The Best Cable, Wire, Wire Harness, Cable Assembly Manufacturer In China

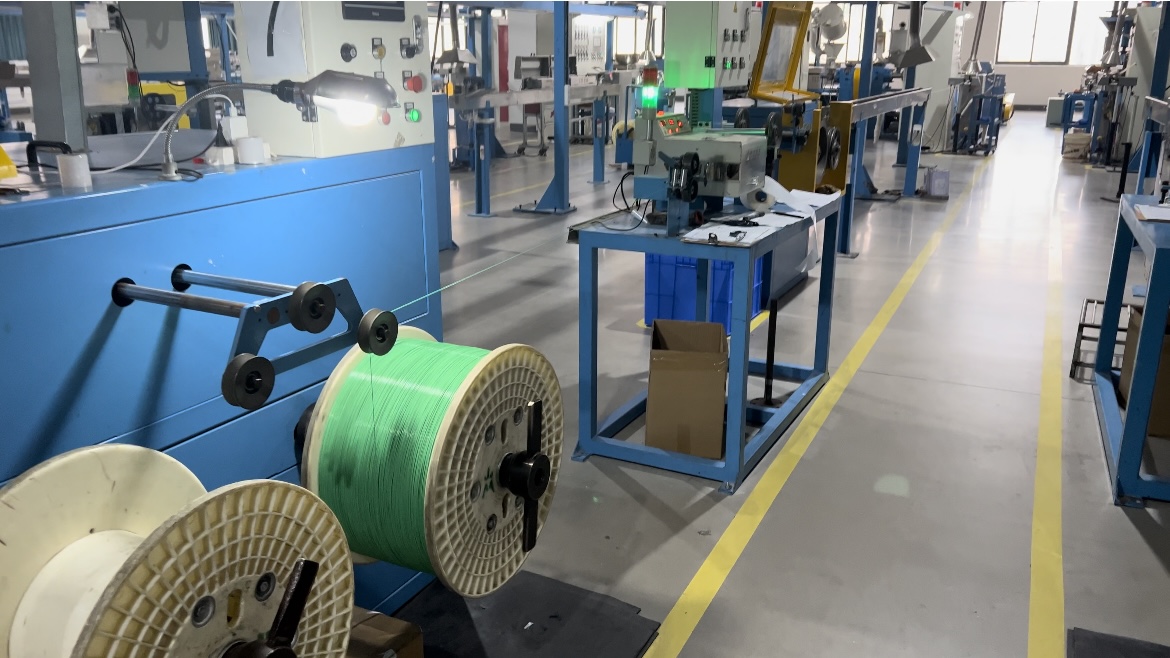

Welcome to YCABLE ELECTRONICS! We focus on providing customers with high-quality and high-performance custom cable and wire, wire harness and cable assembly solutions. As a leading manufacturer in the industry, we are committed to providing the best customer experience and meeting various industry needs.

Our main products and services include:

