Car Wiring Harness Terminal Wires For Automotive

Car Wiring Harness Terminal Wires For Automotive

Item Number:Car Wiring Harness Terminal Wires For Automotive

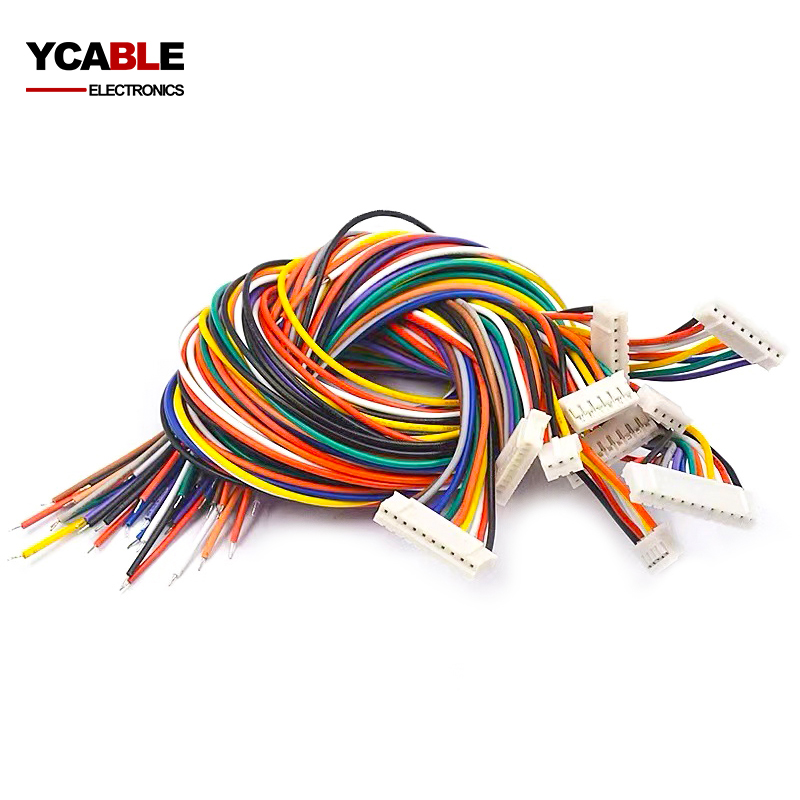

- Pin:: 2p,3p, 4p, 5p, 6p, 7p, 8p, 9p, 10p, 11p, 12p

- Connector:: According to customer's request to produce

- Type:: Same direction/Opposite direction

- Color:: Custom

- Length:: Custom

- Wire Gauge:: Custom 26AWG 28AWG 24AWG 22AWG 20AWG 18AWG

- Service:: OEM;Custom

Environmental Specifications:

Environmental Space – Non-plenum

Flame Test Method – CMR

Installation Temperature – 0 °C to +105 °C

Operating Temperature – -20 °C to +105 °C

Temperature Rating – 75 °C

General Specifications:

Wiring Harness Type

Car Wiring Harness Terminal Wire For Automotive

Pin, quantity

Custom

Cable Component Type

PE, PVC, Horizontal

Conductor Gauge, singles

30AWG-0AWG

Conductor Type, singles

Solid/Stranded

Characteristics:

- Enhanced protection against crosstalk and system noise.

- There are many brands sold on the market, so everyone must choose a large brand to ensure the quality

- Suitable for car wiring harness

Automotive Terminal Wire Harness For Car.

Categories

Car Wiring Harness Terminal Wires

| Electrical Specifications | |

| ITEM | Car Wiring Harness |

| Terminal Pin | 2-24Pin |

| Wire Size, maximum | 30AWG-0AWG |

| Color | Custom |

| Cutting and Striping | OEM |

| Transmission Standards | ANSI/TIA-568-C.2 CENELEC EN 50288-6-1 ISO/IEC 11801 Class E |

