10 GA High Strength Tracer Wire

10 GA High Strength Tracer Wire

Item Number:

- Model: Tracer Wire

- Size: 10GA, 10AWG, 10Gauge

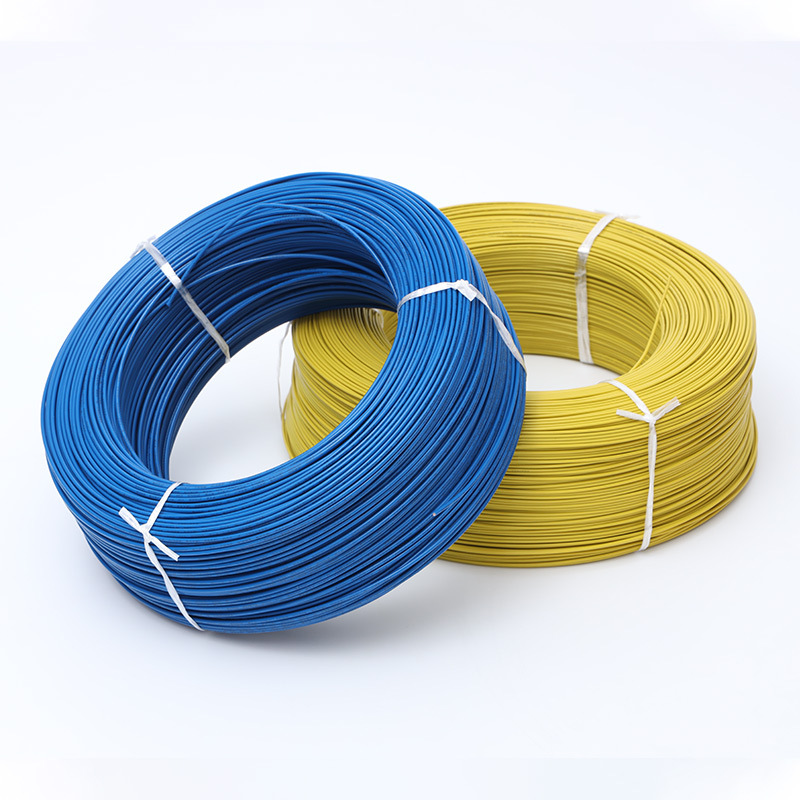

- Color: Yellow, Orange, Blue, Custom

- Insulation: HDPE, HMWPE

- Shield: None

- Jacket: None

- Packing: 2500FT/Wooden Reel

- OD: 30mils, 45mils, Custom

- Conductor Material: CCS

- Drain wire: None

General Specifications:

Cable Type

Tracer wire

Pairs, quantity

Single Core

Cable Component Type

Horizontal/HDPE/HMWPE

Conductor Gauge, singles

10AWG/10GA

Conductor Type singles

Solid

Characteristics:

- Strength & Flexibility: Strong enough for underground use while being flexible for easier handling during installation.

- Good Signal Performance: Adequate conductivity for efficient signal transmission over medium to long distances.

- Cost Efficiency: Lower material cost compared to solid copper wire.

- Versatility: Suitable for a wide range of utility tracing applications.

- Corrosion Protection: Copper cladding ensures resistance to environmental factors, extending the life of the wire.

In general, the 10GA CCS tracer wire is a reliable, cost-effective, and durable solution for underground utility locating, offering long-term performance and enhanced safety in diverse applications

Categories

None

| Specifications | |

| Item | 10GA tracer wire |

| Conductor Type | Copepr Clad Steel/CCS |

| Average Break Load | 452 LBS |

| Minimum Elongation | >10% |

| Nominal Copper Thickness (% of Diameter) | 3 % |

| Nominal Copper Weight | 13% |

| Minimum Tensile Strength | 67,000 psi |

| Nominal DC Resistance (ohms/1000 ft.) | 7.564 |

| Temper | Dead Soft Annealed (DSA) |

Description

The benefits of 10GA CCS tracer wire

10GA CCS (Copper Clad Steel) tracer wire offers several advantages over thinner gauges like 12GA tracer wire, making it a suitable choice for certain applications:

Increased Strength:

- A 10GA wire is thicker and stronger than 12GA, providing greater tensile strength. This makes it more resistant to physical damage during installation or from environmental stress, such as soil movement, shifting ground, or accidental impacts.

