Custom Flat Cable Manufacturer Power Cables

What is Flat Power Cable?

Space-Efficient Configuration

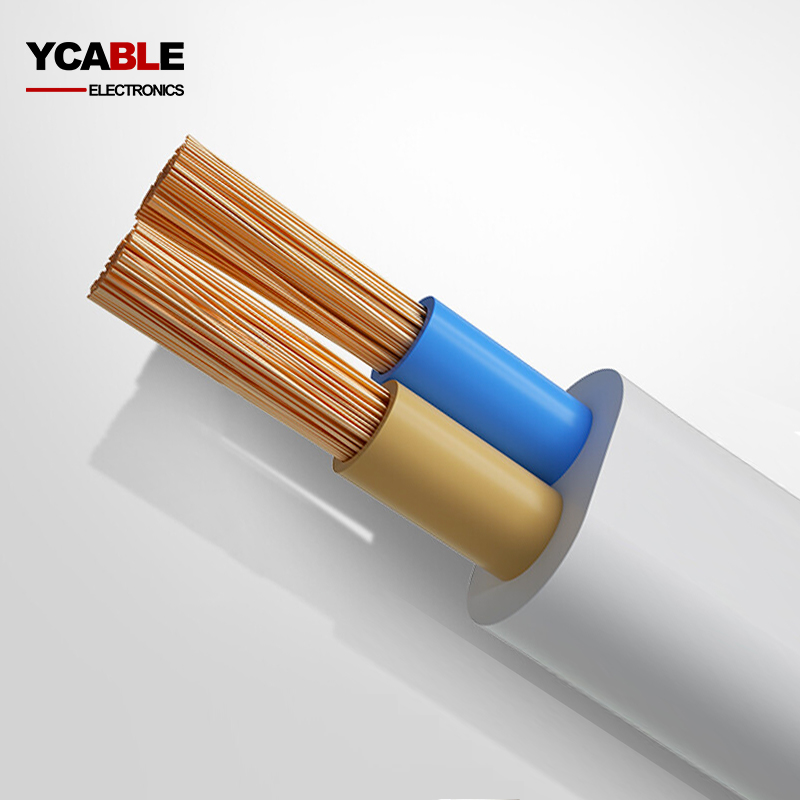

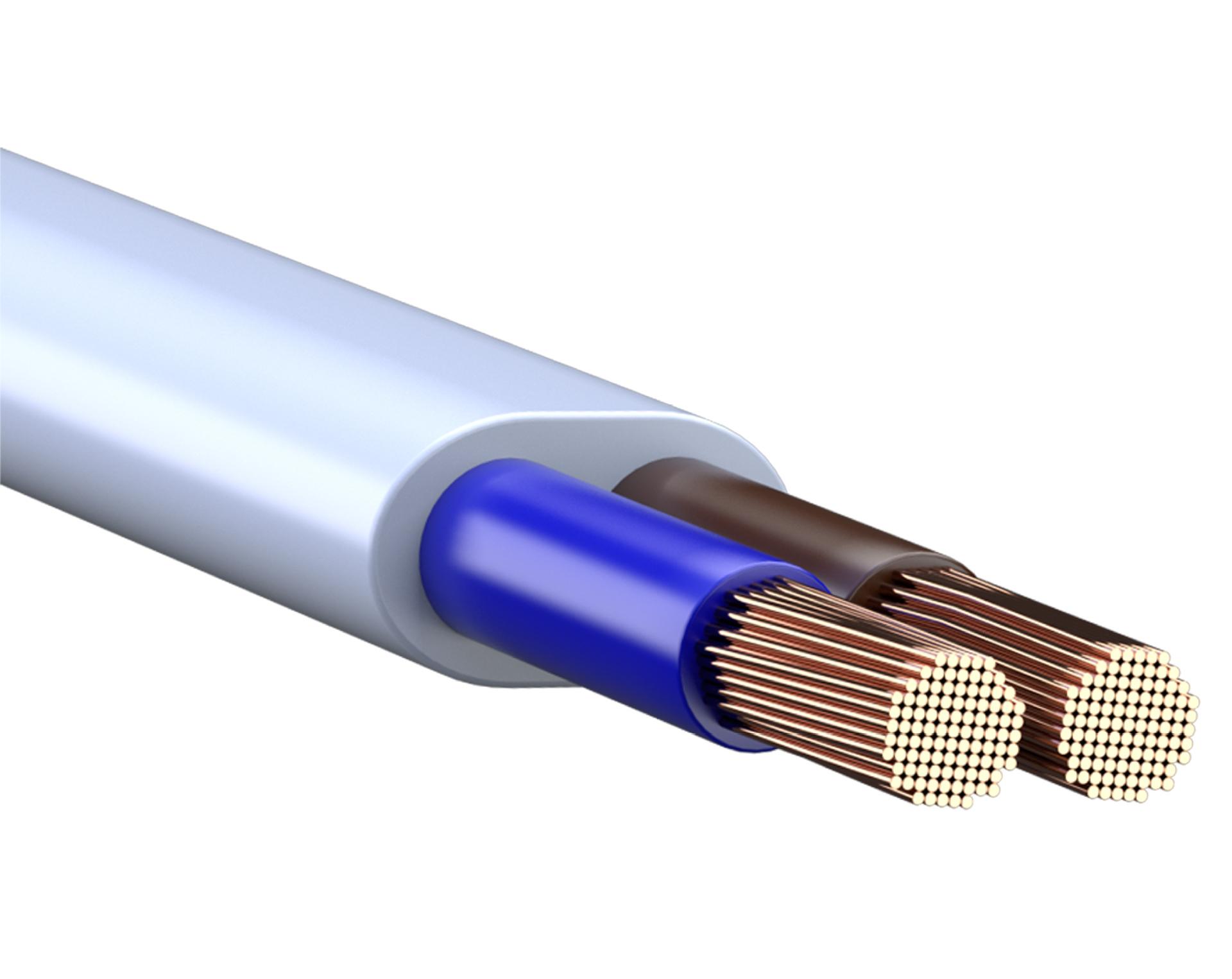

Flat cables, a specialty of flat cable manufacturers, offer an innovative approach to integrating various electrical conductors and tubing. These cables adeptly combine power, signal, video, data, and even pneumatic tubing into a singular, flat configuration. The absence of multiple layers of fillers, shielding, and jacketing, commonly found in round cables, results in a marked decrease in both spatial footprint and weight, alongside a significant extension in lifespan.

Superior Flexibility and Versatility

The streamlined, uncluttered design of flat cables provides greater flexibility compared to traditional round cables, particularly beneficial in high-flex environments like robotic systems, festoon setups, and automated processing machinery. Their suitability extends to sectors demanding high precision and reliability, such as military, aerospace, medical, and clean room applications. The uniform flexing behavior of flat cables, occurring within a single plane, substantially reduces the twisting and stress typically experienced by round cables. Their capacity to conform to small bend radii allows them to adapt to confined spaces, and they are engineered to withstand up to tens of millions of flex cycles.

Enhanced Electrical Performance

In flat cables, conductors are uniformly spaced and follow an identical path, unlike the variable and changing routes found within round cables. This consistent spacing and linear travel in flat cables lead to a superior electrical performance characterized by quicker signal transmission, minimized signal skew, and an increased capacity for carrying current.

Benefits of Flat Cables

Enhanced Flexibility for Dynamic Applications

Flat cables are particularly advantageous in motion-centric applications like robotics, axis-control manufacturing equipment, and automated medical diagnostics. Their conductors are aligned in a parallel formation within a flat plane, significantly reducing the bend radius compared to round cables. While conductors in round cables may suffer from kinking or "corkscrewing" under repeated bending, flat cables boast a flex-cycle life of up to 15 million cycles, making them more suitable for applications requiring frequent bending and tight bend radii.

Space Optimization

In the realm of increasingly dense electronic packaging, flat cables offer a substantial space-saving benefit. Their flat structure enables them to occupy about half the space required by equivalent round cables.

Weight Reduction

Flat cables are designed to be mechanically robust without the need for large conductors. This allows for a reduction in the copper cross-section to only what is necessary for carrying the required current load or meeting voltage-drop criteria, leading to a significant decrease in weight. This is achieved without relying on additional insulating materials, fillers, or tapes, typically found in round cables.

