability, electrical performance, and safety of the connection. Conduct connectivity testing to verify the correct connection of the circuit. High voltage testing, insulation testing, and electromagnetic compatibility testing may be required.

7. Marking and Identification:

Mark the various parts of the wiring harness for identification during installation and maintenance. Add labels, signs, or ribbons as needed.

8. Packaging and Delivery:

Package the finished wire harness to prevent contamination and damage. Delivery of wiring harnesses according to customer requirements may require adherence to specific packaging and labeling requirements.

9. Quality control:

Implement quality control procedures to ensure that the manufacturing process of wire harnesses meets design specifications and quality standards. Conduct quality audits and records to ensure that each wiring harness meets the requirements.

10 File records:

Maintain detailed production records, including drawings, specifications, test reports, and quality records. These records are crucial for product traceability and quality management.

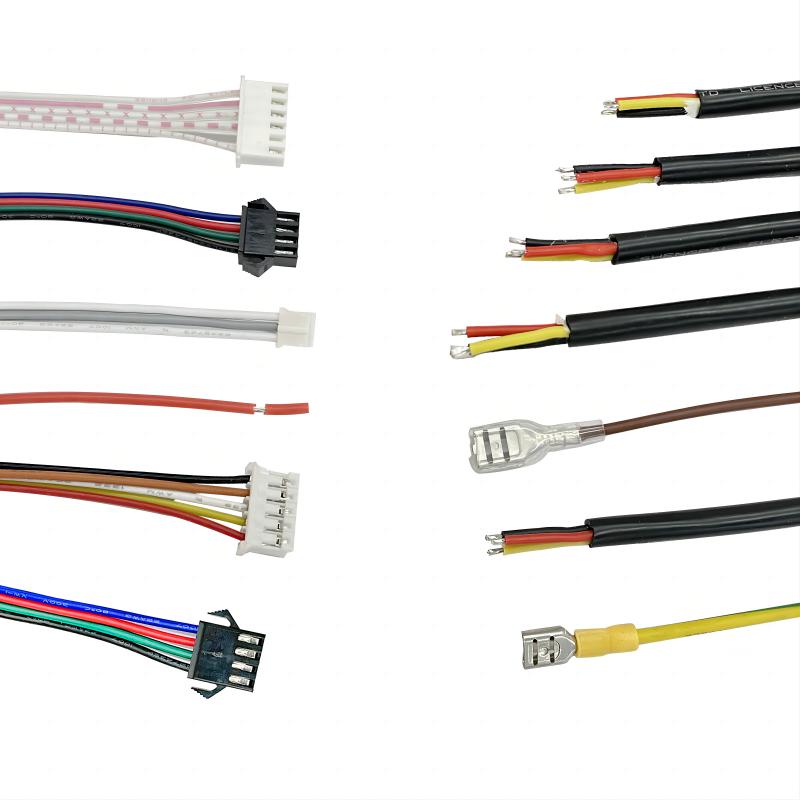

What is wiring harness connectors?

A wiring harness connector is a connector used to connect multiple electronic devices or wires. They are typically used in automobiles, airplanes, industrial equipment, and electronic devices to connect multiple wires or cables together for the transmission of electricity, signals, and data. The following are some common structural knowledge of wire harness connectors:

1. Plug and socket: A wiring harness connector usually consists of two main parts, namely the plug and socket. A plug is one side of a connector, usually containing pins or sockets, while a socket is the other side of the connector, accepting the plug.

2. Pins and sockets: A plug usually has a set of pins, while a socket has a matching socket. The number and arrangement of pins and sockets vary depending on the design and purpose of the connector.

3. Shell: The connector usually includes a shell to protect the plug and socket, while providing mechanical support and functions such as dust and water resistance. The shell is usually made of durable materials, such as metal or plastic.

4. Locking mechanism: To ensure the reliability of the connection, the harness connector is usually equipped with a locking mechanism that can securely connect the plug and socket together. This can be rotary locking, snap locking, or other types of mechanical locking.

5. Guidance signs: Some connectors have guidance signs or keys to ensure correct alignment and insertion of plugs and sockets. This helps to avoid incorrect insertion and ensure the correctness of the connection.

6. Sealing and Waterproofing Performance: Some wiring harness connectors are designed for use in harsh environments, thus possessing waterproof and sealing performance. These connectors are usually equipped with sealing rings or waterproof coatings to prevent water, moisture, and dust from entering the connectors.

7. Electronic characteristics: Wire harness connectors can also have electronic characteristics, such as shielding to reduce electromagnetic interference, and additional signal pins or connectors for transmitting data and control signals.

8. Multi pin connectors: Some wiring harness connectors have multiple pins and sockets, which can transmit multiple signals or power supplies simultaneously. This is very useful for applications that require high-density connections.

