What is the heating wire?

What is a heating wire?

A heating wire, also known as an electric wire or heater wire, is a device used for heating. It is mainly made of a metal material, usually nickel chromium alloy (such as nickel chromium wire, nickel chromium alloy wire) or other high resistance materials(such as carbon fibre). These metals generate heat energy when an electric current passes through them, thereby achieving the purpose of heating. The heating wire is widely used in various heating equipment, such as Electric blanket, electric heater, electric kettle, electric iron, water heater, etc.

What is the application of the heating wire?

Heating wire is widely used in various fields, mainly in heating and insulation equipment. The following are some common application scenarios:

- Household appliances: Electric blanket, electric kettle, electric iron, electric oven, electric water heater, Fan heater, etc.

- Industrial applications: heat treatment equipment, dryers, boilers, furnaces, electric furnaces, etc.

- Automotive industry: heated seats, heated steering wheels, defrosters, etc.

- Medical equipment: medical heating blankets, medical equipment disinfection equipment, etc.

- Agricultural applications: greenhouse heating, incubators, insulation boxes, etc.

- Scientific research: laboratory heating equipment, constant temperature incubator, etc.

What is the classification of heating wire?

The heating wire is classified according to different materials and can be classified based on its conductivity and heat resistance. The following are some common classifications of heating wire materials:

According to the heating material:

Metal heating wire:

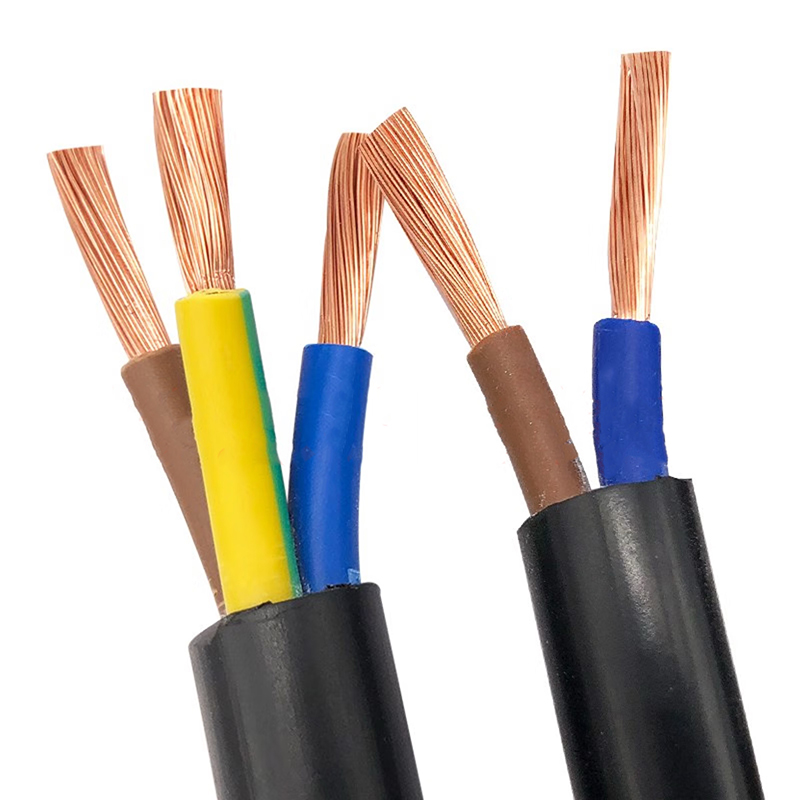

Metal heating wire is a common type of heating wire, usually made of materials such as nickel chromium alloy, iron chromium alloy, stainless steel, etc. This kind heating wire is normally insulated by silicone, PVC, or Teflon material. Metal heating wire have excellent thermal conductivity and high melting point, making them widely used in industrial and household heating equipment.

- The nickel chromium alloy heating wire has good temperature resistance and can usually work in temperature environments below 1000 ℃. This type of heating wire is widely used in high temperature heating, kilns, electric heating pipes, and other occasions.

- The iron chromium aluminum heating wire has high temperature resistance and oxidation resistance, and can work at higher temperatures. Iron chromium aluminum heating wire is suitable for heating systems in homes, offices and other places as well as industrial heating applications.

- The copper nickel heating wire has good temperature resistance and can work at higher temperatures. This type of heating wire is suitable for situations that require rapid heating and high requirements for material corrosion, such as solar water heaters, electric faucets, etc.

Carbon fiber heating wire:

Carbon fiber heating wire is woven from carbon fiber filament, which has the advantages of lightweight, efficient, and corrosion resistance. Due to the excellent thermal conductivity of carbon fiber, carbon fiber heating wire can quickly transfer heat during heating, and is widely used in floor heating, Electric blanket and other fields. There are silicone carbon fiber heating wire and Teflon(FEP or PFA) carbon fiber heating wire, Carbon fiber heating wire have good temperature resistance and are usually able to operate at higher temperatures. In an ideal working environment, the temperature resistance range of carbon fiber heating wire is -60 ℃ to 260 ℃. However, the temperature resistance performance in practical applications will be affected by environmental conditions, the structure of the heating wire, and the way it is used.

