OEM Custom Wire Harness Manufacturers Custom Cable Assembly Manufacturer

Customized exclusive wiring harness: Provide customized wiring harness design and processing services

We will introduce the precise processing and customization service of China custom wire harnesses and cable assembly

Custom harness manufacturers specialize in creating, well, custom wire harnesses to suit the specific needs of various applications. Whether you're dabbling in aerospace, healthcare, or have been mesmerized by the potential of the automotive industry like we have at YCABLE ELECTRONICS, these manufacturers are the go-to source for your tailored needs.

What is a custom wire harness?

Custom wiring harness is a wire connection solution tailored to the needs and requirements of customers. It consists of multiple wires, cable and connectors, used to connect various devices and systems. By customizing wiring harness and cable assembly, customers can obtain high-quality and reliable wire connection solutions that meet their specific needs. A wire harness is essentially a bundle of wires or cables designed to transmit signals or electrical power. It's your own personal subway system for electricity and data, with various stations—or in this case, connectors—along the route. A custom wire harness, on the other hand, is that tailored suit designed to fit you like a glove—or in this context, designed to fit the specific requirements of your product or project.

So there you have it, a custom wire harness is not just a bundle of wires. It's a meticulously designed, custom-fit solution that facilitates efficient, reliable, and safe transmission of electrical signals and power. And when you need it tailor-made, custom wire harness manufacturers are your go-to couturiers in this high-stakes fashion show of technology.

What is a OEM wiring harness?

First off, OEM stands for Original Equipment Manufacturer. When we talk about an OEM wiring harness, we're referring to a wire harness that's designed and produced to meet the manufacturer's specifications. Think of it as the electrical circulatory system, but created with a level of quality assurance that only comes from original equipment manufacturing.

An OEM wiring harness is usually pre-configured and will include all the connectors and terminals you need. Unlike custom wiring harnesses, which are tailored for unique situations, OEM versions are the reliable off-the-rack suits in a world filled with haute couture. They're made to fit a wide range of applications, but with the assuredness that they adhere to the manufacturer's stringent requirements.

"Why go OEM when custom wire harness manufacturers can tailor-make a solution?" The answer depends on your needs. OEM wiring harnesses are often more cost-effective and quicker to acquire, but they may not fit specialized needs like a glove, as a custom harness would. Both have their places; it's like choosing between a fine-tailored suit and a high-quality ready-to-wear ensemble.

Why choose precision processing and customized services for custom wire harness

Precision machining and customization services provide customers with the convenience and advantages of custom wiring harnesses and custom cable assembly. Through precise processing and customized services, customers can benefit from the following:

Personalized customization: Custom the length, color, material, etc. of the exclusive wiring harness according to the specific needs of the customer. The need for custom solutions is especially acute in specialized or complex environments. Here, generic solutions often prove inadequate. Customized services offer the flexibility to adapt to complex configurations, variable lengths, and specific connector types, thereby ensuring a perfect fit for your specialized needs.

Precision processing: Adopting advanced processing equipment and technology to ensure the precise processing and quality of wire harness and cable assembly. When it comes to wire harnesses, precision isn't just a buzzword; it's a requirement. Precise cuts, exact lengths, and pinpoint accurate connections are what differentiate an effective wire harness from one that’s merely decorative. Precision processing ensures that each component fits its purpose flawlessly, reducing the margin for errors, malfunctions, or safety risks.

Reliability assurance: Through strict quality control and testing, ensure the reliability and durability of customized wiring harnesses and cable assembly. At YCABLE ELECTRONICS, we've got you covered on both fronts. Our ISO 9001 and TS 16949 certifications testify to our commitment to quality. Add to that our willingness to entertain low MOQ orders, and you have a winning combination of precision and customization.

Fast delivery: Precision processing and customized services can provide fast delivery to meet urgent customer needs. Add to that our willingness to entertain low MOQ orders for custom wire harness and cable assembly, and you have a winning combination of precision and customization.

If precision processing is the brush, then customized services are the palette of colors at your disposal. Custom wire harness manufacturers, like YCABLE ELECTRONICS, offer the ability to tailor each aspect of your wire harness to the unique needs of your application—whether you're in aerospace, healthcare, or basking in the fast lane of the automotive industry.

How to carry out precise processing and custom wire harness and cable assembly?