Longer Lifespan:

- Due to its increased thickness, 10GA CCS wire is more durable and can withstand harsher conditions. It is less prone to breaking or stretching over time, making it a better choice for high-stress installations or areas with heavy traffic.

Improved Signal Integrity:

- The thicker wire can handle higher current or voltage levels, which can improve signal transmission over longer distances. This is particularly useful when tracing utilities over larger areas or through complex underground environments.

Better Resistance to Corrosion:

- Like all CCS wire, the copper coating on the steel core offers corrosion resistance. With a thicker wire, the wire is generally more robust, providing a longer-lasting solution in environments prone to moisture or chemicals.

Greater Compatibility with Larger Utilities:

- In applications where larger utilities (such as larger water or gas lines) need to be traced, 10GA wire may provide the necessary durability and signal strength. It can handle the increased demands of higher-power tracing equipment or more extensive networks.

Higher Pulling Strength:

- 10GA tracer wire has better pulling strength, which can be crucial when installing the wire over long distances or through challenging terrains. The thicker wire is less likely to break during installation.

When to Use 10GA CCS Tracer Wire:

- In environments with heavy soil, frequent excavation, or potential damage from construction equipment.

- For long-distance installations or complex layouts requiring robust signal transmission.

- In high-traffic areas or locations with physical risks to the wire.

While 10GA CCS wire tends to be more expensive and harder to install than 12GA wire, its advantages in strength, durability, and performance make it a good choice for more demanding applications.

Application scenarios of 10GA CCS tracer wire

10GA CCS (Copper Clad Steel) tracer wire is typically used in scenarios where the benefits of increased strength, durability, and signal integrity are essential. Here are some common application scenarios:

High-Stress Environments

- Heavy Traffic Areas: For installation near roadways, highways, or locations with frequent construction and heavy equipment traffic. The extra strength of 10GA wire helps prevent breakage or damage from mechanical impact.

- Construction Zones: Areas where digging, excavations, and soil disturbances are common, which might put additional strain on tracer wires.

Long-Distance Installations

- Long Utility Runs: When tracing utilities over long distances (e.g., large water or gas pipelines), 10GA wire provides better signal transmission without significant voltage drop, ensuring accurate detection over greater distances.

- Complex Installations: In sprawling industrial or commercial developments where the utility lines are spread out or cross various terrains.

Harsh Soil Conditions

- Rough or Rocky Terrain: Areas with rocky soil or rough, abrasive conditions where a thicker wire can better withstand damage.

- High Moisture or Corrosive Environments: While CCS wire is corrosion-resistant, the thicker gauge offers extra protection against long-term exposure to moisture or chemicals, making it suitable for wetland areas or coastal regions.

Critical Infrastructure

- Utility Critical Areas: For applications like gas or water distribution systems where uninterrupted service and accurate tracing are essential. The higher strength and durability of 10GA ensure it remains intact and functional over time.

- High-Pressure Gas Lines: When tracing gas lines, particularly those with high pressure or large diameter, a stronger wire like 10GA ensures reliable functionality.

High-Demand Tracing Applications

- High-Power Tracing: For use with advanced locating equipment that might require a stronger, more robust tracer wire to handle higher power or signal levels, ensuring accurate utility location.

- Complex Utility Networks: In environments with multiple utility lines running in parallel, where durability and signal clarity are crucial for preventing false readings or missed locations.

Industrial and Remote Locations

- Industrial Sites: Large factories or industrial sites where utilities are often deep underground and subject to physical stresses from equipment, machinery, or building modifications.

- Remote or Hard-to-Reach Areas: In rural or remote areas with difficult terrain or limited access, where installation and maintenance might be challenging and the wire needs to endure harsh conditions.

Rehabilitation or Replacement of Existing Systems

- Upgrades to Existing Infrastructure: When replacing or upgrading old tracer wires in aging infrastructure, 10GA CCS wire may be chosen for its added strength and longevity, reducing the need for frequent replacements.

High-Volume and High-Risk Projects

- Municipal or Large-Scale Utility Projects: For city-wide or large-scale infrastructure projects, where multiple utility lines are involved, and it’s crucial to ensure long-term durability and reliability of tracer systems.

In summary, 10GA CCS tracer wire is ideal for high-stress, high-demand applications where greater strength, longer signal transmission range, and durability are essential. Its ability to withstand physical damage, corrosion, and harsh environmental conditions makes it a preferred choice for critical or challenging installations.