PVC Hook Up Wire

PVC Hook Up Wire

Item Number:PVC Hook Up Wire

- Model: PVC Hook Up Wire

- Size: 0AWG - 30AWG

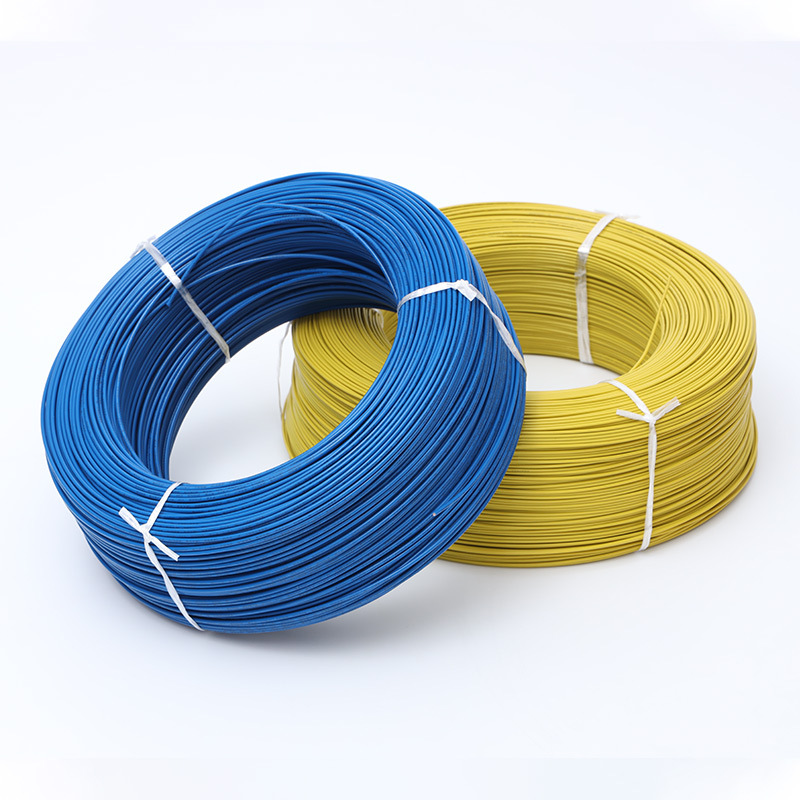

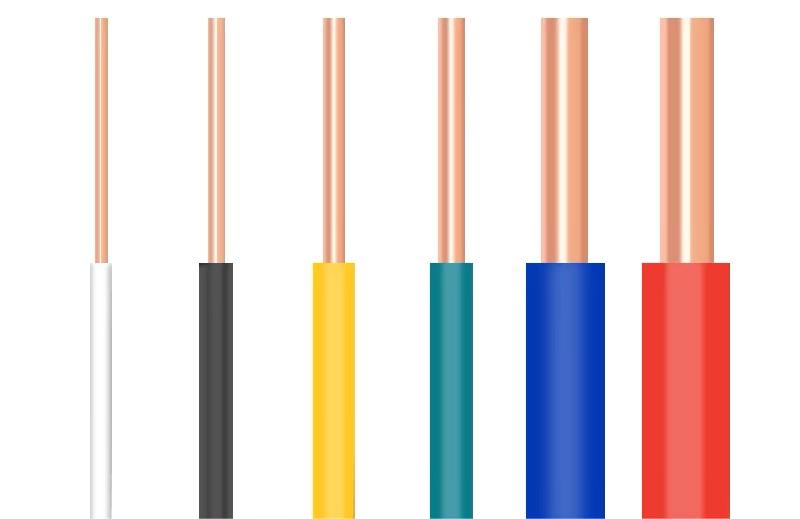

- Color: White/Blue/Black/Gray/Custom

- Insulation: PVC

- Shield: None

- Jacket: None

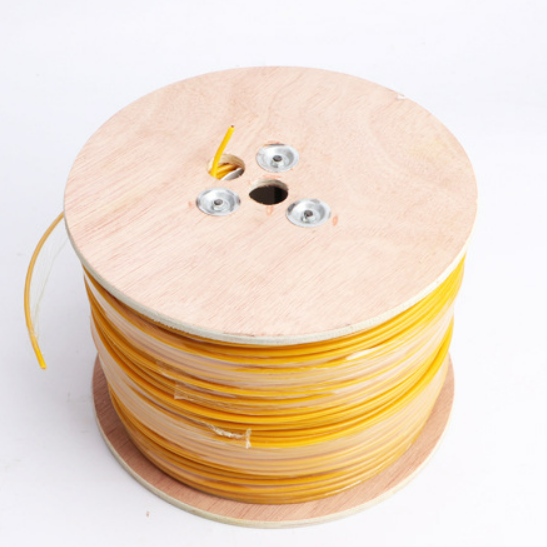

- Packing: 305M(1000FT)/610M/1000M/Custom

- OD: -

