Automotive High Voltage Wire Harness Manufacturer

High Voltage Wiring Harness Innovations

YCABLE ELECTRONICS, a versatile hub for electric vehicle high voltage wiring harness assemblies, specializes in both elevated and low voltage wiring harness configurations and electrical linkages.

YCABLE ELECTRONICS' Offerings in High Voltage Wiring Harness Services:

- Extensive assortment of EV HV connectors for secure, steadfast, and proficient linkages. The range includes renowned brands such as YCABLE ELECTRONICS Electronics, Amphenol, TK, Jonhon, Sumitomo, etc. We excel in amalgamating resources and providing the most economical options. Your specific high voltage wiring harness needs are our priority.

- High Voltage Wiring Harness Assembly Services.

- For those with components like connectors and cables but lacking in assembly capabilities, we offer a comprehensive suite of assembly and production services. Our state-of-the-art crimping technology ensures that the high-voltage wiring harness is perfectly safe for connecting high-voltage components in electric vehicles.

- Tailored support for all your high voltage wiring harness interconnection demands.

What is high voltage wiring harness?

Electric Vehicle High Voltage Wiring Harness Configuration Overview:

- Power Battery Cable: Connects the power battery to the high voltage distribution box.

- Motor Controller Cable: Links the high voltage distribution box to the motor controller.

- Rapid Charging Cable: Connects the rapid charging inlet to the high voltage distribution box.

- Standard Charging Cable: Joins the standard charging inlet to the vehicle charger.

- Accessory High Voltage Wiring Harness: Connects the high voltage distribution box to various components like DCDC, vehicle charger, air conditioner compressor, and PTC.

High Voltage Wiring Harness Design Criteria:

- DC high voltage circuits in the high-voltage system must adhere to a dual-track approach, avoiding the use of the vehicle body as a grounding point.

- The high-voltage wiring harness circuit should be fully shielded and interconnected, typically employing shielded high voltage cables to minimize EMI and RFI impacts. The shielding layer is connected to the motor controller housing and then grounded to the vehicle body.

- Voltage Endurance: Capable of withstanding 600/900VAC and 1000/1500VDC.

- Current Capacity: Ranging between 250~400A, based on component requirements.

- Temperature Tolerance: High temperature grades split into 125℃, 150℃, and 200℃, typically opting for 150℃ wires; low temperature standard at -40℃.

- Usage of thick-walled wires (wall thickness between 0.6~1.1mm).

- Wire Diameter Design involves factors like load circuit rated current, wire conductor temperature tolerance, surrounding ambient temperature, energization rate decrease due to wire heating, and bundled harness current allowance reduction.

- Verification Equation: Wire's permissible current × temperature rise de-energization rate reduction × bundling coefficient > load circuit rated current.

High Voltage Wiring Harness Layout Specifications:

- High-voltage components arrangement should maintain a minimum 110mm buffer from the vehicle body.

- High-voltage wiring harnesses should avoid crossing and should run parallel; divergences should be minimal.

- Minimum gap between adjacent parts ≥15mm, dynamic gap ≤25mm.

- Fixed points at bends are necessary to maintain alignment with design direction.

- Consideration of vehicle abrasion and sand impact on the wiring harness.

- Protection measures at sharp edges if unavoidable.

- Wiring harness bending radius ≥6D (D being the wiring harness diameter).

- Ambient temperature below 125℃.

- Fixed point spacing:

- For harness cross-sectional area > 16mm2, fixed point gap ≤ 300mm.

- For harness cross-sectional area < 16mm2, fixed point gap ≤ 200mm.

Comparing Automotive High Voltage Wiring Harnesses and Electric Vehicle Charging Harnesses

In new energy vehicle technology, wire harnesses are generally categorized into two distinct types:

Internal electric vehicle harnesses, comprising high voltage and low voltage wiring harnesses.

A separate category for electric vehicle charging harnesses.

Differences Between the Two:

Layout Variations:

- Automotive high voltage harnesses are fixedly laid, with smaller static bending radii.

- Charging harnesses are mobile, having smaller dynamic bending radii.

Heat Resistance Divergence:

- Automotive high voltage harnesses require higher heat resistance, starting from 125 degrees and reaching up to 180 degrees (silicone rubber) or 200 degrees (fluoro rubber).

- Charging harnesses, typically exposed externally, are designed to withstand temperatures not exceeding 70 degrees to avoid burn risks.

EMI Requirements:

- Automotive high voltage harnesses demand stringent EMI compliance to meet vehicle EMC standards.

- Charging harnesses, used when the vehicle is stationary, adhere to environmental EMC standards relevant to locations like gas stations and residential areas, rather than vehicle-specific EMC standards.

Protective Measures:

- Automotive high voltage harnesses necessitate comprehensive safety measures, including insulation, grounding systems, and shielding.

- Charging harnesses, while not requiring as extensive protective measures as high voltage harnesses, still need to be robust against impacts and UV radiation.

Physical Performance Expectations:

- Automotive high voltage harnesses must endure vehicle wear and tear.

- Charging harnesses are designed with anti-rolling features to maintain stability during movement.

