Custom Fiber Optic Patch Cable Optical Fiber Patch Cord Manufacturers

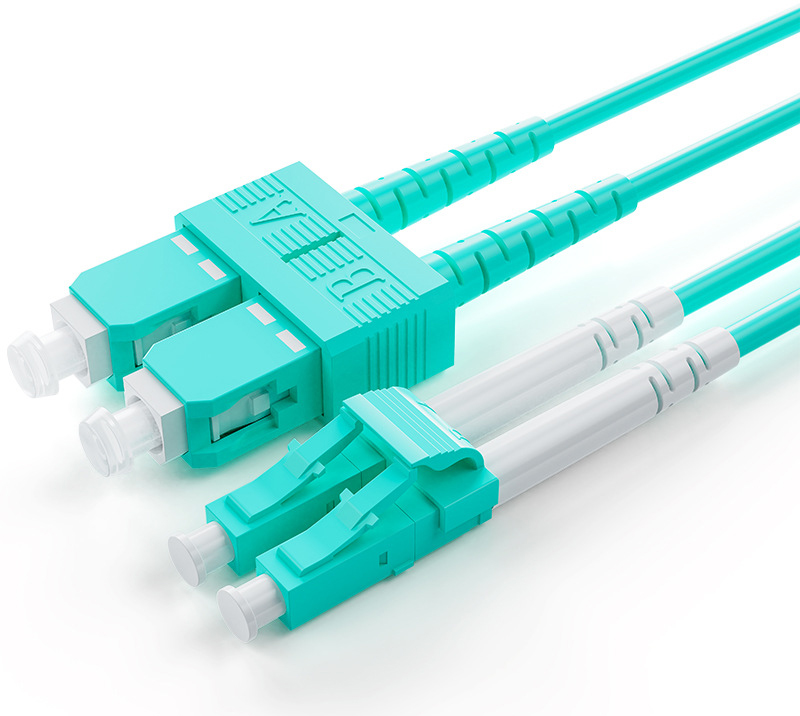

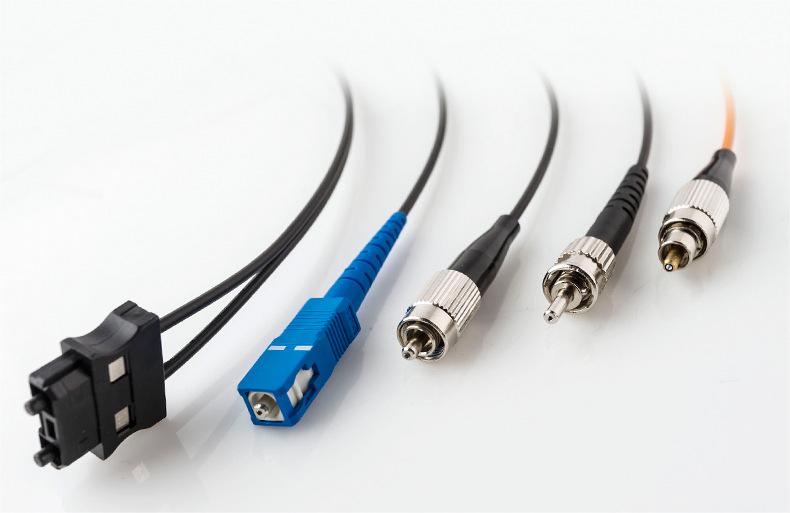

Fiber Optical Patch Cord

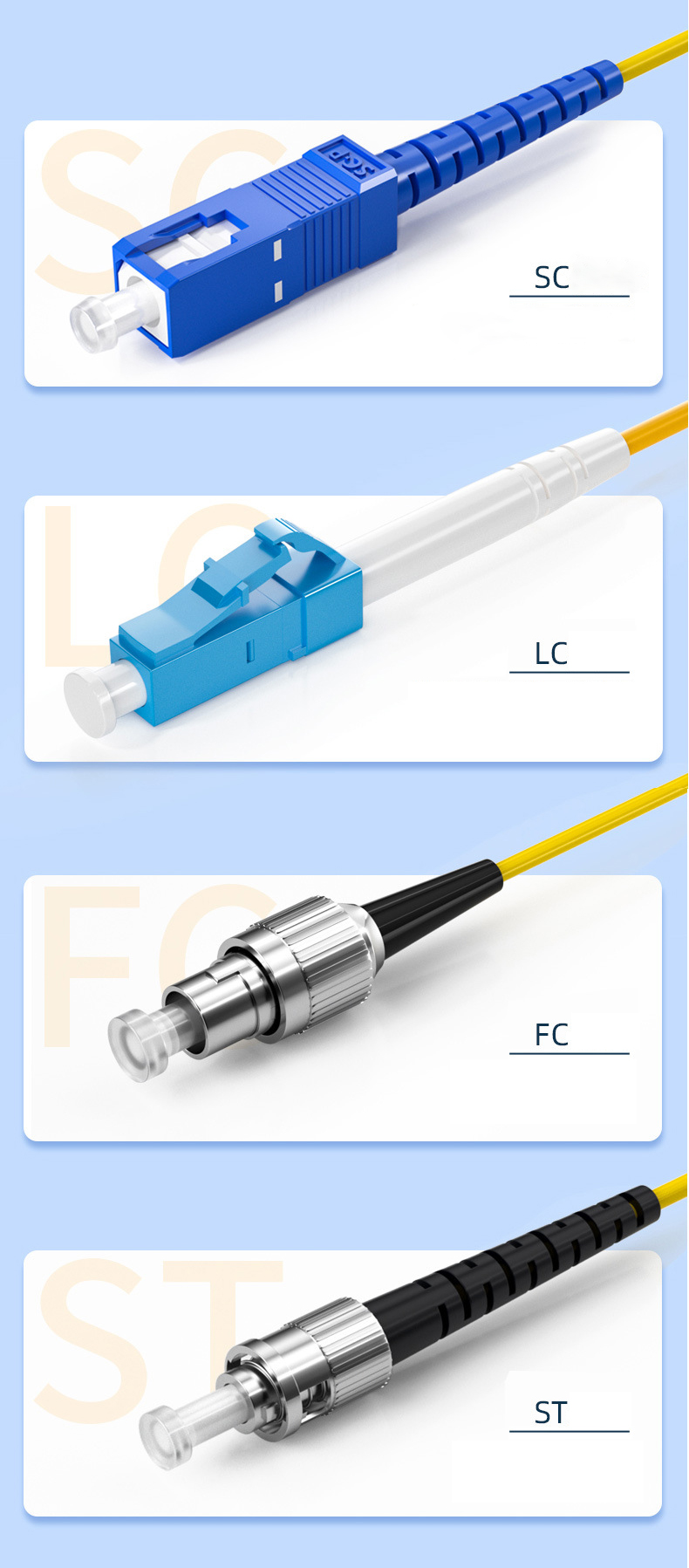

LC-LC Optical Fiber Patch Cord

The LC-LC Fiber Optic Patch Cord is a compact and versatile patch cable, extensively uti

FC-FC Optical Fiber Patch Cable

The FC FC Fiber Optic Patch Cord serves as an integral component in networking. It's des

SC-SC Optical Fiber Patch Cord

The SC SC single mode fiber optic patch cord, featuring a 3.0mm diameter, is optimally d

ST-ST Optical Fiber Patch Cable

The ST ST fiber patch cord, a vital component in fiber optic networks, is designed to co

OM1 OM2 OM3 OM4 Optical Fiber Patch Cable

OM1 OM2 OM3 OM4 Optical Fiber Patch Cable, Multimode fiber cable, known for its larger c

2 Core LC-LC Optical Fiber Patch Cable

A 2-core fiber optic cable encompasses two distinct optical fibers within its structure.

Custom Optical Fiber Patch Cable

Custom Optical Fiber Patch Cable Manufacturer,A fiber optic cable consists of five princ

What Are Pre Terminated Fiber Optic Cable Assemblies?

In the realm of fiber optic cable assemblies, pre-terminated variants are the crème de la crème. Imagine getting a suit tailored to your measurements, ready to be worn straight out of the box—that's what we're talking about here. These assemblies come with connectors already installed on either end of the fiber optic cable, saving you time, effort, and potentially human error during the installation process.

Advantages of Pre Terminated Fiber Optic Cable Assemblies

- Speedy Installation: As these are plug-and-play, you can execute deployments faster than a Wall Street trader hitting the 'buy' button.

- Quality Control: Manufactured in a controlled environment, these assemblies undergo rigorous testing by fiber optic cable assembly manufacturers, ensuring optimal performance.

- Low Loss: No worries about signal degradation here. These assemblies promise minimal loss of data transmission.

- Customization: Need something specific? Many manufacturers, including distinguished ones like YCABLE ELECTRONICS, offer custom fiber optic cable assemblies tailored to specific business needs.

Typical Applications of Fiber Optic Cable Assemblies

- Data Centers: Where speed and data integrity are the talk of the town.

- Telecommunication Networks: Boosting signals faster than gossip spreads in a small community.

- Industrial Automation: When machines converse, they prefer the eloquence of fiber optic cable harnesses.

Indoor (Plenum) Fiber Optic Cable Assemblies

- What It Is: Specifically designed for indoor environments and meeting rigorous fire safety tests.

- Best For: Offices, data centers, and other controlled environments.

Indoor/Outdoor Fiber Optic Cable Assemblies

- What It Is: A jack-of-all-trades, suitable for both indoor and outdoor use.