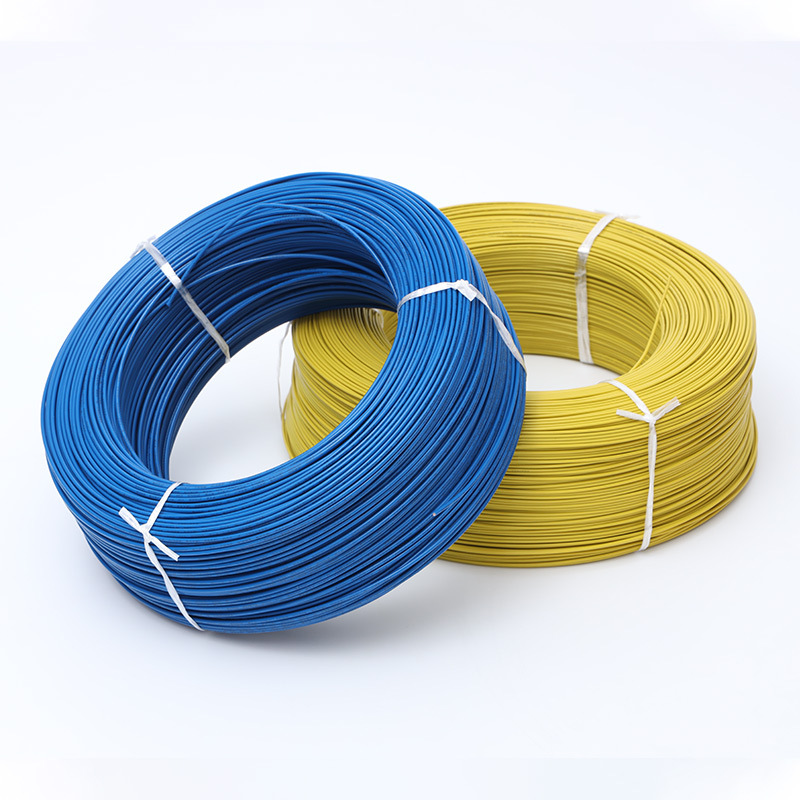

1. We can accept custom cable and wire orders: We provide various types of custom cable and wire, such as custom high temperature wire, custom power cable, custom network cable, custom coaxial cable, etc. We can custom shielded cable, custom solar cable, custom energy EV cable, and more. Strictly follow international standards for production to ensure product performance and safety.