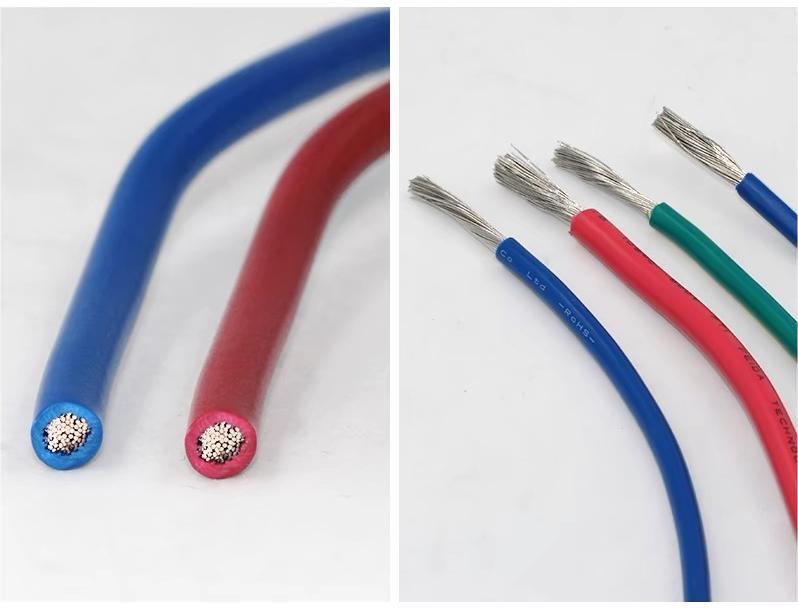

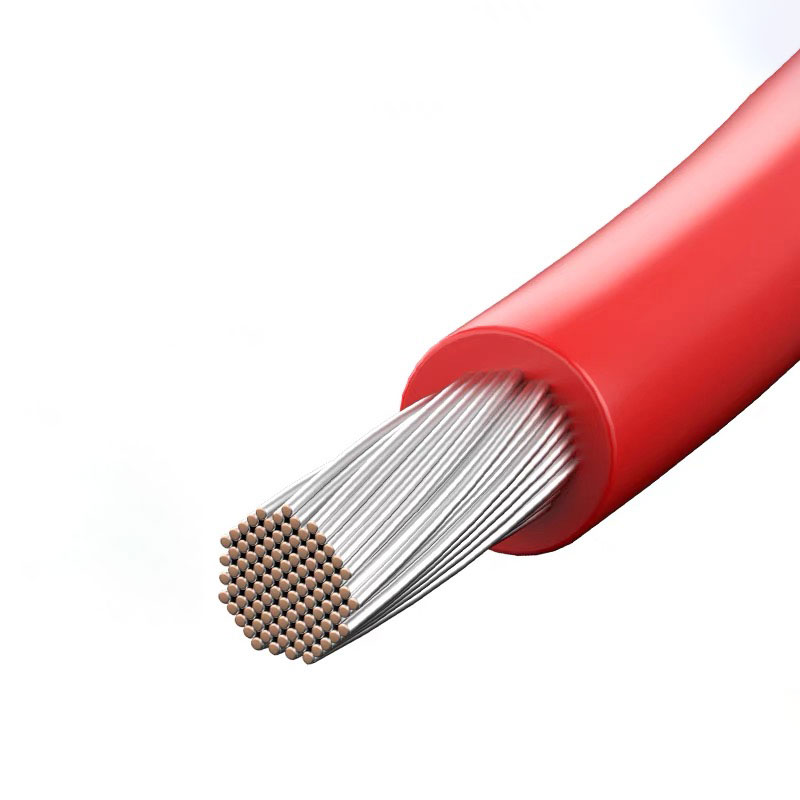

- Conductor Material: Bare Copper, tinned copper, silver plated copper

- Drain wire: None

Environmental Specifications:

Environmental Space – Non-plenum

Flame Test Method – CMR

Installation Temperature – 0 °C to +105 °C (+32 °F to +140 °F)

Operating Temperature – -20 °C to +105 °C (-4 °F to +140 °F)

