Custom Ethernet Patch Cables

Custom Ethernet Patch Cables

Item Number:Custom Ethernet Patch Cable

- Model: Custom Ethernet Patch Cables CAT5 CAT6 CAT7 CAT8 Patch Cord+RJ45

- Size: 22AWG~26AWG Soild(0.46mm-0.51mm)/Stranded/Custom

- Color: White/Blue/Black/Gray/Custom

- Insulation: PE

- Shield: Unshielded/shield/Custom

- Jacket: PVC/FR-PVC/LSOH/Custom

- Packing: Custom

- OD: 5.2mm/Custom

- Conductor Material: OFC/Cu/Copper/CCA/Copper Clad Aluminum/CCS

- Drain wire: None/Custom

Environmental Specifications:

Environmental Space – Non-plenum

Flame Test Method – CMR

Installation Temperature – 0 °C to +60 °C (+32 °F to +140 °F)

Operating Temperature – -20 °C to +60 °C (-4 °F to +140 °F)

General Specifications:

Cable Type

Custom Ethernet Patch Cables CAT5 CAT6 CAT7 CAT8 Patch Cord+RJ45

Pairs, quantity

4

Cable Component Type

Horizontal

Conductor Gauge, singles

24AWG/Custom

Conductor Type, singles

Solid/Stranded

Characteristics:

- The transmission speed is very fast. Compared to other types of network cables, the transmission speed of the Super Five network cables will be faster, reaching 10 Mbps.

- The manufacturing process is also very good, which can effectively reduce signal interference. Moreover, they are all made of copper wires twisted together, so the electrical conductivity is very good.

- There are many brands sold on the market, so everyone must choose a large brand to ensure the quality of the network cable.

- Suitable for indoor applications

In general, the network cable Patch cord has several advantages, such as well overall performance, high-cost performance, and relatively low difficulty in construction and maintenance. Choosing it will not disappoint you.

Categories

Custom Ethernet Patch Cables CAT5 CAT6 CAT7 CAT8 Patch Cord

| Electrical Specifications | |

| ANSI/TIA Category | Custom Ethernet Patch Cables CAT5 CAT6 CAT7 CAT8 Patch Cord+RJ45 |

| dc Resistance Unbalance, maximum | 5 % |

| dc Resistance, maximum | 9.38 ohms/100 m |

| Mutual Capacitance | 5.6 nF/100 m @ 1 kHz |

| Nominal Velocity of Propagation (NVP) | 69 % |

| Operating Frequency, maximum | 200 MHz |

| Operating Voltage, maximum | 80 V |

| Transmission Standards | ANSI/TIA-568-C.2 CENELEC EN 50288-3-1 ISO/IEC 11801 Class D |

| Dielectric Strength, minimum | 1500 Vac 2500 Vdc |

Description

Custom Ethernet Patch Cables Manufacturer

At YCABLE ELECTRONICS, we specialize in crafting Custom Ethernet Patch Cords tailored to your specific requirements. Our made-to-order Ethernet patch cables are fabricated in the USA using premium components. We provide a plethora of customization options, including various lengths, colors, and choices between booted and non-booted designs. Each of our custom Ethernet patch cables undergoes rigorous testing by Fluke, ensuring certification and top-notch quality. These tests include assessments for near-end crosstalk (NEXT) and return loss, and each cable is distinctively marked with a part number and individual serial number. We also cater to your bespoke labeling needs on one or both ends of the cable, ensuring they are ideal for critical network environments.

Our range of custom Ethernet patch cables encompasses various categories, including Cat 5E, Cat 5E Shielded, Cat 6E, Cat 6E Shielded, and Cat 6A Shielded. Additionally, we provide both plenum and riser rated jacket options to suit your specific installation needs. For environments that demand robust and enduring solutions, like outdoor or harsh conditions, we offer custom outdoor direct burial rated Ethernet patch cables in both Cat 5E and Cat 6 categories.

In more demanding scenarios such as outdoor events, military, industrial testing, or concerts, our Tactical & Rugged Deployable Custom Ethernet Assemblies are the go-to choice. On the other hand, our range of Stock Ethernet patch cables, available in Cat 5E, Cat 6, Cat 6A, Cat 7, and Cat 8, both shielded and unshielded, are excellent for installations where budget considerations are paramount. These cables come in various jacket diameters and strain relief boot styles to fit your specific Ethernet cable installation requirements.

Whether it's for connecting to routers, network servers, computers, or other hardware, our high-quality Ethernet Patch Cables meet industry standards and surpass patching performance requirements, including support for Power over Ethernet (PoE).

