Fiberglass silicone wire

Fiberglass silicone wire

Item Number:Silicone wire

- Model: Fiberglass silicone coated wire

- Size: 0 GA-36 Gauge

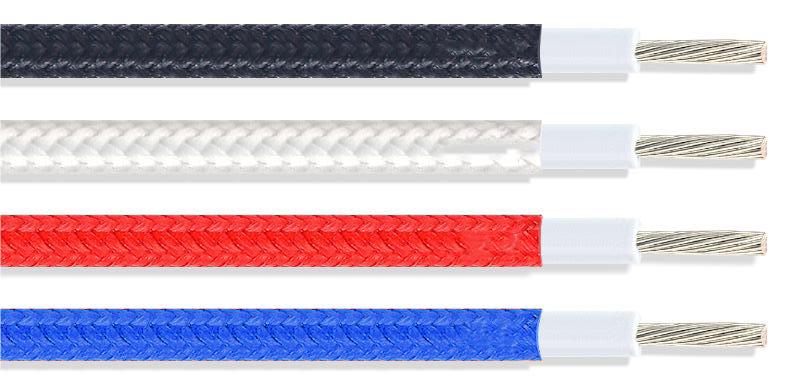

- Color: Transparent, black, green, red, yellow, white, Custom

- Insulation: silicone/silicone rubber

- Shield: None

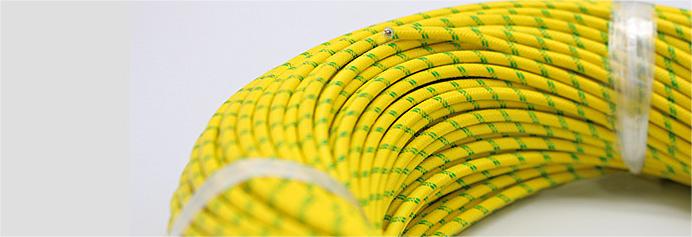

- Jacket: Fiberglass braiding

- Packing: 305m, 610m, 2000, 4000m, Custom

- OD: According to the standard/Custom

- Conductor Material: Tinned copper, silver plated copper, bare copper

- Drain wire: None

Environmental Specifications:

Environmental Space – Non-plenum

Flame Test Method – VW-1 FT-2

Installation Temperature – -40 °C to +250 °C

Operating Temperature – -40 °C to +250 °C

Temperature Rating – 200 °C / 250 °C

General Specifications:

Cable Type

High temperature Fiberglass silicone wire

Cable Component Type

Silicone

Conductor Gauge, singles

0AWG-36AWG

Conductor Type, singles

Solid/Stranded Single Core Wire

Characteristics:

- High temperature Fiberglass silicone wire products:

- Temperature resistance 250 degrees

- Oil resistance, acid, and alkali resistance

- Virtually eliminates skin irritation

- Color stable at elevated temperatures

- Suitable for UV, ozone, or moisture exposure

- Suited for liquid-immersed/High temperature applications

- Suitable for applications to -40°C~250°C

Fiberglass silicone wire is a very good high temperature wire, Silicone material is very stable, It can be used in many harsh environments for a long time, and the wire made of Silicone rubber is thinner than the high temperature wire made of other materials.

Categories

Fiberglass silicone coated wire

| Fiberglass Silicone Wire Specifications | |||||

| AWG | Conductor structure number/wire diameter(mm) | Insulation thickness (mm) | Average outer diameter(mm) | Conductor DC resistance at 20 ℃ (Ω/km) | Package length (m) |

| 10 | 37 × 0.43 | 0.33 | 3.67 | 3.546 | 305 |

| 12 | 19 × 0.49 | 0.33 | 3.11 | 5.64 | 305 |

| 14 | 19 × 0.37 | 0.33 | 2.51 | 8.96 | 305 |

| 16 | 19 × 0.30 | 0.33 | 2.16 | 14.6 | 305 |

| 17 | 19 × 0.26 | 0.33 | 1.96 | 18.3 | 305 |

| 18 | 19 × 0.23 | 0.33 | 1.81 | 23.2 | 305 |

| 20 | 19 × 0.20 | 0.33 | 1.61 | 36.7 | 305 |

| 20 | 1 × 0.80 | 0.33 | 1.46 | 35.2 | 305 |

| 22 | 19 × 0.16 | 0.33 | 1.46 | 59.4 | 610 |

| 22 | 1 × 0.65 | 0.33 | 1.31 | 56.4 | 610 |

| 24 | 7 × 0.20 | 0.33 | 1.26 | 94.2 | 610 |

| 24 | 1 × 0.50 | 0.33 | 1.16 | 89.3 | 610 |

| 26 | 7 × 0.16 | 0.33 | 1.14 | 150 | 610 |

| 26 | 1 × 0.40 | 0.33 | 1.06 | 143 | 610 |

| 28 | 7 × 0.12 | 0.33 | 1.02 | 239 | 610 |

| 28 | 1 × 0.32 | 0.33 | 0.98 | 227 | 610 |

| 30 | 7 × 0.10 | 0.33 | 0.96 | 381 | 610 |

| 30 | 1 × 0.254 | 0.33 | 0.914 | 361 | 610 |

Description

What is Fiberglass Braided Silicone Wire?