Uniform Electrical Characteristics

Flat cables maintain fixed conductor spacing and consistent geometry, ensuring steady electrical characteristics. This uniformity in impedance, capacitance, inductance, time delay, crosstalk, and attenuation contributes to reliable performance.

Increased Current Carrying Capacity

The greater surface-to-volume ratio of flat cables enhances their heat dissipation efficiency. As a result, flat cables can handle higher current levels for a given temperature rise and conductor cross-section compared to round cables.

Minimized Skewing

The identical physical and electrical lengths of conductors in flat cables, along with their continuous and consistent dielectric, effectively minimize time delays between signals, thereby reducing skewing effects.

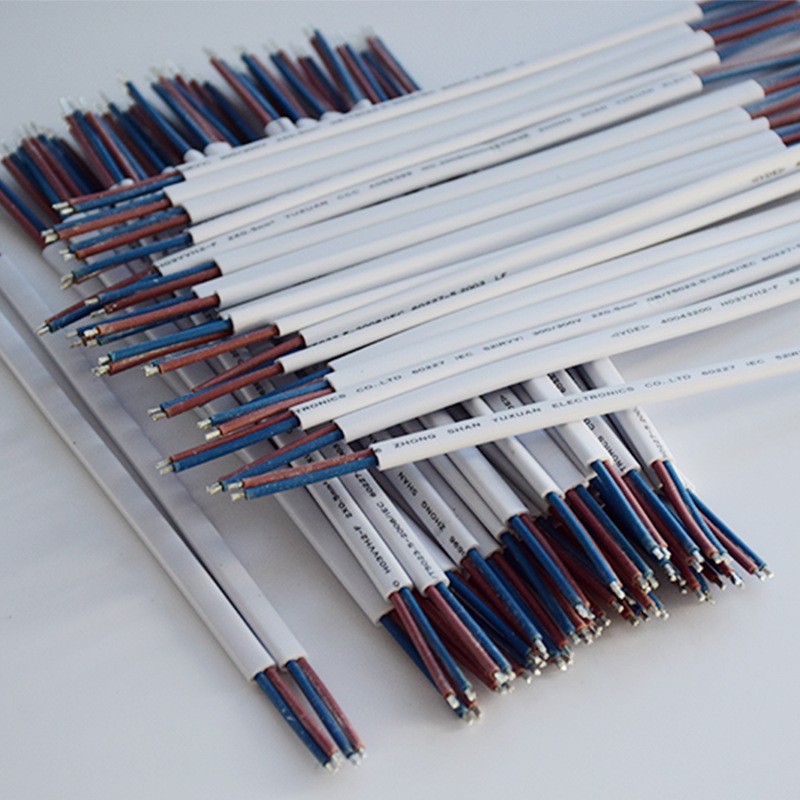

Streamlined Organization and Handling

Flat cables allow for the consolidation of different conductor types—such as twisted pairs, single conductors, coaxial, both shielded and non-shielded types—into a single cable. This integration streamlines design, assembly, and maintenance processes by simplifying the management of multiple conductors.

Versatile Design Solution

While not always the go-to choice, flat cables offer unique attributes beyond their form factor. They provide a versatile set of solutions to various design challenges, a fact that may not be widely recognized in the engineering field. Flat cables offer more than just an alternate shape; they bring a suite of advantageous features to the table for solving complex design issues.

What's the difference between a round cable and a flat cable?

Quality

Both round and flat cables are recognized for their high quality in appropriate applications. Round cables, however, generally offer a slightly superior quality, thanks to their robust built-in protections that enhance durability and lifespan, especially in rigorous industrial environments.

Reliability

In terms of withstanding mechanical stresses like torsion, rolling flex, tic-toc, and S-bend, round cables typically exhibit greater reliability. This is due to their capacity to flex along various axes. Flat cables, while offering enhanced resistance in situations involving rolling flex (bending along a single axis), are noted for their simpler, more orderly wiring, which tends to reduce the occurrence of malfunctions.

Performance

In their respective operational environments, both round and flat cables perform admirably. However, round cables tend to outperform in terms of electrical efficacy and physical robustness in heavy-duty applications. They offer increased durability and better shielding against environmental elements, mechanical stress, and electromagnetic interference. On the other hand, flat cables may encounter some limitations in electrical aspects due to their design, primarily intended for mass termination in connectors.