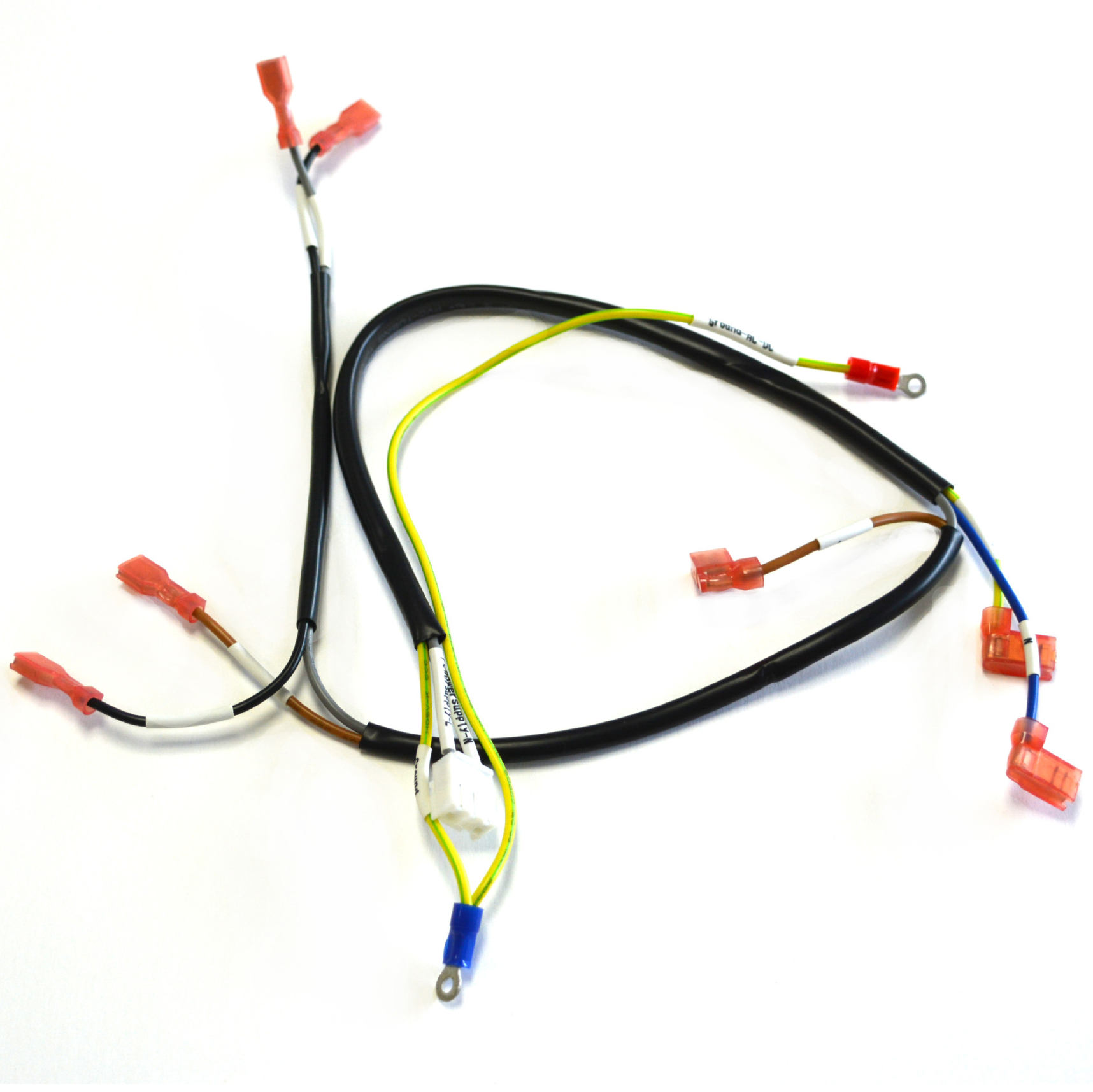

2. We can custom wire harness: Our wire harness are suitable for various industries and applications, such as automotive wire harness, waterproof wire harness, RF coaxial wire harness, fiber optic cable assembly, etc. We provide complete wire harness design, production, assembly, and testing services to ensure the reliability and durability of the wire harness.

3. We have a professional customization team: our team of professional engineers can provide personalized solutions to meet your specific needs. From design, material selection, production to quality control, we strictly control and ensure that we provide you with the highest quality custom products.

4. Strict quality control: We use advanced production and testing equipment to strictly monitor each production process. We adhere to the international quality management system and have passed ISO 9001 and IATF 16949 certifications to ensure that our product quality and service level meet industry standards. Designed and produced according to IPC standards and industry standards, with advanced production and testing equipment.

5. Quick response and delivery: We value customer needs and strive to provide fast and flexible services. From sample production to production, we ensure to provide you with satisfactory products in the shortest possible time.

Choose our custom cable, wire, wre harness, cable assembly products to make your products and projects even better!

How to make a custom cable?