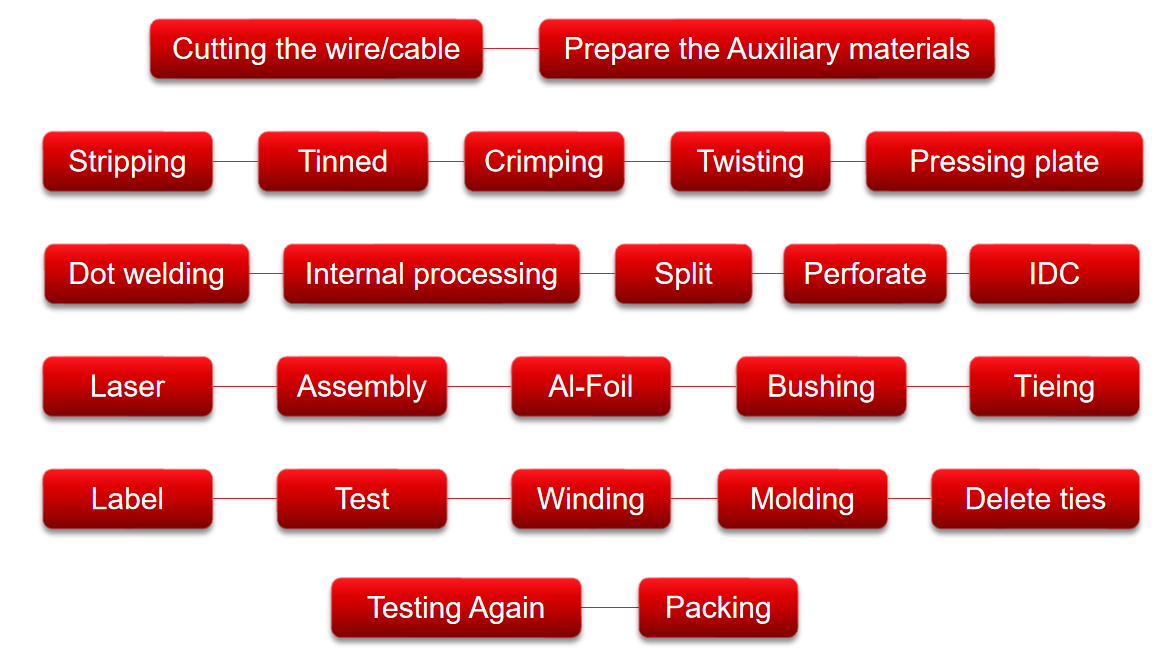

The steps for wire harness and cable assembly customization are as follows:

Requirement confirmation: Communicate with customers to understand their specific needs and requirements for the wire harness. Analyze the application where the wire harness or cable assembly will be used. Gather specifications such as voltage requirements, signal types, and environmental conditions. This stage is all about gathering the 'what,' 'where,' and 'how' to tailor the best solution possible.

Design scheme: Design a customized wiring harness scheme according to the customer's needs. Based on the requirements, conjure a design that meets or exceeds the given specifications. Using CAD software or specialized wire harness design tools, develop a prototype. This blueprint will serve as the roadmap for custom wire harness manufacturers throughout the manufacturing process.

Material procurement: Purchase wires, cables, and connectors that meet the requirements. Choose materials that align with the application's demands. This means picking the right type of wire, insulation material, and connectors. Here, consider factors such as temperature resistance, tensile strength, and flexibility.

Processing and manufacturing: Using advanced processing equipment and technology for wire harness and cable assembly precise processing and manufacturing.

-

Precision Cutting and Stripping. This is where the 'precision' in precision processing really kicks in. Cut the wires to the exact lengths needed, and strip away the insulation where connectors will be attached. Remember, a millimeter off can lead to complications down the road.

- Assembly and Soldering. Once cut and stripped, assemble the wires according to the design. This may involve crimping terminals onto the wire ends or soldering them in place. Your precision here ensures a snug fit and optimal performance.

Quality inspection: Conduct strict quality inspection and testing on customized wiring harness. rigorously test the custom wire harness or cable assembly to ensure it meets all functional, safety, and performance requirements.

Delivery service: deliver customized wiring harnesses on time and provide after-sales service.

Precision processing and custom services in wire harness and cable assembly are more of an art than a mere task. When conducted meticulously, it translates into optimized performance, safety, and durability, serving as the backbone for various applications.

Advantages of Custom Wiring Harnesses

Custom wiring harnesses have the following advantages:

Improving efficiency: Customizing wiring harnesses can reduce installation time and workload, and improve production efficiency.

Cost reduction: Customized wiring harnesses can reduce material waste and labor costs, reducing overall costs.

Optimizing performance: Customized wiring harnesses can provide better electrical performance and signal transmission quality.

Enhanced reliability: Customized wiring harnesses have undergone strict testing and quality control, resulting in higher reliability and durability.