- Best For: Transitional spaces like entryways and exit routes in buildings.

Tactical Fiber Optic Cable Assemblies

- What It Is: Rugged, resistant, and built for the front lines.

- Best For: Military operations, field communications, and temporary setups.

Outdoor Fiber Optic Cable Assemblies

- What It Is: Designed to face the elements, come rain or shine.

- Best For: Outside plant installations, underground cabling.

Armor Options Fiber Optic Cable Assemblies

- Non-Armored: Lightweight and flexible.

- Armored: Extra protection against physical damage, ensuring data integrity.

Strand Counts and Fiber Cores Fiber Optic Cable Assemblies

- Strand Counts: You can go as petite as 2 strands or as grand as a 288-strand count.

- Fiber Core Types: Multimode OM1, OM2, OM3, OM4, OM5 or Singlemode, each tailored for specific data rate, distance, and budget requirements.

Why The Options Matter

- Customization: With such a range, you can fine-tune your choice to exactly what your operation requires.

- Scalability: Options like higher strand counts offer a future-proof pathway for network expansion.

- Cost-Effectiveness: By selecting only what you need, you get optimal ROI without overspending on unnecessary features.

If you're in the market for fiber optic cable patch cords, or fiber optic cable harness, and you want to minimize any room for error while maximizing efficiency, pre-terminated fiber optic cable assemblies are your go-to.

How to terminate fiber optic cable?

terminating fiber optic cables—the finale of a symphonic data pipeline. A well-executed termination is like the perfect last chord in a concert: crystal clear, flawless, and leaving no room for error. Shall we dive in?

Tools You'll Need

- Fiber Cleaver: For that perfect, mirror-finish cut.

- Fiber Strippers: To delicately undress the fiber down to its core.

- Connector: LC, SC, or whichever your application demands.

- Polish Film: For that final touch of elegance.

- Isopropyl Alcohol and Lint-Free Wipes: For impeccable hygiene, of course.

- Epoxy or Anaerobic Adhesive: To bind the connector and fiber like a marital vow.

Steps to Terminate Fiber Optic Cable

Preparation

- Safety First: Always don your safety goggles and gloves. Fiber shards are as dangerous as they are invisible.

Stripping

- Expose the Fiber: Use the fiber strippers to carefully remove the outer jacket, revealing the cladding and core.

- Clean: Wipe the exposed fiber with lint-free wipes soaked in isopropyl alcohol.

Cleaving

- Precision Cut: Place the fiber in the cleaver and press down for a clean, flat cut. The quality of this cut will significantly affect the signal performance.

Attaching Connector

- Mix the Epoxy: If you're using epoxy, prepare it as per manufacturer’s guidelines.

- Insert Epoxy into Connector: Use a syringe to insert the epoxy into the connector ferrule.

- Insert Fiber: Delicately place the cleaved fiber into the connector until it touches the end of the ferrule.

Curing and Polishing

- Cure the Epoxy: Follow the epoxy curing cycle per your chosen adhesive.

- Polish the Ferrule: Once cured, polish the ferrule end face using the polishing film for a smooth finish.

Testing

- Quality Check: Use an optical tester to verify that the signal passes through with low attenuation and back reflection.

How to custom fiber optic cable assemblies?

custom fiber optic cable assemblies—the haute couture of the networking world. When off-the-shelf just won't do, going custom is like having a suit tailored by Savile Row craftsmen. But how do you go from a concept to a fully functional assembly? Allow me to walk you through this art form.

Steps to Custom Fiber Optic Cable Assemblies

Step 1: Identify Your Requirements

- Application: Where will this assembly be used? Data center, outdoor environment, or perhaps something tactical?

- Cable Type: Singlemode or Multimode? Perhaps a specialty fiber like photosensitive or polarization-maintaining?

- Connector Types: SC, LC, ST? Each has its own set of pros and cons.

- Strand Count: How many fibers do you need in your cable? Could be as few as 2 or as many as 288.

- Length: How long does the assembly need to be?

Step 2: Engage with a Manufacturer

- Once you have your specs down, it's time to get in touch with reliable fiber optic cable assembly manufacturers. They'll help refine your requirements and provide engineering insights you might not have considered.

Step 3: Design Phase

- This is where the magic happens. Engineers will draft up designs, often using CAD software, to make sure all components are in harmony.

Step 4: Prototyping

- Before mass production, a prototype is often built. This is like the dress rehearsal before opening night.

Step 5: Testing

- Prototypes and even final products must undergo stringent testing, whether it's for insertion loss, return loss, or tensile strength.

Step 6: Production

- Once testing confirms that the assembly meets all specifications, mass production kicks off.