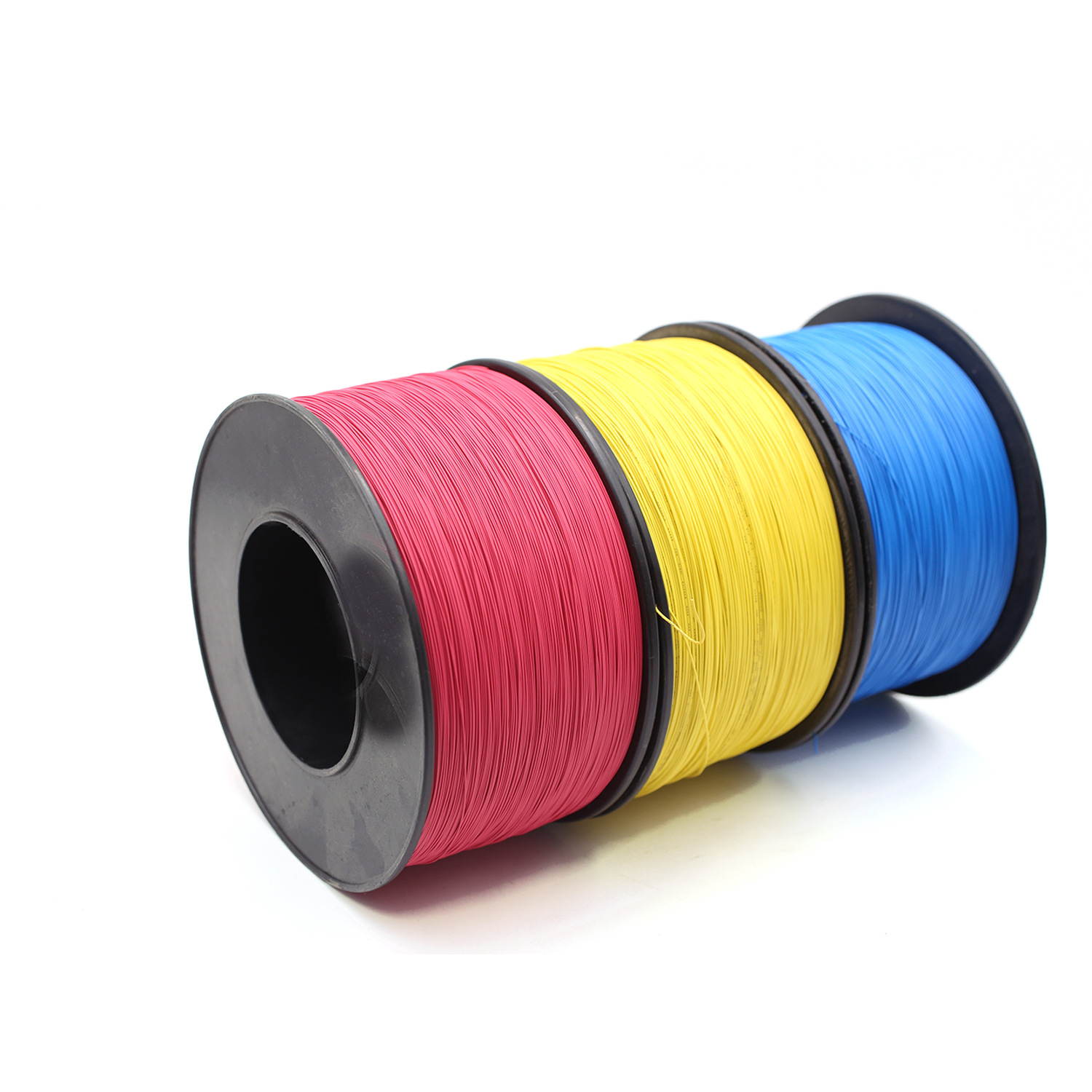

1. Choose appropriate materials: The main materials for wire include conductors, insulation materials, shielding materials and jacket materials. We will select suitable materials based on your needs and application scenarios.

2. Design wire specifications and structure: consider parameters such as wire diameter, length, number of conductors, shielding requirements, etc. Ensure that the wire meet relevant industry standards and customer usage environment requirements.

3. Preparation of conductors: Design the conductor structure based on the current or resistance requirements, and use a stranding machine for stranding.

4. Making insulation: Wrap the stranded conductor with suitable insulation material and control the wire diameter

5. Shielding production (if necessary): Lay the shielding material on the insulation layer.

6. Sheath production: If woven shielding or multi-core wire are required, we need to produce a layer of sheath to protect the wire.

7. Quality inspection: During the production process, regularly check the quality of the wire to ensure that they meet design requirements and industry standards.

8. Complete and Test: After completing all production steps, conduct electrical performance tests on the wire to ensure their good performance.

What custom cable and wire can we produce?

custom network cable, custom coaxial cable, custom high-temperature cable, custom power cable, custom shielding cable, custom parallel cable, custom audio cable, custom car cable, etc

How to make a custom wire harness or cable assembly?

1. Determine the demand: first, communicate with the customer to understand the specific requirements of the use, length, terminal type, connector type, circuit demand, etc. of the harness.

2. Design wire harness: According to the requirements, design the layout of the wire harness, circuit diagram, and specifications of each wire. Ensure that the design meets relevant industry standards and regulatory requirements, and evaluate the feasibility before confirming the design with the client.

3. Preparation of materials: According to the design requirements, prepare the necessary wire, connectors, terminals, sheath materials, etc.

4. Strip the insulation layer: use Wire stripper or peeling machine to remove the insulation layer at both ends of the wire, and arrange the wire.

5. Crimping terminal: Connect the wire to the terminal. Firstly, insert the wire into the terminal, and then use crimping pliers or other special tools to press the terminal tightly onto the wire. Ensure that the crimping is firm and free from looseness.

6. Assembly of wire harness: Arrange the wire that have been pressed onto the terminals according to the design layout, and fix them with tape or wire harness ties. If there are multiple layers of wire harness, attention should also be paid to interlayer isolation and fixation.

7. Connector installation: Connect the wire harness to the connector. Usually, it is necessary to insert the connector into one end of the wire harness and then use screws or other fixing devices to secure the connector to the terminal.

8. Sheath and sealing: Add sheath materials such as corrugated pipes, PVC pipes, etc. to the wire harness as needed. Use tape, wire harness ties, or heat shrink tubing to secure the sheath material to the wire harness. If there are waterproof and dustproof requirements, sealing treatment is also required.

9. Quality inspection: During the production process, regularly check the quality of the wire harness to ensure that it meets design requirements and industry standards.

10. Complete and Test: After completing all production steps, conduct electrical performance tests on the wire harness to ensure its good performance. If there are any problems, make timely adjustments and repairs.

What wire harness can we custom?

Automotive wire harness, waterproof cable harness, battery cable harness, PCBA wire harness, medical cable harness, photovoltaic wire harness, audio wire harness, etc.