high temperature wire and Teflon wire manufacturer and supplier in China

What is a high temperature wire?

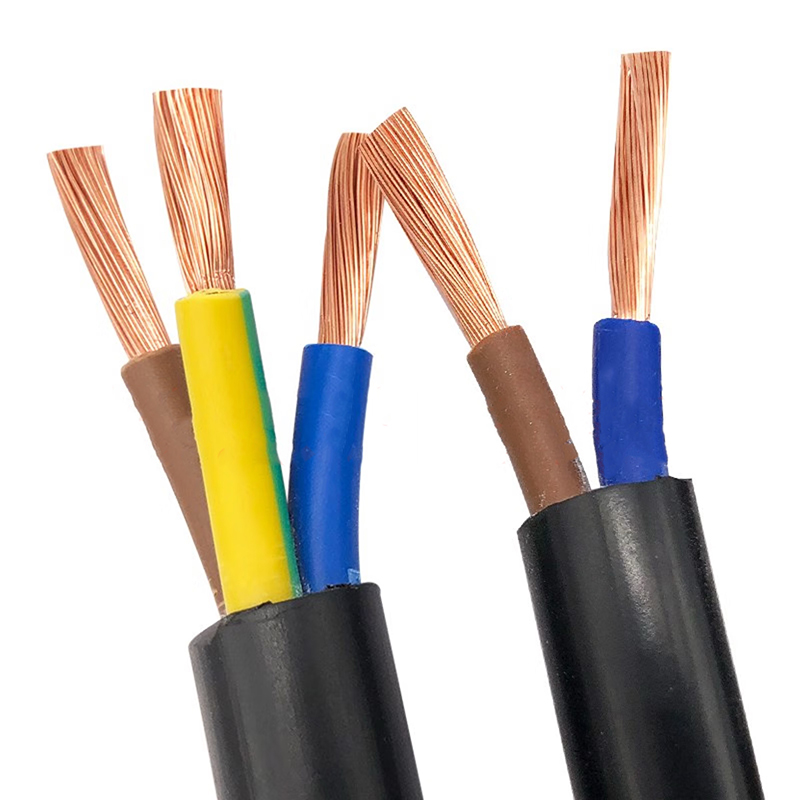

High temperature cable refers to a cable that can operate normally in a high temperature environment. This type of cable is typically used for electronic equipment, industrial equipment, and transportation in high temperature environments to achieve signal transmission and power supply functions. The material, structure, and performance of high temperature wires are different from ordinary wire and cable. They can withstand higher temperatures while maintaining good electrical and mechanical properties.

What are the types of high temperature wire?

There are various types of high temperature wires that can be classified according to different materials, structures, and application fields. The following are some common types of high temperature wires:

-

Silicone wire: Silicone wire is made of silicone rubber material and has excellent heat resistance, cold resistance, weather resistance, and chemical corrosion resistance. It has a temperature resistance of 200 degrees, and the wires are relatively soft with good bending performance. Due to its affordable price, it is suitable for various high temperature, low temperature, and harsh environments.

- Teflon wire: Teflon wire, also known as fluoroplastic insulated wire, like PFA, FEP, PTFE, ETFE, or MFA as insulation and sheath materials. It can withstand high temperature of 250 degrees Celsius and has excellent high temperature resistance, chemical corrosion resistance, and weather resistance. Teflon wires are commonly used in high temperature, high humidity, and highly corrosive environments such as aerospace, chemical, and petroleum. Because the thickness of Teflon material is relatively thin and the wires are relatively thin, it is widely used in precision instruments and equipment.

- Polyimide wire: Polyimide wire takes polyimide as the base material, which is also called enameled wire. It can withstand temperature up to 300C and has excellent heat resistance, electrical performance and mechanical strength. Polyimide wire is widely used in high temperature environment of electronics, automobile, aviation and other fields.

- Fire resistant wire: The fire resistant wire is made of refractory materials and has high fire resistance performance. The commonly used fire resistant wire is the fire alarm cable, which is often used in firefighting equipment, high temperature furnaces, power facilities, and other occasions.

- Glass fiber wire: Glass fiber wire is based on glass fiber and has excellent heat resistance, chemical corrosion resistance, and radiation resistance. The maximum temperature resistance can reach 1000 degrees, and fiberglass wire is commonly used in fields such as aerospace, nuclear energy, and medical treatment.

What is a Teflon wire?

Teflon high temperature wire was originally a type of high temperature cable made of polytetrafluoroethylene (PTFE wire, commonly known as Teflon wire). Later, other new fluoroplastic materials were developed, including PFA wire, FEP wire , EFTE wire , MFA wire, etc. Teflon has many excellent properties, such as high temperature resistance, chemical corrosion resistance, weather resistance, high insulation, low friction coefficient, etc. Therefore, it is widely used in equipment and electronic circuits under harsh environments such as high temperature, high humidity, strong acid and alkali.