Our easy-to-use Configuration Tool helps you quickly identify and select the products you need. For any queries regarding our products or services, feel free to reach out to us.

Key Features of Our Ethernet Cable Categories:

- Cat 5e: Offers effective performance for most applications, with data transfer speeds up to one Gigabit per second at 100 MHz for distances up to 328 feet.

- Cat 6: Supports faster data transfer speeds up to 10 Gbps at 250 MHz, suitable for Gigabit Ethernet networks.

- Cat 6a: Ideal for long-term Gigabit Ethernet networks, supporting 10 Gbps transmission speeds up to 328 feet at 500 MHz.

- Cat 7: Recommended for smart home devices, providing up to 600MHz performance and superior noise resistance due to shielding.

- Cat 8: Designed for high-speed data centers, capable of handling 25G and 40G networks, and shielded to minimize crosstalk.

About Our Patch Cables:

- Custom Patch Cables: Customizable in length and type, these cables are built in the USA and designed for critical networks.

- In Stock Patch Cables: Ready for immediate dispatch, offered in a variety of colors and standard lengths.

- Additional Considerations:

- Booted vs. Non-Booted: Our custom booted cables feature easy-release tabs, providing extra strain relief at the connector.

- Stranded vs. Solid Conductors: Stranded conductor cables offer flexibility, while our plenum custom cables use solid conductors for installation in plenum spaces.

Understanding Plenum Rated Cables:

Plenum-rated cables are essential in spaces used for air circulation in heating or air conditioning systems, as per building codes. They must be fire-retardant with low smoke production.

Choosing the Right Cabling:

For 10-Gigabit Ethernet, Cat 6A cabling is recommended, particularly shielded types to minimize noise interference. When runs exceed 328 feet, switching to fiber optic cabling, like our custom-made, easy-to-install fiber assemblies, becomes necessary.

For any assistance or to explore our wide range of Custom Ethernet Patch Cords, please visit our website or contact us directly.

What Can YCABLE ELECTRONICS Offer You?

YCABLE ELECTRONICS, a prominent custom ethernet patch cord manufacturer, offers a versatile range of pre-made and custom-manufactured patch cables. Available in various lengths and colors, our offerings can be explored through the links at the top of our page.

Cat 3 or Category 3 Patch Cables: Once a standard in the early '90s, Cat 3 cables facilitated data transmission speeds up to 10Mbps. Today, while their use in computer industries has significantly dwindled, they still find some application in the telecommunications sector, particularly in 2 pair and 3 pair configurations.

Cat 5 & Cat 5e (Category 5, Category 5 Enhanced) Patch Cables: The demand for greater bandwidth and faster network speeds in the late '90s led to the evolution of Category 5 cabling. Initially, Cat 5 cables offered 100MHz at 100Mbps performance, but this standard was quickly superseded by Category 5 Enhanced (Cat 5e). Cat 5e patch cables boast enhanced capabilities, being tested for performance up to 350MHz at 1 Gbps.

Cat 6 or Category 6 Patch Cables: The Cat 6 standard, providing 200MHz bandwidth (double that of Cat 5), emerged to cater to the growing needs for bandwidth in streaming multimedia applications. Although the official standard is 200MHz, many manufacturers test their Cat 6 patch cables up to 550MHz at 1 Gbps. Cat 6 cables adhere to stringent manufacturing and channel requirements, ensuring a tight pair twist near the connector or jack for optimal performance. Every component in a Cat 6 network is held to high standards to maintain this level of performance. Some Cat 6 cables include a plastic spline for enhanced pair separation, while others achieve the necessary standards with tighter pair twists. Regardless of the specific construction method, meeting the Cat 6 standards is the critical factor.

At YCABLE ELECTRONICS, we understand the evolving needs of network infrastructure and provide high-quality, custom solutions to meet these demands. Whether you require standard or custom configurations, our diverse range of Ethernet patch cords is designed to deliver reliability and performance in various networking environments. For more information or to place an order, please visit our website or contact us directly.

Custom Ethernet Patch Cable Manufacturing Process

At YCABLE ELECTRONICS, our proficiency in cable production shines through our internal cable manufacturing process, ensuring the delivery of superior quality patch cables.

PHASE 1: Crafting Copper Cables

- Complex Wire Drawing Techniques: Our copper wire undergoes a meticulous wire drawing process. This involves pulling the wire through a die to slenderize its diameter while elongating its length, maintaining constant volume. The copper wire diameter transforms from a robust 2.6 mm to a slender 0.5 mm (10 AWG to 24 AWG), customized according to specific cable types such as 24 AWG for Cat5 and 23 AWG for Cat6e patch cables.

