What is CCA wire?

What is CCA Wire?

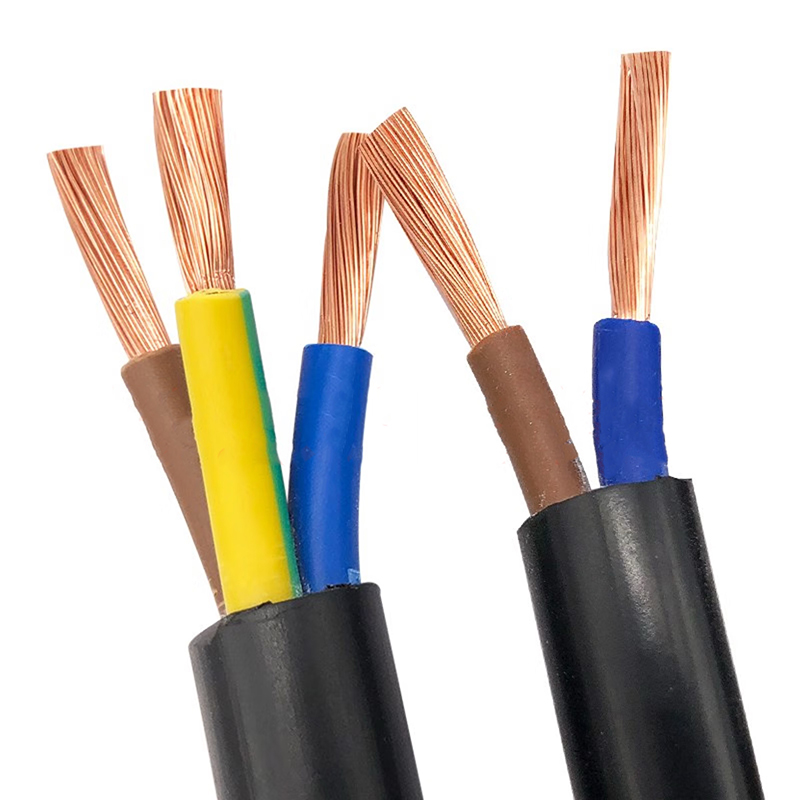

CCA wire stands for Copper Clad Aluminum wire. Essentially, a CCA wire is an electrical conductor made up of an inner aluminum core and an outer layer of copper.

Why Use CCA Wire?

There are a few key advantages to using CCA wire over traditional copper wires:

- Cost Efficiency: Aluminum is generally cheaper than copper, making CCA wire a cost-effective alternative to pure copper wire.

- Lightweight: Aluminum has about one-third the weight of copper, resulting in lighter wires that can be beneficial in specific applications where weight is a concern.

- Flexibility: The combination of aluminum and copper in CCA wires offers a good balance of flexibility and strength.

Applications of CCA Wire While CCA wire has found its usage in various applications, a few noteworthy ones include:

- CCA Speaker Wire: An excellent choice for transmitting audio frequencies in speaker systems. The copper provides good conductivity while the aluminum ensures the wire remains lightweight.

- CCA Power Cable: Designed for transmitting electrical power, these cables benefit from the combined attributes of copper and aluminum to offer both efficient power transmission and reduced weight.

Is copper clad aluminum wire good for automotive?

CCA Wire in the Automotive World

Pros:

- Weight Reduction: Vehicles constantly aim for weight reduction to achieve better fuel efficiency. Since aluminum is lighter than copper, CCA wires can contribute to this goal.

- Cost-Effective: Aluminum is generally less expensive than copper. As such, using CCA wires can potentially reduce production costs for vehicle manufacturers.

- Resistance to Corrosion: The copper exterior of CCA wire offers better resistance to corrosion, especially when compared to bare aluminum. This is an essential trait given the varying conditions a vehicle might be exposed to.

Cons:

- Conductivity: Copper has almost twice the conductivity of aluminum. Even though the exterior of CCA wire is made of copper, it can't entirely match the electrical performance of pure copper wire.

- Durability Concerns: Aluminum is more brittle than copper, which can lead to potential issues of wire breakage under constant flexing — a situation that might arise in a dynamic vehicle environment.

- Resistance and Heat: Due to its lower conductivity, aluminum has a higher resistance, which can lead to more heat generation when current flows through. In tightly packed automotive environments, managing additional heat can be challenging.

- Connectivity Issues: Aluminum can oxidize, and these oxides can increase resistance at connection points. Although the copper exterior helps reduce this, it's still a point to consider, especially for long-term applications.