Specification of Teflon wire

| 线规 | 导体结构 根数/线径 | 绝缘厚度 | 平均外径 | 20 ℃时导体直流电阻 | 包装长度 |

|---|---|---|---|---|---|

| 10 | 37 × 0.43 | 0.33 | 3.67 | 3.546 | 305 |

| 12 | 19 × 0.49 | 0.33 | 3.11 | 5.64 | 305 |

| 14 | 19 × 0.37 | 0.33 | 2.51 | 8.96 | 305 |

| 16 | 19 × 0.30 | 0.33 | 2.16 | 14.6 | 305 |

| 17 | 19 × 0.26 | 0.33 | 1.96 | 18.3 | 305 |

| 18 | 19 × 0.23 | 0.33 | 1.81 | 23.2 | 305 |

| 20 | 19 × 0.20 | 0.33 | 1.61 | 36.7 | 305 |

|

| 1 × 0.80 | 0.33 | 1.46 | 35.2 | 305 |

| 22 | 19 × 0.16 | 0.33 | 1.46 | 59.4 | 610 |

|

| 1 × 0.65 | 0.33 | 1.31 | 56.4 | 610 |

| 24 | 7 × 0.20 | 0.33 | 1.26 | 94.2 | 610 |

|

| 1 × 0.50 | 0.33 | 1.16 | 89.3 | 610 |

| 26 | 7 × 0.16 | 0.33 | 1.14 | 150 | 610 |

|

| 1 × 0.40 | 0.33 | 1.06 | 143 | 610 |

| 28 | 7 × 0.12 | 0.33 | 1.02 | 239 | 610 |

|

| 1 × 0.32 | 0.33 | 0.98 | 227 | 610 |

| 30 | 7 × 0.10 | 0.33 | 0.96 | 381 | 610 |

|

| 1 × 0.254 | 0.33 | 0.914 | 361 | 610 |

The classification of Teflon high temperature wire.

Classification by structure:

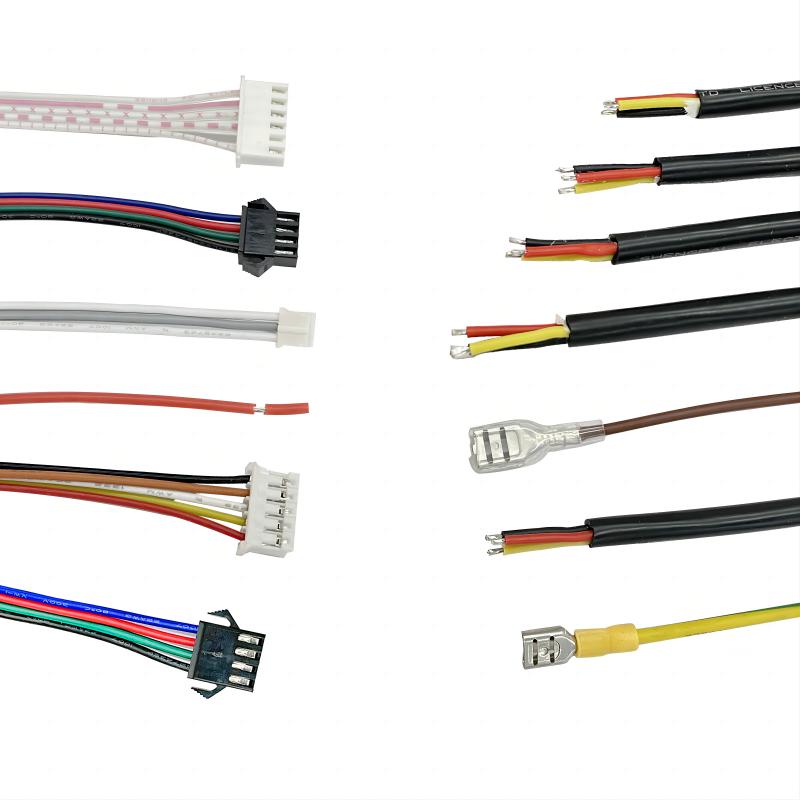

- Teflon single core wire: Single core Teflon high temperature wire consists of an insulated Teflon wire and a sheath. Single core wires are suitable for simple signal transmission and power supply wires.

- Multi cores Teflon cable: Multi core Teflon high temperature cable is composed of multiple insulated Teflon cable, usually in a symmetrical or asymmetric layout. Multi core cables are suitable for complex signal transmission and power supply wires, such as data cables, power cables, etc.

Classification by purpose:

- Signal transmission Teflon wire: Teflon high temperature signal transmission wire is mainly used for transmitting electrical signals, such as data cable, coaxial cable, etc. This type of cable has good electrical performance and anti interference performance.