| Dielectric Strength, minimum | 1500 Vac 2500 Vdc |

Description

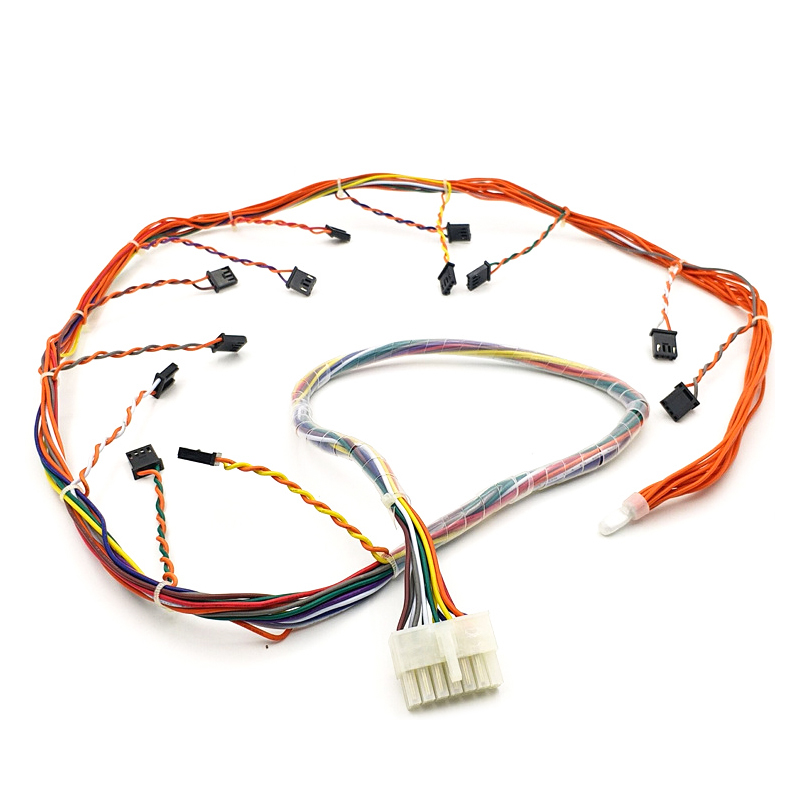

What is a car wire harness for automotive?