While copper clad aluminum speaker cables and CCA power cables have found their niche in various applications, the automotive sector demands careful consideration. Some manufacturers may opt for CCA wires in specific applications where the advantages outweigh the drawbacks. Commonly used car CCA wire and cables include booster cables, audio cables, amplifier wiring kits, etc

However, the general consensus in the automotive industry is a preference for pure copper wires, especially in critical systems, due to their superior conductivity and durability.

For businesses in the automotive B2B space, it's essential to align with partners like YCABLE ELECTRONICS, with their vast experience and ISO 9001 certification, to guide on the best wire choices tailored for specific applications.

Is cca wire bad ?

The Good of CCA wire:

- Cost-Effective: Aluminum is typically less pricey than copper. Thus, CCA wire offers a more economical alternative compared to pure copper wire.

- Lighter Weight: Aluminum weighs roughly a third of copper. Hence, CCA wire can be a boon in applications where wire weight plays a role.

- Anti-Corrosive: Thanks to the copper exterior, CCA wires have better resistance to corrosion compared to bare aluminum.

The Bad of CCA wire (or let's say, the considerations):

- Lower Conductivity: Copper’s conductivity is nearly double that of aluminum. So, while CCA wires do conduct electricity, they don't perform as efficiently as pure copper wires in this aspect.

- Durability Issues: Aluminum tends to be more brittle compared to copper. This can result in potential breakage or wear, especially in applications requiring frequent flexing.

- Heat Concerns: The higher resistance of aluminum can lead to increased heat generation when electricity flows through. This can be a concern in packed environments or where heat dissipation is a challenge.

- Connection Issues: Aluminum can form oxides that increase resistance at connection points. Even with its protective copper shell, CCA wire might still experience this issue over time.

The Specific of CCA wire:

It’s imperative to note that the "goodness" or "badness" of CCA wire truly depends on the specific application. For instance:

- CCA Speaker Wire: CCA might serve well in audio applications where high-fidelity isn't the primary concern. But for premium audio systems, pure copper might be the preferred choice.

- CCA Power Cable: In some scenarios, the lightweight and cost-effective nature of CCA might make it desirable. Yet, pure copper might be more suitable for high-power or critical applications.

CCA wire isn't inherently "bad." However, its utility is subject to the specific requirements of a given application. It's about horses for courses. For those diving deep into the B2B world of cables, teaming up with a seasoned expert, like YCABLE ELECTRONICS, can offer guidance on selecting the ideal wire type tailored to the desired application.

Copper clad aluminum wire manufacturers

Raw Material Acquisition:

- Aluminum Core: The primary material, aluminum, is sourced in its pure form.

- Copper Coating: High-purity copper, required for the cladding process, is obtained.

Cladding Process:

- Here, the magic happens. Copper is cladded or coated over the aluminum rod through either an extrusion or a cladding process.

Wire Drawing:

- Post-cladding, the thicker wire is drawn through a series of dies to reduce its diameter to the desired thickness. This process ensures the wire's strength and flexibility.

Annealing:

- The drawn wire is then annealed, or heated, to improve its ductility and relieve stresses caused by the drawing process.

Insulation (if required):

- Depending on the intended application, an insulating layer may be added to the wire. For instance, cca speaker wire might get a specific insulation type suitable for audio applications, while a cca power cable may have a different insulation optimized for power transmission.

Quality Checks:

- Essential for maintaining the integrity of the product. The wire undergoes various checks, including conductivity tests, tensile strength evaluations, and thickness verifications.

At this stage, the CCA wire can be considered a semi-finished product. It's now ready to be wound onto spools, further processed, or integrated into other products based on the requirements.

Sourcing Semi-Finished stranded or twisted CCA Wires

For B2B businesses seeking semi-finished CCA wires, collaborating with trusted manufacturers is crucial. With roots dating back to 2012 and a commitment to quality reflected in their ISO 9001 certification, YCABLE ELECTRONICS stands as an esteemed figure in this domain. By offering a diverse range of CCA products, from copper clad aluminum speaker cables to various other types, YCABLE ensures businesses get the right semi-finished product tailored to their specific needs.