Chemical Resistance:

- Automotive high voltage harnesses are constructed to resist a variety of vehicular liquids.

- Charging harnesses need to withstand diverse environmental liquids.

Size Specifications:

- Automotive high voltage harnesses are confined by spatial constraints, favoring smaller sizes.

- Charging harnesses, not limited by vehicle space, can be larger for enhanced current handling.

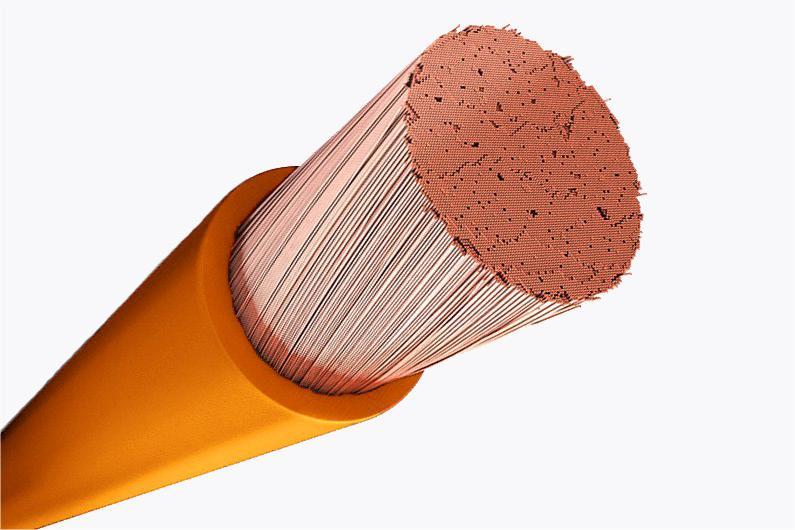

Color Standards:

- The standard color for automotive high voltage harnesses is orange for uniformity and safety.

- Charging harnesses do not require standardized coloring.

Core Count:

- Automotive high voltage harnesses typically use a single core.

- Charging harnesses often integrate multiple cores, including high-voltage, ground, low-voltage signal, and communication lines (e.g., CAN).

International Standards:

- Automotive high voltage harnesses adhere to ISO standards.

- Charging harnesses follow IEC standards.

New Energy High Voltage Wire Harness

Our assortment includes a variety of high voltage (HV) connection options:

- HV harnesses for new energy passenger cars, ensuring efficient energy transmission.

- Specially crafted HV harnesses for premium commercial buses, offering robust electrical connections.

- HV harnesses designed for trucks, tailored for heavy-duty applications.

- Custom HV harnesses for motorhomes, enhancing on-the-road energy needs.

- HV harnesses for construction machinery and vehicles, built to withstand rugged use.

- Sanitation vehicle HV harnesses, designed for reliability in cleaning operations.

- HV harnesses for energy storage systems, ensuring stable energy management.

BAT High Voltage Wire Harness

- Features high voltage interlock plastic connectors for safety and reliability.

- Supports voltage up to 1500V and currents between 20-300A.

- Operates efficiently in temperatures ranging from -40℃ to 180℃.

- Constructed with XLPE material for enhanced durability.

- Customizable according to specific customer requirements.

MCU High Voltage Wire Harness Assembly

- Utilizes multi-strand, finely twisted oxygen-free copper for flexibility.

- Can withstand voltage levels up to 1500V and currents from 20-300A.

- Temperature range of -40℃ to 180℃, suitable for various environments.

- Made with durable XLPE material.

- Offers customization options.

- Conductor choice includes copper or aluminum (as per request).

PTC&AC High Voltage Wire Harness

- Composed of flexible, multi-strand oxygen-free copper wire.

- Capable of handling 1500V voltage levels and 20-300A currents.

- Temperature resistant from -40℃ to 180℃.

- XLPE material construction for longevity.

- Customizable to meet specific needs.

DC-DC High Voltage Wire Harness

- Features multi-strand, finely twisted copper wire for superior flexibility.

- Designed to withstand 1500V and currents ranging from 20-300A.

- Operates efficiently within a temperature range of -40℃ to 180℃.

- Built with durable XLPE material.

- Customizable design to fit specific requirements.

Fast/Slow Charge High Voltage Harness

- Compliant with IEC 62196.3-2014 standards.

- Rated for 1000V/200A.

- Meets TUV/CE certification criteria.

- Tested for 12000 plug/unplug cycles, ensuring stable temperature performance.

- Customizable as per client specifications.

Drive Motor High Voltage Wire Harness

- Constructed with flexible, multi-strand oxygen-free copper.

- Suitable for 1500V voltage levels and currents between 20-300A.

- Temperature range from -40℃ to 180℃.

- Made with XLPE material for increased durability.

- Customizable, with conductor options including copper or aluminum.

Aluminum Conductor HV Wire Harness

- Utilizes friction welding to create a copper-aluminum alloy transition, sealed with glue-containing heat-shrinkable tube for corrosion protection.

- Proven reliability, electrical conductivity, and mechanical strength.

- Features a maximum resistance of 0.016mΩ and an average resistance of 0.013mΩ.

- Maximum temperature rise capped at 27.31℃.

- Average pull-off force of 4510N, with a minimum of 4340N.