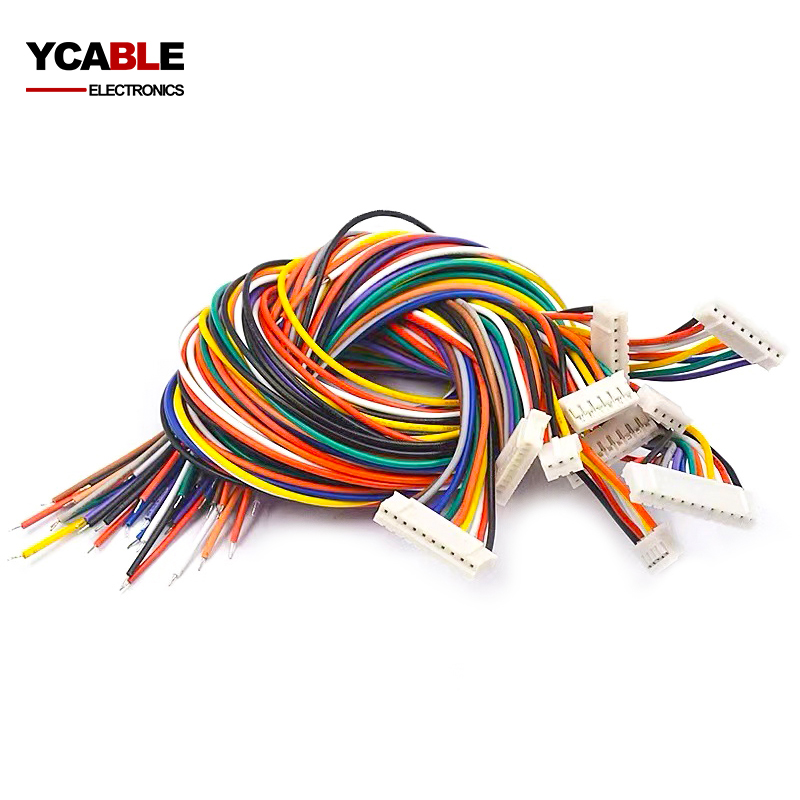

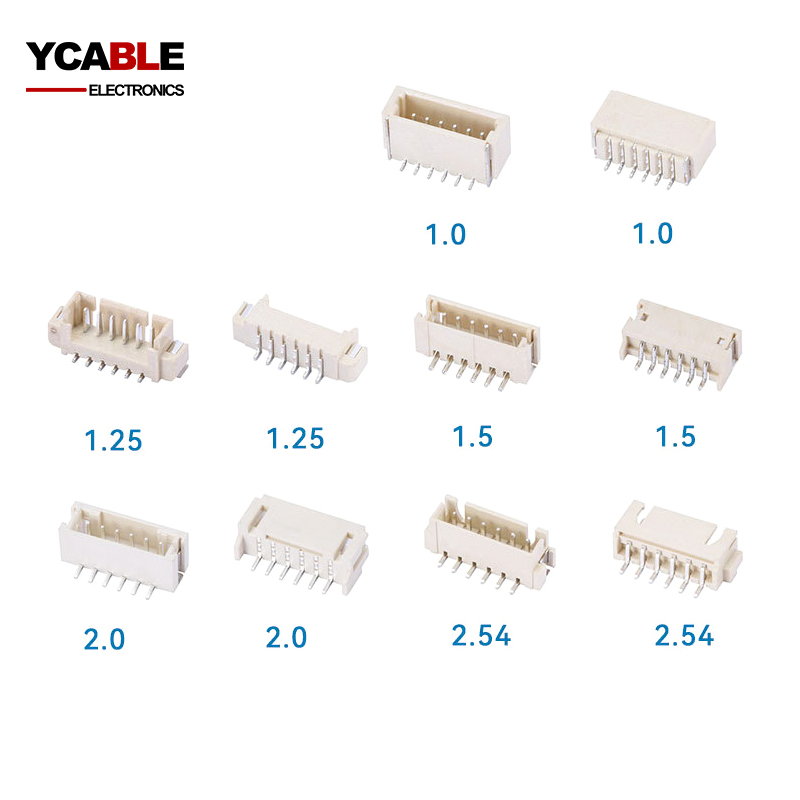

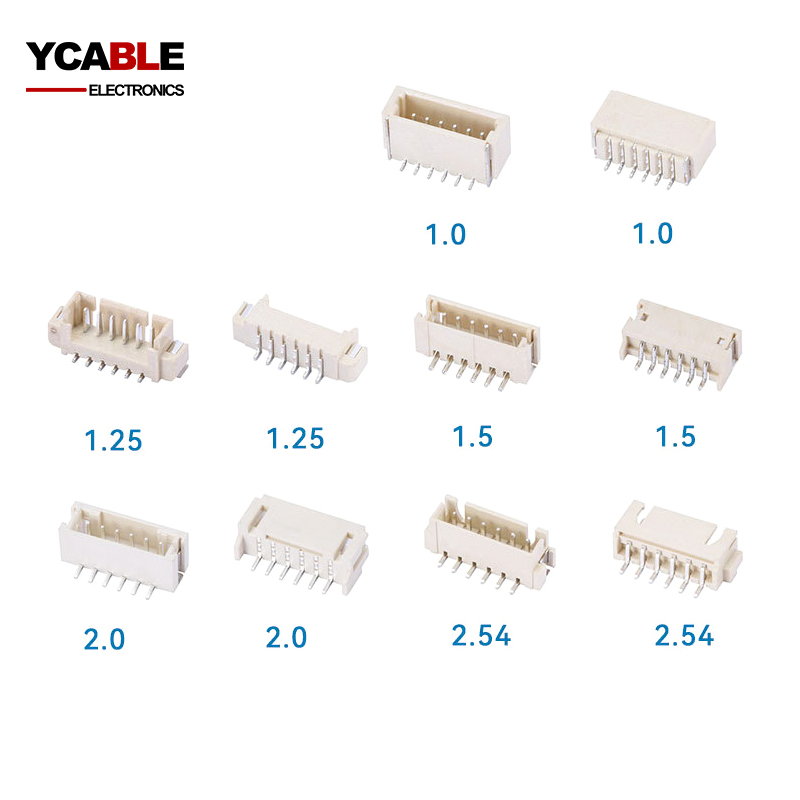

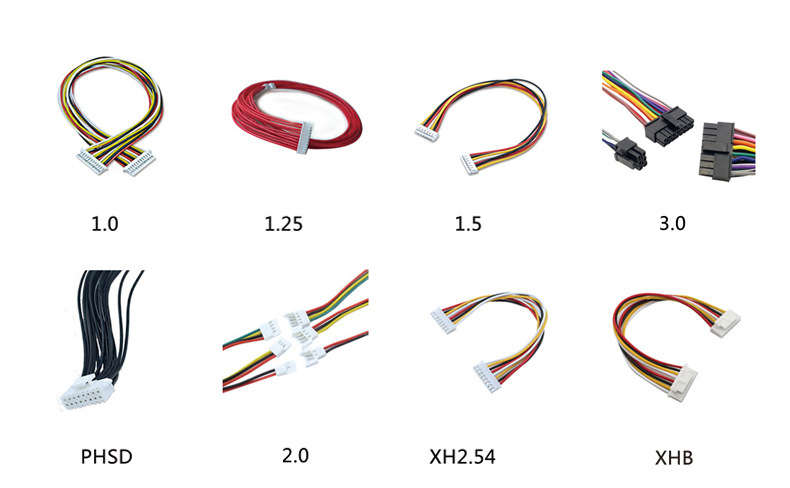

Car wiring harness terminal wire, also known as wiring harness assembly, can be arbitrarily selected for the number and spacing of wires, making wiring more convenient, greatly reducing the volume of electronic products, reducing production costs, and improving production efficiency. Car wiring harness terminal wires are most suitable for data transmission cables between mobile components and motherboards, between PCB boards and PCB boards, and in electrical equipment. They are one of the most common automotive wiring harnesses. Common terminal wire specifications include 0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 1.5mm, 2.0mm, 2.54mm, and various spacing flexible cable cables, which are widely used in practical life,

The uses of automotive terminal wires include:

- It is an indispensable system level component in automotive electrical appliances.

- Provide and distribute power to various electrical systems as a medium for signal transmission between components. For example, to power on the headlights, they need to be connected to the battery or generator through a wiring harness to form a power circuit.

