Custom Battery Cable Assembly

What is a battery cable assembly?

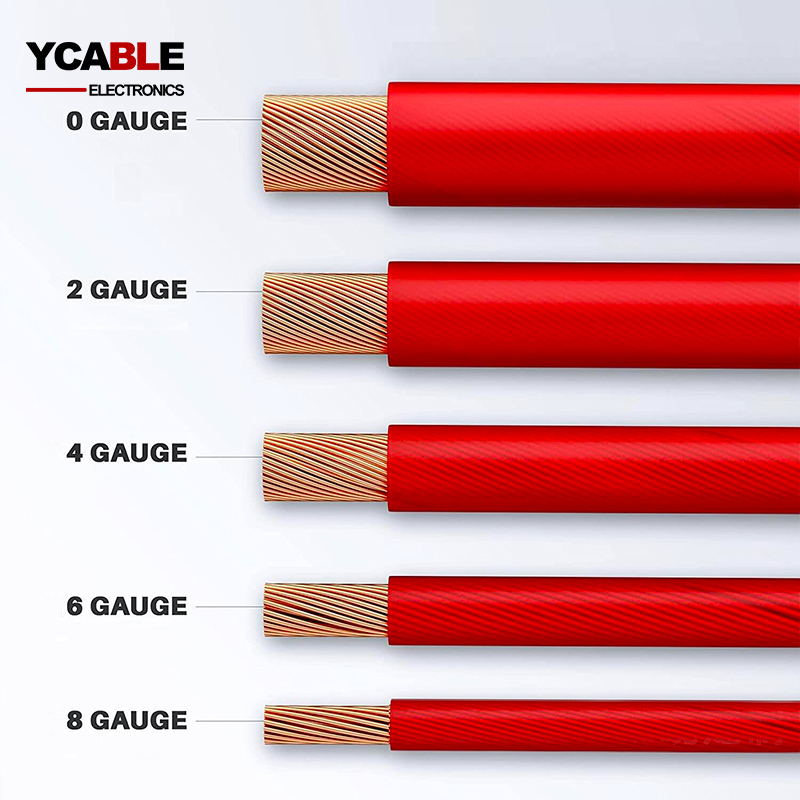

A battery cable assembly is a customized length battery cable with both ends terminated, which is used to connect one or more batteries in an electrical system. They can be terminated with a variety of electrical connector types according to our different requirements, and boots to handle just about any job. ycable electronics is a manufacturer specializing in the production of battery cable assmebly. Customization is also very simple. First determine the outer diameter of the battery cable, select the appropriate battery Cable Gauge, select according to your current and voltage requirements, and select the appropriate battery cable insulation material. You can choose silicone, flexible PVC, transparent PVC, rubber, etc. Choose the appropriate battery cable conductor material, you can choose pure copper, tinned copper, or copper-clad aluminum. Determine the length and size of the battery cable assembly, confirm the terminal types to be equipped at both ends, and finally assemble it.

Can you use aluminum wire for battery cables?

yes, we can use aluminum wire, also the copper clad aluminium wire to produce battery cable, but it's necessary to consider if you have any specific requirements of your battery cable application before choosing. So we need to know more about aluminum battery cable and copper clad aluminum battery cable, Aluminum or CCA battery cable has lower electrical conductivity compared to copper. This means for the same current carrying capacity, an aluminum or a CCA wire battery cable needs to be of a larger gauge than a copper wire, But Aluminum battery cable is lighter than copper, which can be beneficial in applications where reducing weight is a priority. It is also generally less expensive than copper battery cable, making it a cost-effective option for large-scale or budget-sensitive projects. Aluminum battery cables are often used in larger applications like power distribution systems, where the weight and cost savings are significant. In smaller applications, like automotive or consumer electronics, CCA battery cable is gradually becoming accepted, recognized, and popular.

Where are battery cable assemblies implemented?

Automotive Industry

Vehicles and Electric Vehicles, They are crucial in cars, motorcycles, trucks, and buses for connecting the battery to the starter motor, alternator, and the electrical system.

Industrial and Manufacturing

Used in construction, agricultural, and manufacturing equipment to power engines and electrical systems. Also used in generators and backup power systems, battery cables provide a connection to batteries for emergency power supply.

Marine and Aviation

Employed in marine vehicles for starting engines and powering onboard electrical systems.

Consumer Electronics

Smaller-scale battery cable assemblies are found in devices like laptops, smartphones, and portable power tools, providing power management and connectivity.

Energy Storage and Solar Systems

Solar battery cable assembly connects batteries in solar energy setups, ensuring power flow between solar panels, inverters, and storage systems.

Medical and Healthcare Equipment

In devices like defibrillators and portable medical monitors, ensuring reliable power delivery.

Hospital Power Systems: For backup power in critical healthcare settings.

Custom Applications

In custom-designed industrial or scientific equipment, tailored to specific operational requirements.