Silicone wires with an additional fiberglass braid layer are engineered as single conductor wires specifically for high-temperature settings. These hook-up wires are tailored to supplant the conventional wires with plastic or rubber insulation in scenarios where elevated temperatures are prevalent.

The silicone insulation jacket is a key feature of these wires, offering robust protection. The outer fiberglass braid adds another layer of defense, shielding the wire strands and the silicone layer from the stress of high temperatures. This braiding is not only effective against heat but also guards against physical abrasions.

These wires excel in applications demanding high mechanical resilience. They are perfectly suited for use in internal wiring of a variety of equipment such as lamps, instruments, control panels, and distributors. The fiberglass braid fortifies the silicone insulation against mechanical damage, ensuring durability and longevity. Moreover, these wires are halogen-free and demonstrate impressive resistance to heat.

The combination of silicone rubber insulation with fiberglass braid results in a high-temperature cable that boasts remarkable resistance to both high and low temperatures. It excels in electrical insulation performance and shows superior chemical stability. The cable is designed to resist high voltage, withstand aging, and has an extended service life. Its flexibility and ease of installation make it a preferred choice in various applications.

These cables find widespread use in lighting fixtures, household appliances, electrical and thermal devices, instrumentation, and motor wiring. They are especially suited for high-temperature environments typical in electronic devices, lamps, and burners, thanks to their durability and resistance to extreme conditions.

Why Fiberglass Braided Silicone Wire is better?

Injecting a dash of complexity into silicone wires through the infusion of glass fiber ushers in an era of performance upgrades, a cacophony of advantages echoing through the wire landscape.

- Frostbite-Defying Cold Resistance: Silicone braided wire, now imbued with the enigmatic essence of glass fiber, stands defiantly against the chill with an otherworldly 80% surge in cold resistance. This rebellious increase catapults these wires into a realm where icy temperatures merely serve as a backdrop to their resilient conductivity.

- Thermal Tenacity Beyond Norms: Temperature resistance takes on an avant-garde persona in the world of silicone braided wire, fortified by the enigmatic fibers of glass. A whopping 60% augmentation in thermal endurance propels these wires into domains where scorching heat is but a gentle caress. Unrivaled and unyielding, they redefine the benchmarks for thermal resilience.

- Chronicles of Anti-Aging Grandeur: The narrative of silicone braided wire with glass fiber infusion unfolds as an epic saga of anti-aging longevity. A celestial glow surrounds the average lifespan, eclipsing the mundane with a saga that spans more than 15 years. These wires embark on a timeless journey, defying the relentless march of time.

- Elasticity Symphony and Bending Resilience Ballet: Silicone braided wire, now a virtuoso in the symphony of elasticity, pirouettes through challenges with balletic bending resistance. The duet of softness and strength is played out in harmony, rendering these wires adaptable to the capricious climates that dot the tapestry of diverse environments.

The marriage of silicone and glass fiber is not a mere dalliance; it is a cosmic collaboration that births wires with a metamorphic allure. As the wires traverse the realms of cold, withstand the fiery touch of temperature extremes, craft an anti-aging odyssey, and dance through the rigors of varied climates, they emerge not just as conductors of electricity but as maestros orchestrating a symphony of performance.

Silicone Wire with Fiberglass Braid

Silicone Wire Ensemble with Fiberglass Braided Intricacies, a symphony of Styles and UL-coded Ballads, dances across the stage with a cacophony of random sequences:

Harmonizing in Style UL3070, an overture of Hook-up Wire cascades into the playful melodies of Style UL3074 and the rhythmic beats of Style UL3075. The crescendo reaches a peak with the flamboyant ululations of Style UL3098, spiraling into the intricate arrangements of Style UL3099.

Styles UL3100, UL3101, and UL3113 join the ensemble, each adding a unique timbre to the eclectic mix. A blaze of high temperatures is kindled with Style UL3125 and UL3126, as the wires entwine in a passionate embrace.

UL3127, UL3128, and the scorching fervor of Style UL3144 step into the limelight, creating a tapestry of High Temperature Wires. The symphony continues with the sizzling styles of UL3145, UL3172, and the sassy notes of UL3207.

UL3208, UL3209, and UL3210 join the dance, swinging through the temperatures with flair. UL3304 and UL3318 waltz in, their high-temperature elegance leaving an indelible mark.

UL3487, UL3513, and the magnetic charm of UL3561 fuse into the wire ballet, leading to the grand finale of Styles UL3605. The curtain falls, leaving the audience in awe of the diverse and unpredictable melodies woven by the Silicone Wire Ensemble with Fiberglass Braided enigma.