- In order to light up the vehicle lights, the electrical controller (BCM) must recognize the intention of the control system to turn on the combination switch of the vehicle lights. The combination switch and BCM also require signal interaction through terminal wires.

- The automotive terminal wire is composed of wires, connectors, wire harness sheaths, wire harness clamps (clips, rubber parts, wire harness brackets, etc.), and related accessories,

What is Terminal Wire?

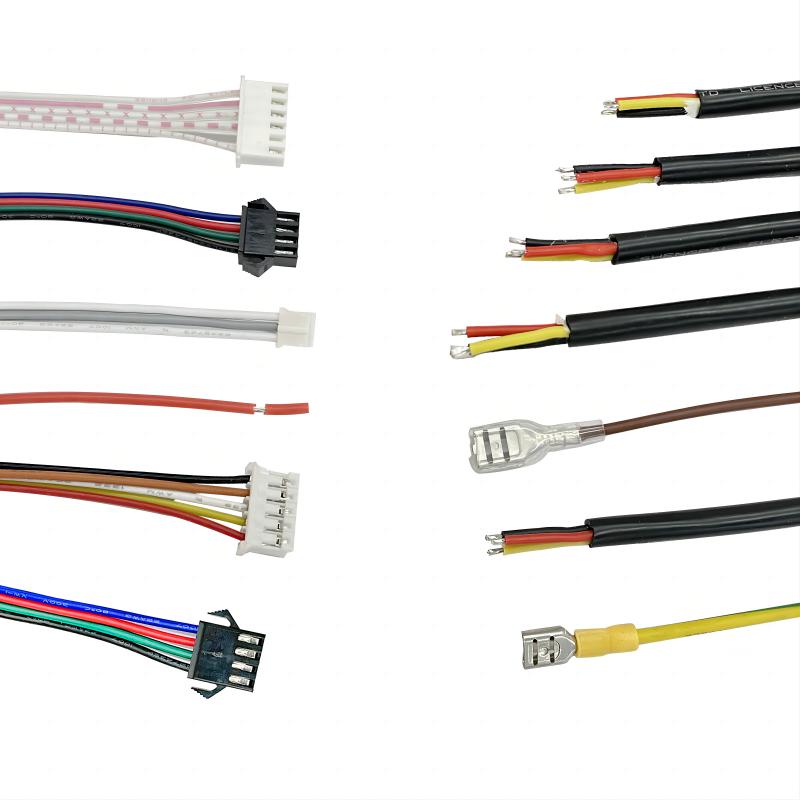

Terminal wires and connectors form a diverse group of electrical wire connectors, crucial for terminating or connecting wires to electrical systems. Their variety includes ring terminals, butt splices, wire caps, ferrules, fork terminals, pin terminals, among others, available in different insulation styles. At YCABLE ELECTRONICS, we utilize crimp connectors and other electrical connector types. When choosing wire terminals, consider factors like waterproofing, vibration resistance, and temperature tolerance to determine the best type for your needs.