Step 7: Final Quality Check

- Even after production, a good manufacturer will perform a final quality check to make sure every assembly is up to par.

Step 8: Delivery & Installation

- Finally, your custom fiber optic cable assemblies arrive, ready to be plugged in.

Why Go Custom?

- Tailor-Made: Specific requirements need specific solutions.

- Optimal Performance: No compromises means you get the best data transmission possible.

- Scalability: Custom assemblies can grow as your network needs expand.

Creating custom fiber optic cable assemblies is a collaborative effort that requires expertise, precision, and a keen understanding of the application at hand. Companies like YCABLE ELECTRONICS can not only guide you through the intricate world of fiber optic cable harnesses, fiber optic cable patch cords, and other specialized assemblies, but they can also take your network performance to the next level.

So if you're in the market for a fiber ensemble that plays your tune perfectly, consider going custom. And if you have any questions or inquiries, you know whom to ask—the experts.

Which type of fiber optic cable is most widely used?

Singlemode Fiber Optic Cable

Why It's Popular:

- Long-Distance Data Transmission: Ideal for spanning continents or deep-sea cables.

- High Bandwidth: Enables faster data rates over extended distances.

- Less Signal Loss: Higher fidelity on those long journeys.

Best For:

- Telecommunication Networks: When you need to connect cities, countries, or even continents.

- Internet Service Providers (ISPs): Perfect for backhaul connections.

Multimode Fiber Optic Cable

Why It's Popular:

- Short-Distance Data Transmission: Excellent for links up to 2km.

- Lower Cost: Generally less expensive than Singlemode.

- Easy to Work With: Wider core size makes connections somewhat easier.

Types:

- OM1, OM2: Best for legacy installations, supporting lower speeds.

- OM3, OM4, OM5: Designed for higher data rates, ideal for modern data centers.

Best For:

- Local Area Networks (LANs): Connecting devices within a single building or campus.

- Data Centers: Where short, high-speed connections are the order of the day.

Well, it depends on your specific needs. If you're looking to cover large distances or require high data rates with minimal loss, then Singlemode is your go-to. On the other hand, if your operation is on a more modest scale in terms of distance, but you still require speed and reliability, then Multimode is more your jam.

And let's not forget that specialized applications may also demand custom fiber optic cable assemblies or even pre-terminated fiber optic cable assemblies for quick and efficient installations. Each comes with its own set of advantages, from fiber optic cable patch cords to complex fiber optic cable harnesses.

So, when selecting a fiber optic cable, it's not so much a question of which is most widely used, but rather which is most apt for your particular symphony of needs. Consult with fiber optic cable assembly manufacturers for a tailored solution. After all, even the Beatles had a producer.

Which type of fiber optic cable assembly is most widely used?

so you're keen to know the fiber optic "hit single," the one assembly that seems to get all the airtime. In the realm of fiber optic cable assemblies, the main chart-toppers tend to be Patch Cords and Pre-terminated Assemblies. Each has its own set of virtues that make it a crowd-pleaser. Allow me to introduce the headliners.

Fiber Optic Patch Cords

Why It's Popular:

- Versatility: From connecting switches to routers or linking up network devices, they are the "utility infielders" of the fiber optic world.

- Easy to Replace: Think of them as plug-and-play; no sophisticated dance moves required.

- Standardized Connectors: Usually outfitted with popular connector types like LC, SC, or ST for ease of use.

Best For:

- Data Centers: A must-have for short-distance, high-speed links.

- LANs: Local Area Networks love them for their straightforward effectiveness.

Pre-Terminated Fiber Optic Cable Assemblies

Why It's Popular:

- Time-Saving: Arrive ready for the ball—no need to spend time terminating fibers on-site.

- Quality Assurance: Manufactured and tested in controlled environments for top-notch performance.

- Customizable: Can be ordered in various configurations, from strand count to the type of fiber used.

Best For:

- New Installations: When you're setting up a new facility or network.

- Upgrades: An excellent choice for when you're jazzing up an existing setup.

Others Worth Mentioning:

- MPO/MTP Fiber Optic Cable Assemblies: Ideal for high-density environments; think orchestras with a lot of instruments.

- Armored Fiber Optic Cable Assemblies: The roadies of the fiber optic world—tough, reliable, and able to handle the rough stuff.

The "most widely used" is a bit like asking for the greatest rock 'n' roll song—it can vary depending on who you ask and what you need. Patch cords are the evergreen classics, always handy and reliable for a wide range of applications. Pre-terminated assemblies, on the other hand, are like the modern hits that make life easier and more efficient.

So whether you're looking for fiber optic cable patch cords, pre-terminated fiber optic cable assemblies, or custom fiber optic cable assemblies, your selection should echo your specific needs. And when in doubt, consult fiber optic cable assembly manufacturers for an ensemble that hits all the right notes.