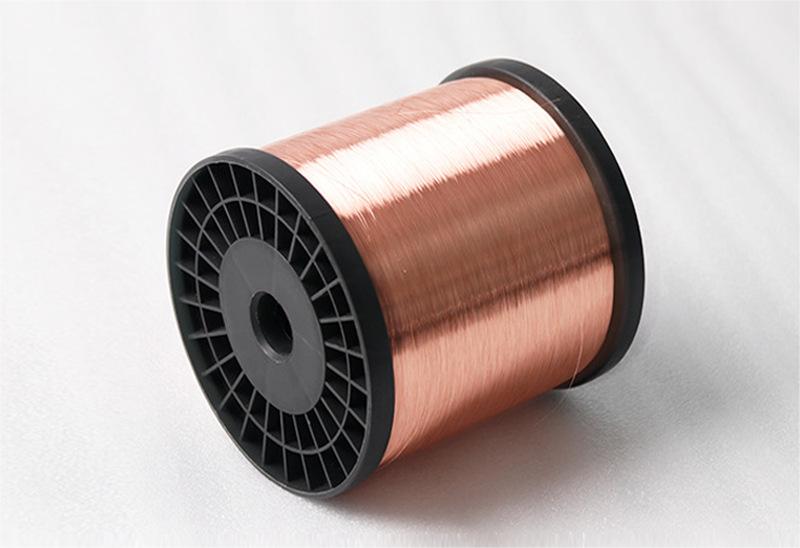

CCA Wire 5% 10% 25% 75% Stranded Wire Copper Clad Aluminum Wire Manufacturer

CCA Datasheet

CCA Wire 25% Twist Copper Clad Aluminum Wire

YCABLE ELECTRONICS can offer you high copper percent CCA wire, 21%, 25%, and up to 80%,

CCA Wire 5% Stranded Copper Clad Aluminum Wire

YCABLE ELECTRONICS has produced CCA wire for many years, We export to many countries, in

What is CCA wire? What is copper clad aluminum wire?

Copper clad aluminum wire, abbreviated as CCA wire, refers to the product obtained by coating aluminum as the core wire with copper (or copper alloy) at high temperature. The thickness of the outer copper layer of copper clad aluminum wire is generally between 10% and 15%. The core wire is generally made of copper wire or copper strip, and the outer copper layer can be made of thin strips or thin layers of materials such as red copper, silver copper, or gold copper. The copper content ranges from 5% to 25%, and we also support customized copper content.

- 10A copper clad aluminum wire is a soft state copper clad aluminum wire with a copper layer volume ratio of 10%.

- 10H copper clad aluminum wire is a hard state copper clad aluminum wire with a copper layer volume ratio of 10%.

- 15A copper clad aluminum wire is a soft state copper clad aluminum wire with a copper layer volume ratio of 15%.

- 15H copper clad aluminum wire is a hard copper clad aluminum wire with a copper layer volume ratio of 15%.

In addition, according to the volume ratio of the copper layer and the different soft and hard states, it also has types of copper clad aluminum wires such as 20A and 20H

Due to its low cost, copper clad aluminum wire has been widely used in some fields with high cost requirements. Among them, the most important application is in the power industry, such as for power transmission, power lines, transformer coils, welding machines, and other aspects. In addition, copper clad aluminum wires can also be used for internal wiring connections of various electronic and electrical devices.

Overall, copper clad aluminum wire is a product with great potential in the electrical industry. It can reduce the cost of wiring and provide a better solution for the electrical industry. However, it should also be noted that selecting appropriate conductive materials remains a key focus of industry attention.

What is CCA wire used for?

Copper clad aluminum wire consists of an aluminum core and a continuous copper layer wrapped around it, with the copper layer fully bonded to the core wire. The quality of copper clad aluminum wire should meet the requirements of this standard and can be used as a conductor for coaxial cables and wires and cables in electrical equipment.

The main function of copper clad aluminum wire is to transmit signals, and the current flowing through it is very small, making it widely used on coaxial lines. Of course, copper clad aluminum wire can be used for the production of power cords, socket cords, coaxial RF cables, network cables, construction cables, battery cables, welding cables, speaker cables, etc.

Copper clad aluminum wire also has other wide applications: applied in bus ducts, switchgear, control cabinets, transformers, safety switches, vacuum switches, relay systems, motor control centers, track power supply systems, electrode correction coils, reactors and other windings, railway traction equipment, high, medium and low voltage distribution cabinets, generator sets and substations, various copper aluminum transition joints, high and low voltage distribution cabinets, conductive bars, high and low voltage busbars, and busbars, In power equipment such as sliding wires.