The structure of wire harness connectors may vary depending on different applications and manufacturers, but the above basic elements are usually included. The design and selection of these connectors usually depend on specific electronic system requirements and environmental conditions.

Types and differences of various assembly harness materials

There are various types of materials for electronic wiring harnesses, and the selection of appropriate materials depends on specific application requirements and environmental conditions. The following are some common types of electronic wiring harness materials and their main differences:

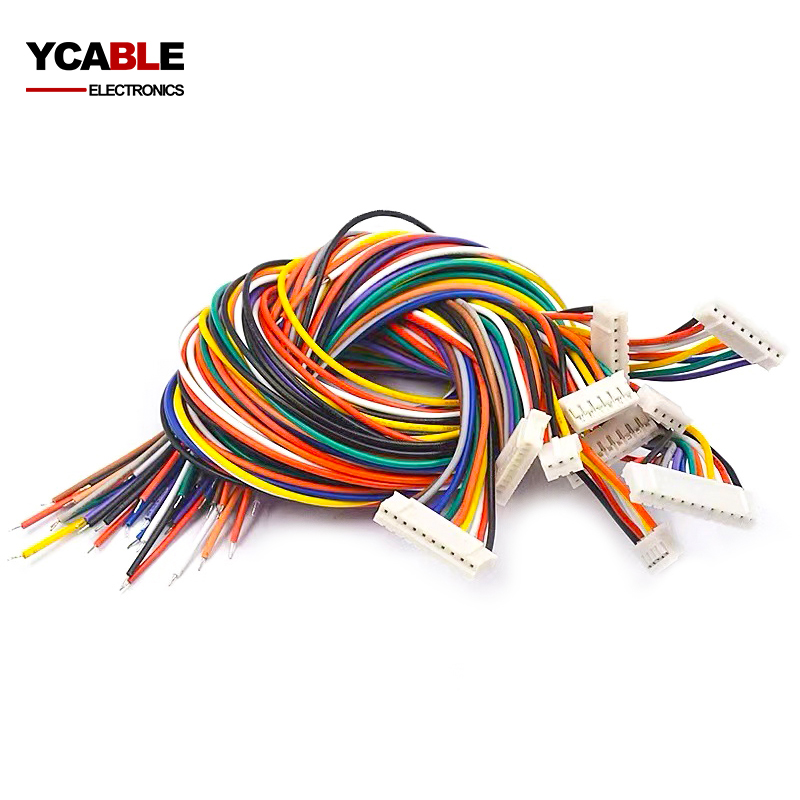

1. Wire and cable:

1.1 Wire: Usually refers to a single wire used to transmit current or signals. Usually made of copper, aluminum, or other conductive materials. Wires come in different specifications and insulation materials, and can be selected based on current capacity and usage.

1.2 Cable: includes multiple wires, usually composed of insulated wires, insulation layer, sheath, etc. Cables are typically used to organize multiple signal or power wires together, providing additional protection and neatness.

2. Insulation material:

2.1 PVC (polyvinyl chloride): A common insulation material with good electrical insulation performance, but may soften in high-temperature environments.

2.2 XLPE (cross-linked polyethylene): It has higher heat resistance and electrical properties, suitable for high-temperature applications.

2.3 Silicone: It has excellent high-temperature resistance, chemical corrosion resistance, and is suitable for use under extreme conditions.

2.1 PTFE (polytetrafluoroethylene): Very high temperature resistant, chemically stable, used in applications that require extremely high performance, such as aerospace.

3. Sheath material:

3.1 PVC sheath: A common sheath material that provides a certain degree of mechanical and environmental protection.

3.2 PUR (polyurethane) sheath: It has better wear resistance and oil resistance, and is suitable for industrial environments.

3.3 TPU (Thermoplastic Polyurethane) Sheath: It has high flexibility and is suitable for applications that require bending.

3.4 Metal sheath: Usually used in applications that require high mechanical protection and EMI (electromagnetic interference) protection, such as aerospace.

4. Connector: Different electronic connector materials (such as metal and plastic) and connector types (such as circular connectors and board to board connectors) are suitable for different application scenarios.

5. Binding and Protection Materials: Wire harnesses usually require binding and protection, and materials such as binding straps, heat shrink sleeves, and sheaths are used to ensure the cleanliness and protection of the wire harness.

6. Waterproof and environmentally resistant materials: Wiring harnesses used outdoors or in harsh environments may require special waterproof and environmentally resistant coatings or materials.

The material selection of wire harnesses depends on many factors, including electrical performance, environmental conditions, mechanical requirements, chemical resistance, and cost. When designing and selecting wiring harness materials, it is necessary to comprehensively consider these factors to ensure that the wiring harness can work reliably in specific applications.