- Teflon Power cord cable: Teflon high temperature power cord cable is mainly used for transmitting electrical energy, such as AC power cord, DC power cord, etc. This type of cable has excellent electrical insulation performance and safety performance.

- Teflon control cable: Teflon high temperature control cable is mainly used for controlling equipment, such as sensor signal wires, servo control wires, etc. This type of cable has high accuracy and stability.

Classification by material:

- PTFE Teflon wire: It has a temperature resistance of 260 degrees. This type of Teflon high temperature wire is made of polytetrafluoroethylene (PTFE) and has good properties such as high temperature resistance, chemical corrosion resistance, and weather resistance.

- FEP Teflon wire: It has a temperature resistance of 200 degrees. FEP Teflon wire is made of fluoroplastic (FEP) and also has excellent properties such as high temperature resistance, chemical corrosion resistance, and weather resistance. Compared with PTFE Teflon wire, FEP Teflon wire has slightly lower mechanical strength and wear resistance, but lower cost.

- PFA wire, temperature resistance of 250 degrees Celsius is slightly higher than FEP

- ETFE wire has a temperature resistance of 150 degrees, which is the lowest in Teflon, but it has the highest softness and stronger wear resistance.

What is the difference between FEP wire and PTFE wire?

What is PTFE wire?

PTFE wire is a type of wire made of polytetrafluoroethylene (PTFE). Due to its many excellent properties, such as excellent high temperature resistance, chemical corrosion resistance, weather resistance, high insulation, low friction coefficient, etc., PTFE wire is widely used in equipment and electronic circuits under harsh environments such as high temperature, high humidity, strong acid and alkali. It has characteristics such as high temperature resistance, chemical corrosion resistance, weather resistance, high insulation, and low friction coefficient.

What is FEP wire?

FEP wire is a type of wire made of fluorinated ethylene propylene copolymer (FEP). FEP is a thermoplastic with excellent performance, characterized by high temperature resistance, chemical corrosion resistance, weather resistance, high insulation, and low friction coefficient. Widely used in electronic and industrial equipment under harsh environments such as high temperature, high humidity, and strong acidity and alkalinity.

Compared with PTFE wire, FEP wire has slightly lower mechanical strength and wear resistance, but its cost is relatively low. FEP wire is an economical and practical choice.

Chemical structure: PEP wire is made of Polyether ether ketone (PEEK), and PTEP wire is made of blending of polytetrafluoroethylene (PTFE) and Polyether ether ketone (PEEK). This blend combines the advantages of PTFE and PEEK, such as high temperature resistance, chemical corrosion resistance, high insulation, and low friction coefficient.

Heat resistance: The continuous use temperature range of PEP wire is generally 50 ℃ to+200 ℃,

The high temperature resistance of PTEP wire depends on the blending ratio of polytetrafluoroethylene (PTFE) and Polyether ether ketone (PEEK), but its maximum operating temperature is usually about 250 ℃.

Chemical corrosion resistance: Both PEP and PTFE wires have excellent chemical corrosion resistance and can resist the erosion of various chemical media such as acids, alkalis, and salts.

Mechanical strength: The mechanical strength of PTFE is slightly better than that of PEP,

Overall, both PEP wire and PTEP wire are wires made of high performance engineering plastics, which have characteristics such as high temperature resistance, chemical corrosion resistance, high insulation, and low friction coefficient. They have interchangeability in certain application scenarios, but their specific selection needs to be based on actual needs and environmental conditions.

What is Teflon wire? Teflon Wire: An In-Depth Look

Teflon is a registered trademark of Chemours, but the material itself is known as Polytetrafluoroethylene (PTFE). When it comes to wiring, Teflon/PTFE is an outstanding insulation material. But why? Let's break down its characteristics:

Composition

Teflon wires are standard wires, be it copper or another conductor, but they are insulated with a layer of Teflon.

Properties

-

High Temperature Resistance: Teflon wires can operate at temperatures ranging from -65°C to +260°C, making them ideal for extreme conditions.

-

Chemical Resistance: PTFE is resistant to most chemicals, solvents, and corrosive environments.

-

Low Coefficient of Friction: This means Teflon wires are less likely to wear out due to friction, enhancing their lifespan.

-

Dielectric Strength: They're excellent insulators, making them safe and effective for electrical applications.