What is the difference between CCA and OFC wire?

Copper clad aluminum wire can not only effectively replace pure copper in a considerable field, but also greatly reduce manufacturing costs. This product replacing pure copper will have a strong driving effect on the development of the national economy, the improvement of technical level in related industries and fields, and the reduction of manufacturing costs.

Copper clad aluminum enameled wire has obvious advantages compared to pure copper enameled wire:

- Lightweight: The density of copper clad aluminum enameled wire is one-third of that of pure copper wire with the same wire diameter, which is very effective in reducing the weight of cables and coils. In the field of audio coils, it significantly improves product performance.

- Good DC resistivity: The DC resistivity of copper clad aluminum enameled wire is about 1.5 times that of pure copper wire; When the resistance value is the same, its wire diameter is about 1.2 times that of pure copper, while the weight of copper clad aluminum wire is only half that of pure copper wire. According to the "skin effect" calculation, at high frequencies above 5MHz, the resistivity is the same as that of pure copper wire. Therefore, when used in digital cables and high-frequency signal cables, its electrical performance is the same as that of pure copper wire.

- Good solderability: Copper clad aluminum enameled wire has the same solderability as pure copper wire due to its concentric coating on the surface, without the need for special treatment like aluminum wire.

- Low cost: Compared with pure copper enameled wire, copper clad aluminum enameled wire can reduce production costs by 30-50% in certain fields of use

- Compared to pure copper wire, copper clad aluminum wire is of no value to thieves because it is almost impossible to separate the pure copper coating from the aluminum core wire. Therefore, additional anti-theft effects can be achieved.

- 6. Copper clad aluminum wire is lightweight, easy to transport and install, and reduces labor costs.

- 7. Copper clad aluminum wire is more plastic than copper wire and does not generate insulating oxides like aluminum, making it easier to process and has better conductivity

Is copper clad aluminum wire good? Is CCA cable bad?

CCA wire is also good, not bad. Copper clad aluminum wire refers to a new conductor material formed by coating a thin copper layer on the aluminum core wire and metallurgical bonding of atomic bonds at the interface between copper and aluminum.

Copper clad aluminum wire not only leverages the excellent conductivity of copper and the lightweight characteristics of aluminum, but also overcomes the drawbacks of aluminum oxidation, high contact resistance, and difficulty in welding joints. It greatly saves copper resources in China and reduces the cost of conductors. Therefore, its application scope in the online cable industry is gradually expanding.

The proportion of copper layer area on the cross-section of copper clad aluminum wire is called the "copper layer volume ratio".

Copper clad aluminum wire can be divided into:

- The volume of copper layer accounting for 8% to 12% is represented by 10%;

- The volume of copper layer accounting for 13% to 17% is represented by 15%.

Copper clad aluminum wire can be divided into:

- Retained the hard conductor in the work-hardened state during drawing;

- A soft conductor that eliminates work hardening through annealing.

Is copper clad aluminum wire safe?

Copper clad aluminum wire is safe and widely used in the cable television industry. In the United States, copper clad aluminum wire has become the standard material for coaxial cables. Due to the fact that high-frequency signal transmission operates on the outer layer of the wire, copper clad aluminum wire can replace copper wire of the same specification. In low-frequency applications, the installed capacity of copper clad aluminum wire is 65% of that of copper wire of the same specification. Due to its light weight, it is also softer than copper when large wire sizes are needed. Therefore, copper clad aluminum wire is a good wire for battery cables, welding cables, building cables, and electromagnetic wires. Due to the excellent performance of practical copper clad aluminum wire, it is necessary to use practical copper clad aluminum wire in many places today.

Copper clad aluminum enameled wire can be used for signal transmission, but now it is used for power transmission and is prone to problems, and its product lifespan will be greatly reduced. When using copper clad aluminum enameled wire, attention should be paid to the oxidation protection of the lower section of the enameled wire to ensure the effective combination of copper and aluminum, which can be used for a long time.

Copper clad aluminum wire and copper clad aluminum enameled wire are actually not applicable in many fields, but in fact, many enterprises use them for transformers. The concern with the use of copper clad aluminum wire is that its electrical resistivity is higher than that of constant cross-section copper, and there is a problem of temperature rise; The oxidizability of aluminum wire material will further increase the wire resistance and prevent oxidation measures.