Our inventory at YCABLE ELECTRONICS includes a wide range of terminal wires and connectors to suit various requirements. We stock an extensive selection to ensure you find the right part for your specific task.

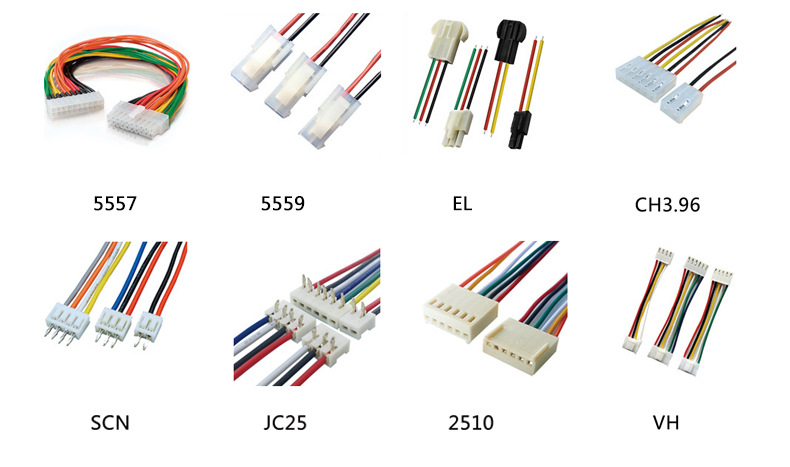

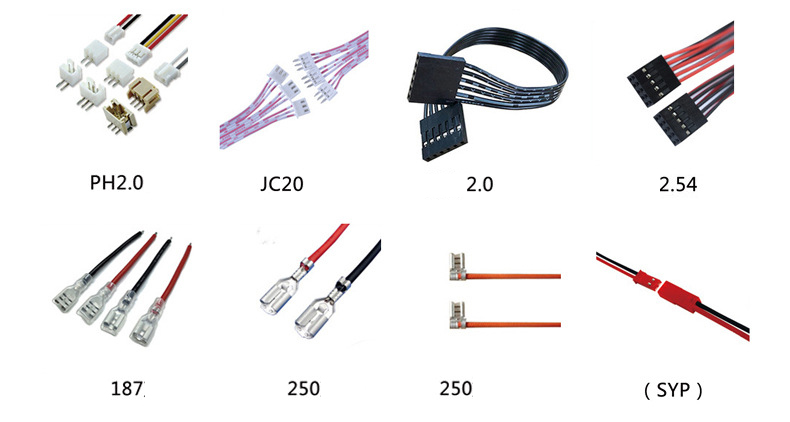

Types of Connectors and Their Uses:

- Environmentally Sealed Connectors: Ideal for harsh conditions, these connectors are field serviceable, allowing for easy disconnection, modification, and reconnection, often used in industrial settings.

- Splices: Used for joining wires, available in different styles for various tasks. Regular butt splices are suitable for wire replacement, while step-down butt splices are used for connecting wires of different gauges. The choice of insulation should be based on the environmental conditions the connection will face.

- Ring Terminals: Known for their secure connection, these terminals fit over a stud and are locked in place with a nut. They are popular for their durability and ease of installation, and can be used to connect multiple wires to a single terminal or multiple terminals to a stud.

- Fork Terminals: Available in locking and flanged versions, fork terminals are useful for connections that require frequent adjustments. They are designed to combat loosening due to vibration, ensuring a stable connection.

- Pin Terminals: Ideal for use with compression-type terminal blocks, especially for stranded wires. Pin terminals consolidate the strands into a single solid wire, preventing damage from screw tightening.

- Lugs: Similar to ring terminals but more durable, lugs are suited for larger gauge wires or harsh environments where corrosion is a risk. Made from high-quality copper, they offer excellent conductivity.

- Battery Posts: Designed for connecting loads to batteries, these connectors are made from 131 contact copper for high conductivity. They often require specialized tools for crimping and are electro-plated with tin to prevent corrosion. Additional protection can be provided with a boot covering.