Applications of Teflon wire

Given their resilient properties, Teflon wires find their use in a variety of demanding sectors:

-

Aerospace

-

Military equipment

-

Medical devices

-

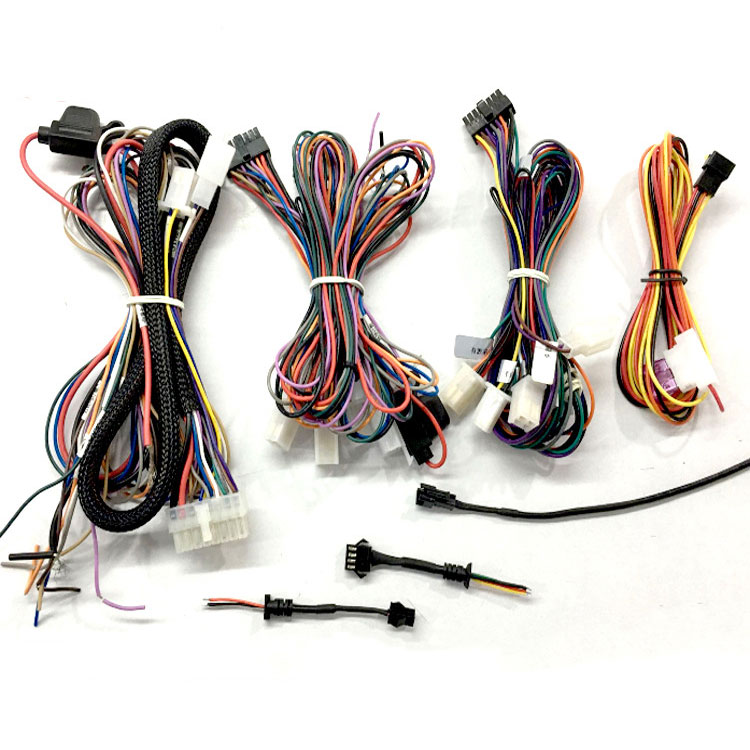

Automotive applications – particularly for manufacturers like YCABLE ELECTRONICS that specialize in cable assembly and wire harness solutions.

Types of Teflon Wires

There are a few types of Teflon wires based on their construction:

-

PTFE insulated wire: Standard Teflon insulation.

-

FEP insulated wire(Fluorinated Ethylene Propylene): Offers similar properties as PTFE but with a lower heat tolerance.

-

PFA insulated wire(Perfluoroalkoxy): Combines the properties of PTFE and FEP, offering flexibility and a wide temperature range.

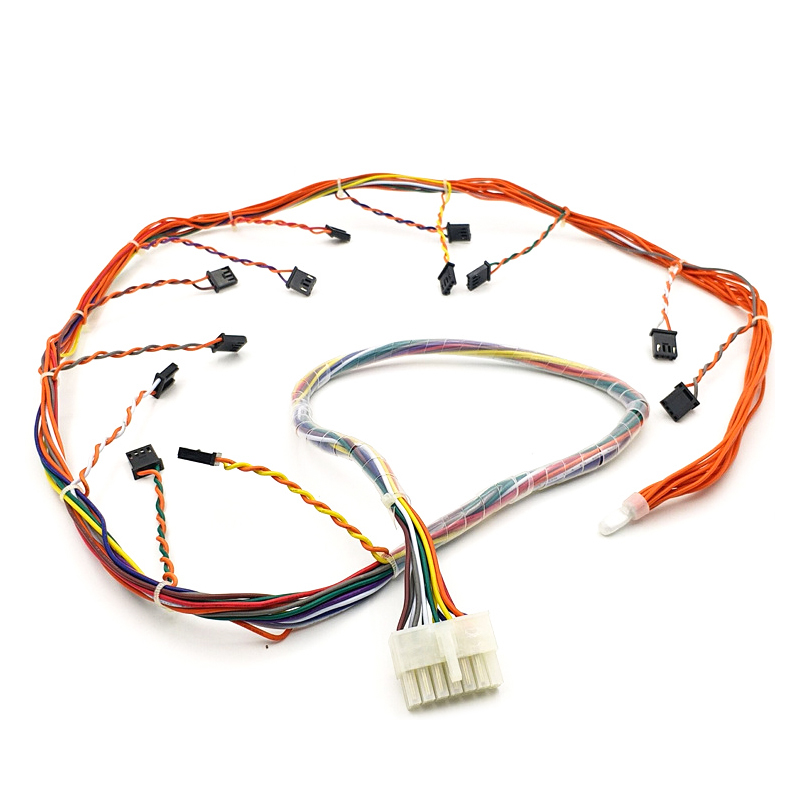

Integration with Cable and Wire Assembly

For a manufacturer, integrating Teflon wires within cable assemblies and wire harnesses can enhance product resilience, especially in environments that demand high-performance materials. With their ability to resist extreme temperatures and chemicals, they become a reliable choice for critical applications.

In essence, Teflon wire isn't just another wire; it's the superhero of the wiring world, ensuring safety and efficiency even under challenging conditions. Manufacturers who value reliability, especially in fields like the automotive industry, would do well to integrate such a robust material into their offerings. Always ahead, always resilient!