Semiconductor heating wire:

Semiconductor heating wire is made of semiconductor materials with high thermal conductivity, such as silica gel, alumina, etc. Semiconductor heating wire have the advantages of high thermal efficiency, fast response speed, and small thermal inertia, and are widely used in heating films, heating plates, and other equipment.

Silicone heating wire:

Silicone heating wire usually has good temperature resistance and can operate within the temperature range of -60 ℃ to 200 ℃. Silicone heating wire is widely used in heating systems in homes, offices and other places.

Silicon carbide (SiC) heating wire: The silicon carbide heating wire has good temperature resistance and can work in higher temperature environments. Silicon carbide heating wire are suitable for industrial heating, solar collectors, and other applications.

Oxide ceramic heating wire:

The temperature resistance of oxide ceramic heating wire varies depending on the type of material, but usually has good high temperature resistance. Oxide ceramic heating wire are widely used in heating systems in homes, offices and other places as well as in some industrial fields.

Teflon heating wire:

It is a special type of heating wire mainly made of Teflon (polytetrafluoroethylene, PTFE, FEP, PFA) insulation material. Teflon is a polymer material with excellent performance, widely used in various engineering fields under harsh environments such as high temperature, high pressure, and strong corrosion. Teflon has excellent high temperature resistance and can usually be used in the temperature range of -200 ℃ to 260 ℃. Some special models can even withstand high temperatures of 300 ℃.

Carbon Fiber Heating Wire: A Quick Overview

Carbon fiber heating wire is an innovative product used primarily for its exceptional heating properties. But what makes it stand out? Let's break it down:

Composition

Carbon fiber heating wires are primarily composed of carbon fibers. These fibers are known for their high tensile strength, electrical conductivity, and thermal conductivity.

Functionality

Unlike traditional metallic wires, carbon fiber heating wires produce heat through the resistance of the carbon fibers. This makes them highly efficient and allows for consistent and even heat distribution.

Applications

Given its properties, carbon fiber heating wire is used in a range of applications. From underfloor heating systems, heated clothing, to automotive applications – the possibilities are expansive. Particularly, for a manufacturer focused on the automotive sector, like YCABLE ELECTRONICS, integrating carbon fiber heating wires can enhance the functionality of products, offering more efficient heating solutions in vehicles.

Advantages

Efficiency: Carbon fiber heating wires heat up rapidly and maintain a consistent temperature.

Flexibility: These wires are flexible, making them suitable for diverse applications.

Durability: Carbon fibers resist oxidation and have a long lifespan.

Safety: They do not easily overheat, reducing fire risks.

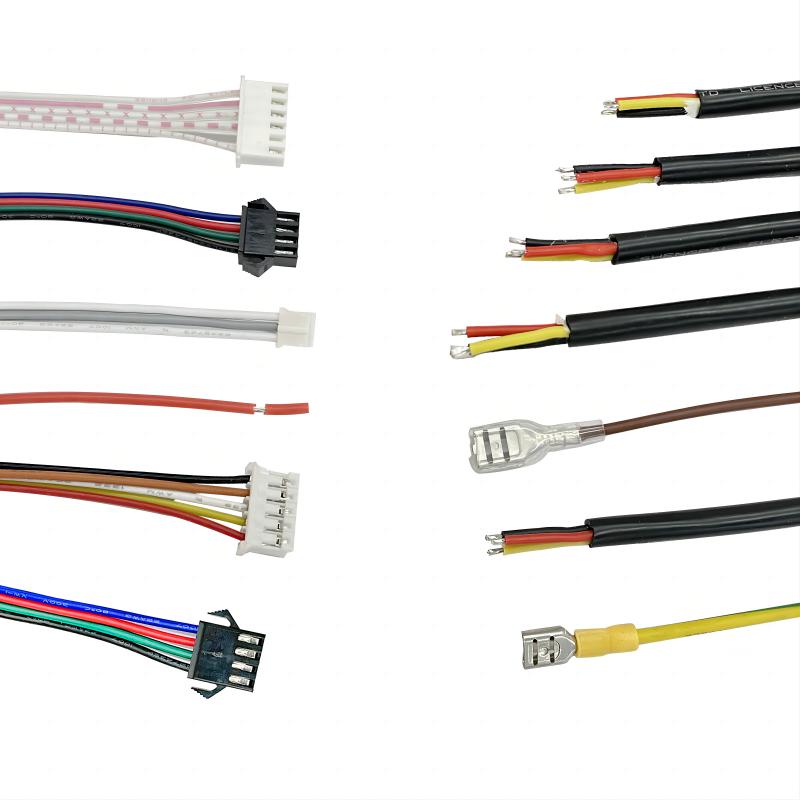

Incorporation with Cable and Wire Assembly

For a manufacturer, especially one versed in wire harness and cable assembly, carbon fiber heating wire presents an opportunity. Integrating this advanced material into cable assemblies ensures a product that's both durable and highly functional.

In conclusion, carbon fiber heating wire is an exciting advancement in the world of heating solutions. As a manufacturer, there's a lot of potential in harnessing its capabilities, especially in fields like automotive where consistent and efficient heating is paramount. It's no wonder that savvy manufacturers are keen on exploring this material further!