What is the difference between a terminal and a connector?

Firstly, Understanding the Conceptual Distinctions between Connector and Terminal

Connector: This is a component frequently encountered by electronic engineering technicians, typically referring to electrical connectors. It serves as a device for connecting two active devices, facilitating the transmission of current or signals.

Connectors also denote positioning connectors for electronic circuits, comprising two parts: the plug-in and the connector, which are generally separable. The key distinction between a switch and a connector is that a switch changes the state of contact pairs to alter the connected circuit, while a connector only has two states: insertion and removal. Unlike switches, standard power connectors don’t facilitate circuit conversion on their own and maintain a fixed correspondence between contact pairs.

Terminal: This accessory is utilized for electrical connections and is categorized under connectors in industrial terms. Terminals simplify wire connections and consist of a metal sheet encased in insulating plastic, with holes at each end for wire insertion. Various types of terminals include WUK terminals, European terminal series, plug-in terminals, and others.

Secondly, Differentiating the Scope of Connectors and Terminals

The term "Connector" encompasses a broad category, within which terminals are a subset. Connectors are used for wire-to-wire, wire-to-board, and wire-to-box connections, often grouped together in practical usage.

Terminals are a part of the connector category. The term "Connector" is broad and generally includes both the housing (usually plastic for protection) and the terminal (metal for conductivity).

In the electrical field, connectors and terminals have distinct uses:

Connectors are typically quick-connect devices that can be engaged with a simple plug or twist, not requiring tools.

Terminals, on the other hand, usually need tools like screwdrivers or cold press pliers for connection, and are commonly used for power input and output.

Thirdly, Practical Applications of Connectors vs. Terminals

Connectors represent a specialized sector within electronic components, primarily used for circuit connections. Given the omnipresence of line connections in industrial production, connectors have a vast range of applications across various industries.

There are numerous types of connectors, such as rectangular connectors, mil dtl 38999 circular connectors, stepped connectors, etc. Terminals are a kind of rectangular connector and have a more specific use, typically in electronics for internal and external wiring of PCBs, printed boards, and power distribution cabinets.

The application scope of terminals is expanding, with various types emerging. Besides PCB board terminals, widely used types include hardware terminals, nut terminals, spring terminals, and others. In the power sector, specialized terminal strips and boxes are employed, featuring single-layer, double-layer, current, voltage, common, breakable terminals, and more.

In summary, "connectors" and "terminals" represent distinct applications within a shared conceptual framework, differentiated based on their specific practical uses.

How to determine the defect of the automobile terminal wire?

Terminal wires are used to facilitate the connection of internal wires of various motor appliances. There are holes at both ends that can be pierced, and the number and spacing of wires can be freely selected, making the connection more convenient and maintenance simpler, greatly reducing the volume and production cost of electronic products, and improving production capacity. The general specifications are 0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.5mm, 2.0mm, 2.5mm, and 2.54mm. Currently, various spacing terminal wires and electronic wires are widely used for the connection between printer heads and motherboards, as well as the signal transmission and board connection of speakers, motors, speakers, audio systems, LCD appliances, fax machines, and various optical disk machines. In modern electrical equipment, it is almost ubiquitous, and the quality of terminal wires directly affects the quality of products. The following are some points for judging poor terminal wiring.

During the quality inspection process of terminal wires, due to visual fatigue of the human eye, it is inevitable to encounter assembly position errors, leading to the outflow of defective products. However, the wire sequence conduction detector can achieve a 100% yield rate and a working power of more than 5 times that of labor, so you don't have to worry about the outflow of defective products to ensure product quality, greatly improve the working power of the enterprise, save labor, reduce production costs, and give the enterprise a greater price advantage and establish an excellent brand image.

Attention should be paid to judging poor terminal wires:

- 1. The joint must be in close contact and the wire core and PVC cannot be seen; After crimping the wire core and PVC, both must be clearly visible; The wire core must be exposed by 0.2mm-1mm (different terminal specifications, different exposed wire core lengths). After PVC crimping, the joint must be in a straight line, with both ends symmetrical. Otherwise, it will be considered a defective product.

- 2. The stripping length is too short; Excessive twists and turns; Tailings are too long; They are also judged as defective products.