| CCA Wire | ||||

| Size(mm2) | Construction(Strand No./Dia.) | Resistance | Tensile Strength | Elongation rate |

| 0.60/0.50 | 19/0.20(10/0.26) | 42.2 | 100-150 | 1-25% |

| 0.75 | 19/0.23(14/0.26) | 34.18 | ||

| 1 | 19/0.26 | 26.75 | ||

| 1.5 | 19/0.32(28/0.26) | 17.65 | ||

| 2 | 19/0.36(38/0.26) | 13.95 | ||

| 2.5 | 19/0.41 | 10.32 | ||

| 3 | 19/0.47 | 8.32 | ||

| 4 | 19/0.53 | 6.48 | ||

| 5 | 19/0.59 | 5.23 | ||

| 8 | 19/0.73 | 3.42 | ||

| 10 | 19/0.82 | 2.7 | ||

| 15 | 19/1.01 | 1.75 | ||

| 20-400 | Custom by Customer's requirement | |||

CCA vs Copper Speaker Wire

Conductivity & Signal Transmission

- CCA (Copper Clad Aluminum) Speaker Wire: Aluminum is less conductive than copper. While the exterior copper cladding does enhance its conductivity, CCA wire generally has about 1.5 to 2 times the resistance of pure copper for the same cross-sectional area. This might lead to a slight reduction in the speaker's power, especially for long wire runs or high-power audio systems

- Pure Copper Speaker Wire: Copper is one of the best electrical conductors, ensuring minimal resistance and optimal signal transmission, especially over long distances.

Durability & Flexibility

- CCA Speaker Wire: Aluminum can be more brittle than copper. This means CCA wires, under continuous flexing or bending, might be more prone to breakage over time.

- Pure Copper Speaker Wire: Copper is more ductile, allowing the wire to endure bending and flexing better.

Weight & Installation

-

CCA Speaker Wire: Lighter than pure copper, potentially making it easier to handle during installations, especially in cases of long runs.

-

Pure Copper Speaker Wire: Denser and heavier, which might require more effort in handling and installation.

Cost

-

CCA Speaker Wire: Generally more cost-effective due to the use of aluminum, which is cheaper than copper.

-

Pure Copper Speaker Wire: Typically more expensive, reflecting the market price of copper.

Heat Dissipation

-

CCA Speaker Wire: Due to its higher resistance, CCA wire can generate more heat compared to pure copper when transmitting the same amount of current. This might not be a significant issue for average home audio setups but can be a consideration for high-power systems.

-

Pure Copper Speaker Wire: Exhibits better heat dissipation, keeping the system cooler during high-power transmissions.

Both CCA and pure copper speaker wires have their merits. The choice often boils down to specific requirements like budget constraints, distance of the wire run, and the audio system's power.

For premium or professional audio setups, pure copper is often preferred due to its superior conductivity and durability. However, in environments where cost or weight is a significant concern, CCA might be a viable alternative, provided the limitations are understood.

In the B2B domain, understanding the nuances between these two types can greatly benefit businesses. Especially when sourcing from experienced manufacturers like YCABLE ELECTRONICS, businesses can make informed decisions tailored to their clientele's needs.

Copper Clad Aluminum Typical Physical Properties

CCA 21%

| Specification | CCA 0.25mm | PARTNO |

| |||||

| 1. (Appearance and Measurement) | ||||||||

| Diameter (mm) | Thickness of copper (mm) | Appearance

| Copper | Adhesion between copper and aluminum | ||||

| 0.251 | ≥0.0087 | Smooth | 21% | Pass | ||||

| 2. Performance lndex | ||||||||

| Tensile Strength (MPa) | Elongation (%) | Resistivity at200C (Ω·mm2/m) | Density at200C g/cm3 | Copper by volume (%) | ||||

| 124 | 11.9 | ≤0.02678 | 3.20 | 8 | ||||

CCA 4%

| Specification | CCA-D 0.25mm | PARTNO |

| |||||

| ||||||||

| Diameter (mm) | Thickness of copper (mm) | Appearance

| Copper | Adhesion between copper and aluminum | ||||

| 0.25 | ≥0.001 | Smooth | 4% | Pass | ||||

| ||||||||

| Tensile Strength (MPa) | Elongation (%) | Resistivity at200C (Ω·mm2/m) | Density at200C g/cm3 | Copper by volume (%) | ||||

| 124 | 10.9 | ≤0.02729 | 2.80 | 2 | ||||

The YCABLE Edge For businesses looking to leverage the advantages of copper clad aluminum wire, it's crucial to partner with experienced manufacturers who uphold stringent quality standards. Established in 2012, YCABLE ELECTRONICS specializes in OEM cable & wire manufacturing, offering a wide range of custom CCA wire products, from cca speaker wire to cca power cable. Certified with ISO 9001, the company's dedication to excellence ensures top-tier products for diverse fields.

In the world of wires, the CCA variant stands out as a unique blend of efficiency and innovation. And with manufacturers like YCABLE ELECTRONICS, businesses are assured of quality products tailor-made for their requirements.