Temperature Rating – 75-105 °C

General Specifications:

Cable Type

PVC hook up wire

Conductor, quantity

1

Cable Component Type

PVC

Conductor Gauge, singles

0AWG-28AWG

Conductor Type, singles

Solid/Stranded

Characteristics:

- Operating Temperature:

- 40 to 105°C (-40 to 221°F)

- UL AWM 1569

- 40 to 90°C (-40 to 194°F)

- CSA TR-64

- 40 to 80°C (-40 to 176°F)

300V Voltage Rating

Stranded or Solid Tinned Copper Conductor

Color-Coded PVC Insulation

PVC-coated connection cable stands as a PVC-shrouded, 300 Volt graded solitary conductor apparatus wire, adhering to ROHS standards. Its surface is tinned for oxidation reduction and is procurable in both solid and stranded forms across various hues. This PVC-encapsulated connection wire finds its application within sealed electronic apparatuses. Usual utilization spans control units, measurement devices, computing systems, commercial apparatuses, and appliances necessitating direct wiring connectivity

Categories

PVC hook up wire

| Electrical Specifications | |

| ITEM | PVC hook up wire |

| Size | 0AWG-30AWG |

| Material | PVC |

| Mutual Capacitance | 5.6 nF/100 m @ 1 kHz |

| Nominal Velocity of Propagation (NVP) | 69 % |

| Operating Frequency, maximum | 300 MHz |

| Operating Voltage, maximum | 80 V |

| Transmission Standards | ANSI/TIA-568-C.2 CENELEC EN 50288-6-1 ISO/IEC 11801 Class E |

| Dielectric Strength, minimum | 1500 Vac 2500 Vdc |

Description

What is PVC Hoop Up Wire

PVC hoop up wire, encapsulating a copper core enveloped by insulation, manifests in two avatars: the solitary-solid, a monolithic copper filament, or the composite-stranded, weaving together slimmer filaments into a robust gauge. Engineered primarily for operations demanding low voltage and amperage, such as nestled within electronic apparatus, this copper vein also traverses the domains of vehicular and maritime engineering, thermal devices, command interfaces, structural ventures, domestic machines, amidst varied realms both vaulted and vast. Its fabrication often aligns with specific UL and MIL-spec mandates, ensuring a broad adaptability.

Perks of PVC Hoop Up Wire

Sprawling across a spectrum of devices, utilities, and conveyances, PVC hoop up wire unfurls numerous perks rendering it a cornerstone for projects:

- Copper's prowess in electrical conduction remains unmatched.

- Copper strides ahead in thermal transference, only shadowed by silver.

- Its stoic resistance to corrosion, owing to minimal reactivity, slashes the frequency of expensive renewals.

- The ductility of PVC hoop up wire empowers easy manipulation, a quintessential trait for electrical layouts demanding nimble navigation.

- A PVC shroud encases the wire, fortifying it against physical abrasions, chemical intrusions, et al.

Electing the Ideal PVC Hoop Up Wire

Confronted with a plethora of PVC hoop up wire varieties might seem formidable. Our Resources enclave, replete with a PVC Hoop Up Wire Data Chart and an assortment of Ampacity Charts, is at your disposal to aid in an astute selection. Focal points should include specifics, applicative spheres (electronics, construction, maritime, automotive), dimensions, alongside voltage, temperature, conductor, and insulation criteria. For an expanded insight, we're a call away.

Common UL PVC hook up wire types

| UL1007 | 300V |

| UL1015 | 600V |

| UL1061 | Stranded |

| UL1571 | Solid |

| UL1051 | |

| UL1430 |

Stranded vs. Solid PVC Hoop Up Wire

Whether the predilection is towards stranded or solid PVC hoop up wire, each genre pledges compliance with our delineated standards and grades.

Stranded wire, known for its suppleness, better withstands recurrent flexing compared to its solid counterpart. Conversely, solid wire, with its inherent rigidity, is tailored for resilience against the elements, harsh environmental contexts, and perpetual displacements, predominantly in exterior applications.

Tailoring Your PVC Hoop Up Wire

Acknowledging the pivotal role of your venture, we proffer custom solutions ranging from coil to trifilar winding, wire acquisition, and processing, ensuring the wire you receive dovetails with your requisites. In quest of bespoke lengths, stripped or terminated wires, or a wire ensemble? Engage with us. Peruse our custom wire services portal or procure a bespoke estimate sans cost by clicking "Add to Quote" on any product delineation.