- Enhancing Flexibility through Annealing: Post-drawing, the wire is annealed to augment its flexibility. This involves heating the copper wire and then gradually cooling it. A brief immersion in water at 1000 degrees Fahrenheit ensures oxidation and corrosion prevention.

- Insulation Extrusion Process: Subsequently, the wire undergoes an insulation application process. We utilize high-density polyethylene, which is heated until it melts and then applied to the wire.

- Precise Diameter and Insulation Evaluation: Following insulation, we meticulously measure the wire's diameter and insulation, alongside assessing its electrical properties such as capacitance and resistance.

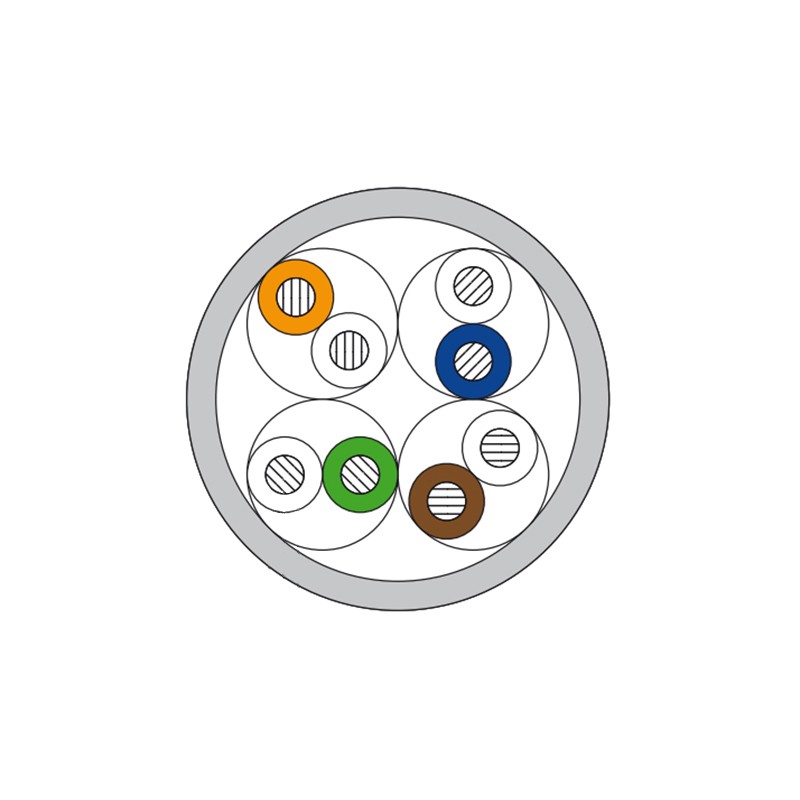

- Strategic Wire Twisting: The insulated wires are then methodically twisted into pairs. Each pair is given a distinct twist length to minimize interference and crosstalk.

- Formation of Cable Core: The twisted pairs are aggregated to form a multi-unit cable core. This core is intertwined to enhance flexibility and minimize electrical interference.

- Comprehensive Jacketing Process: The jacketing stage involves various procedures, including gel-filling and armoring, culminating in the production of the final cable wound onto wooden reels.

PHASE 2: RJ45 Patch Cable Termination

- Cable Preparation: The cables are precisely cut into standardized lengths and outfitted with RJ45 modular plugs at both ends, adhering to industry norms.

- Adherence to EIA/TIA T568B Standards: The internal conductor pairs are untwisted and arranged in compliance with the 568B standard, ensuring uniformity in the wiring process.

- Load Bar Utilization for Enhanced Alignment: Particularly in Cat 6 and higher categories, a load bar is employed to align thicker wires within the RJ45 connector, effectively reducing crosstalk.

- Securing the RJ45 Connector: Wires are carefully inserted into the RJ45 connector, ensuring each wire aligns with the corresponding gold pin.

- Final Crimping for Stability: The final step is the crimping of the cable and connector, solidifying the patch cable’s integrity.

Quality Assurance and Shipping Protocols

- Comprehensive Electrical Testing: We conduct exhaustive electrical tests, including continuity and core-to-sheath evaluations, to assure the cables withstand high-voltage surges and maintain electrical integrity.

- Final Inspections and Packaging: Prior to packaging, each cable undergoes a rigorous inspection for physical and electrical quality, ensuring only the best products are dispatched.

At YCABLE ELECTRONICS, we are not only committed to producing exceptional patch cables but also take significant measures to ensure environmental safety in our processes. We employ a stringent quality control protocol that encompasses raw material inspection, production monitoring, and final product assessment, guaranteeing that each cable meets our high standards of excellence and sustainability.