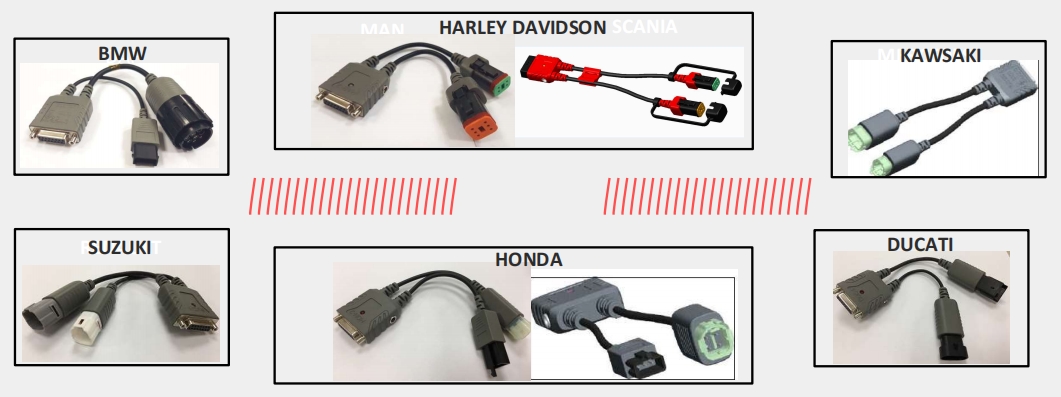

What wire harnesses can YCABLE ELECTRONICS customize?

-

Custom Automotive Wire Harness

-

Custom Waterproof Cable Assembly

-

Custom Battery Cable Assembly

-

Custom Patch Cords

-

Custom Power Cords

-

Custom Fiber Optic Cable Assembly

-

Custom Medical Cable Assemblies

-

Custom Over Molded Cable Assembly

-

Custom PCBA cable assembly

-

Custom solar cable assembly

Why Choose YCABLE ELECTRONICS for Your OEM Wire Harness and Custom Cable Assembly Needs?

Why entrust YCABLE ELECTRONICS with your OEM wire harness and custom cable assembly needs? Well, let’s go beyond the surface-level schmoozing and dig into the concrete reasons. Buckle up; you're in for a compelling read.

Experience & Expertise

Founded in 2012, YCABLE ELECTRONICS has accumulated a wealth of experience in the field. We started with a focus on cables and wires and soon pivoted towards the automotive industry, continually evolving to meet the market's ever-changing demands. We're not just riding the wave; we're shaping it.

Certifications That Speak Volumes

In 2020, our Guangdong factory achieved ISO 9001 and TS 16949 certifications, establishing our commitment to quality and international standards. These aren't mere badges; they're testaments to our devotion to delivering world-class products.

Customization Meets Precision

At YCABLE ELECTRONICS, custom wire harness manufacturers find a sanctuary. We offer bespoke solutions tailored to your precise needs. Whether it's a complex configuration in aerospace or a high-performance requirement in automotive, our custom services are the epitome of precision and reliability.

The OEM Edge

When it comes to OEM wire harness solutions, we offer products that are meticulously designed to meet manufacturer specifications. Our OEM services are the perfect blend of speed, efficiency, and quality assurance. It's like the express train service of the wire harness world.

Low MOQ, High Flexibility

Our ability to accept low MOQ orders means we're as committed to small enterprises as we are to big players. It's not just about quantity; it's about building lasting partnerships based on trust and quality.

After-Sales Service: The Cherry on Top

We believe the customer relationship doesn't end when the product leaves the factory. Our after-sales service is geared to ensure you are satisfied with our products long after the initial purchase. Our commitment to you is not just a one-time deal; it's a long-term promise.

Special Focus on Automotive

Since our shift towards the automotive industry, we have stayed ahead of the curve in a sector that is both dynamic and demanding. From electric vehicles to smart tech integrations, our solutions are designed to meet the rigorous requirements of modern automotive applications.

Choosing YCABLE ELECTRONICS is not just a transaction; it’s an investment in quality, reliability, and innovation. We strive to be not just vendors but trusted partners in your journey towards electrical and technological excellence.

So, whether you're in the market for an OEM wire harness or require custom cable assembly services, YCABLE ELECTRONICS is the name to trust. Got inquiries? We're all ears and ever-ready to offer top-tier solutions tailor-made for your needs.

Case Study

The following is an example case that demonstrates the application of custom wiring harnesses:

A certain automobile manufacturing company needs to customize a dedicated wiring harness for the electrical system of the vehicle. They chose precision machining and customized services, and collaborated with suppliers to design and manufacture customized wiring harnesses. By customizing the wiring harness, they successfully solved the complexity and diversity issues of vehicle electrical systems, improving production efficiency and quality.

So we can customize various wiring harnesses, which can be from cars, electrical appliances, mechanical equipment, and medical devices.

The precise processing and customization service of customized wire harnesses provides customers with personalized and reliable wire connection solutions. Through precise machining and customization, customers can obtain customized wiring harnesses that meet their specific needs and enjoy higher efficiency, performance, and reliability. Choosing precise processing and customized services is the best choice to meet customer needs.